A1.3 transducer block – Yokogawa EJA115 User Manual

Page 43

IM 01C22T02-01E

A-5

APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF THE EJA

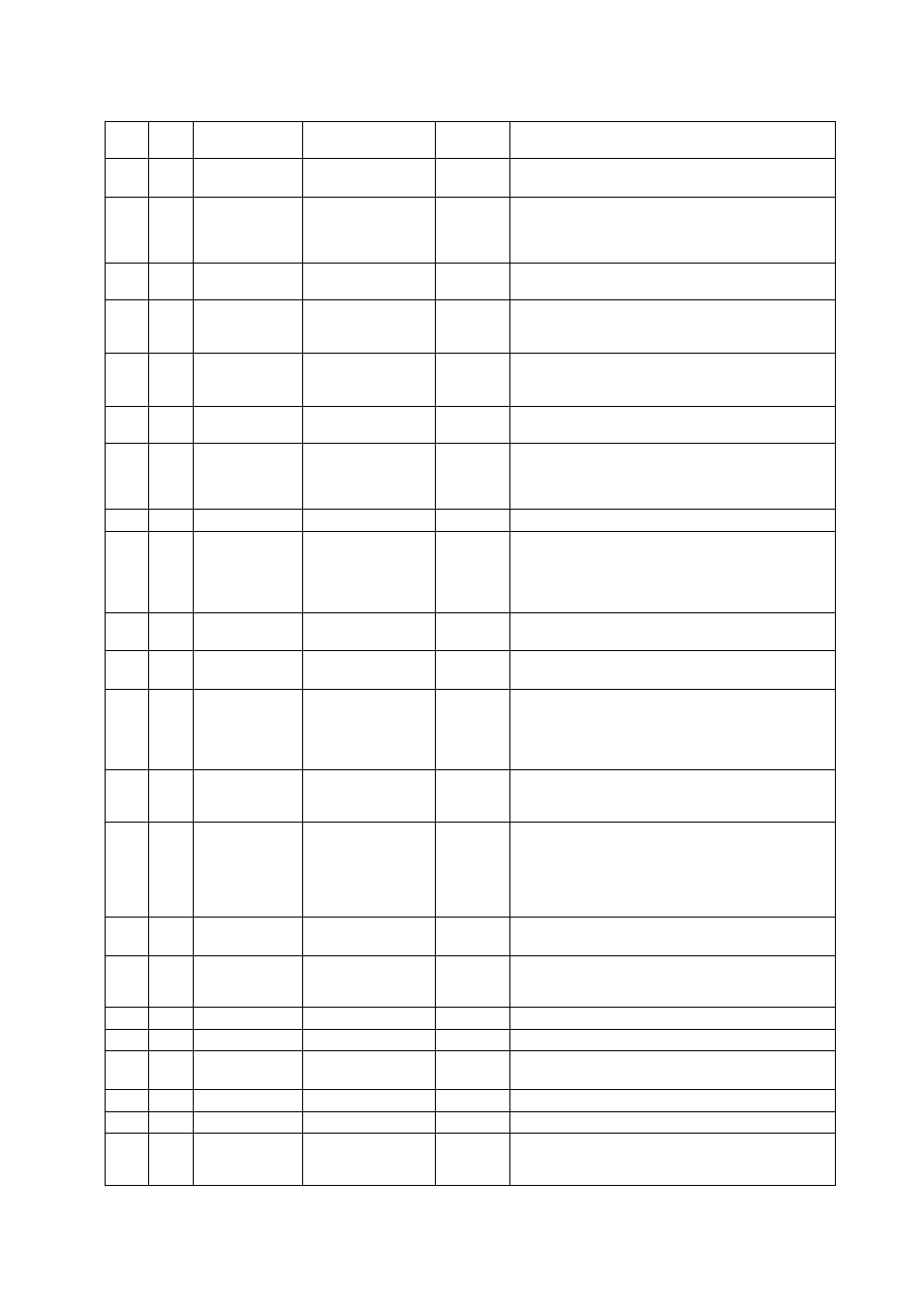

A1.3 Transducer Block

Relative

Index

Index

Explanation

Write Mode

Factory Default

Parameter Name

0

2000

TAG: “TB”

Block Header

Information on this block such as Block Tag, DD

Revision, Execution Time etc.

Block Tag

= O/S

1

2001

–

ST_REV

The revision level of the static data associated with the

function block. The revision value will be incremented

each time a static parameter value in the block is

changed.

–

2

2002

(blank)

TAG_DESC

The user description of the intended application of the

block

AUTO

3

2003

1

STRATEGY

The strategy field can be used to identify grouping of

blocks. This data is not checked or processed by the

block.

AUTO

4

2004

1

ALERT_KEY

The identification number of the plant unit. This

information may be used in the host for sorting alarms,

etc.

AUTO

5

2005

AUTO

MODE_BLK

The actual, target, permitted, and normal modes of the

block.

AUTO

6

2006

–

BLOCK_ERR

This parameter reflects the error status associated with

hardware or software components associated with a

block. It is a bit string, so that multiple errors may be

shown.

–

7

2007

–

UPDATE_EVT

This alert is generated by any change to the static data.

–

8

2008

–

BLOCK_ALM

The block alarm is used for all configuration, hardware,

connection failure or system problems in the block. The

cause of the alert is entered in the subcode field. The

first alert to become active will set the Active status in

the Status attribute.

–

9

2009

–

TRANSDUCER_

DIRECTORY

A directory that specifies the number and starting

indices of the transducers.

–

10

2010

100 (Standard Pre-

ssure with Calibration)

TRANSDUCER_

TYPE

Identifies transducer.

–

11

2011

–

XD_ERROR

The error code in transducer.

0=No failure

20=Electronics failure

22=I/O failure

21=Mechanical failure

–

12

2012

–

COLLECTION_

DIRECTORY

A directory that specifies the number, starting indices,

and DD Item Ids of the data collections in each

transducer within a transducer block.

–

13

2013

107: differential

pressure

108: gauge pressure

109: absolute pressure

PRIMARY_

VALUE_TYPE

The type of measurement represented by primary

value.

Followings are available for EJA:

107=differential pressure

108=gauge pressure

109=absolute pressure

O/S

14

2014

–

PRIMARY_

VALUE

The measured value and status available to the function

block.

–

15

2015

Range of capsule

PRIMARY_

VALUE_RANGE

The High and Low range limit values, engineering units

code and the number of digits to the right of the decimal

point to be used to display the primary value.

–

18

2018

Minimum span of

capsule

CAL_MIN_SPAN

The minimum calibration span value allowed.

–

16

2016

Max range

CAL_POINT_HI

The highest calibrated value.

O/S

17

2017

0

CAL_POINT_LO

The lowest calibrated value.

O/S

21

2021

Range of capsule

SENSOR_RANGE

TA0103-1.EPS

The High and Low range limit values, engineering units

code and the number of digits to the right of the decimal

point for the sensor.

–

19

2019

kPa

CAL_UNIT

The engineering unit for the calibrated values.

–

20

2020

Silicon resonant

SENSOR_TYPE

The type of sensor.

–