Ul/c-ul approval – Proface AGP3500 - 10.4 DIO HMI" User Manual

Page 15

15

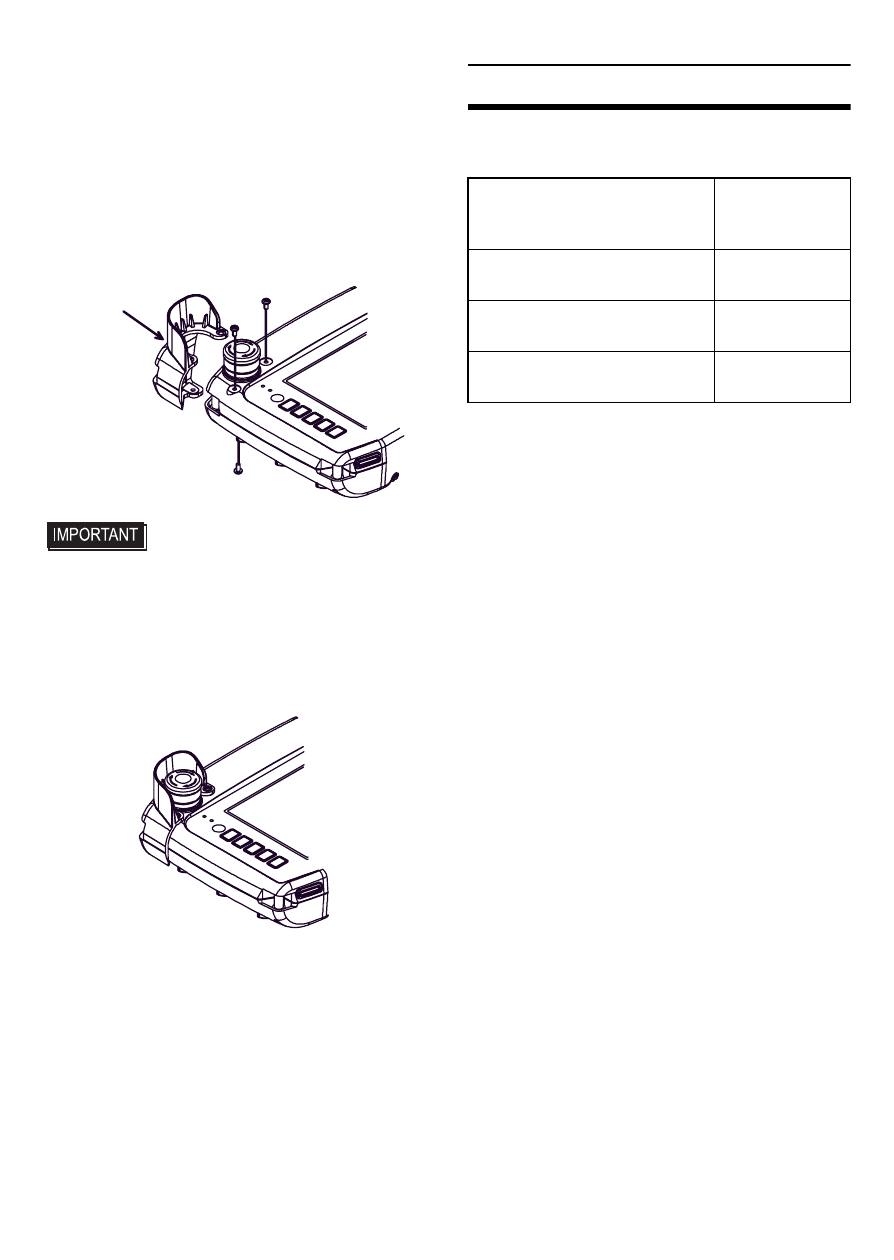

(3) Align the three screw holes of the

emergency switch guard with the screw

holes of the GP unit, and fasten the two

points in the front, and the one point in

the rear of the GP unit with screws.

• Tightening each screw with excessive

torque may result in damage to the

equipment. Appropriate tightening

torque is 0.5 N·m.

(4) The following is the complete mounting

configuration:

UL/c-UL Approval

The following units are UL/c-UL listed

products

*1

: (UL File No.E220851)

These products conform to the following

standards:

UL508

Industrial Control Equipment

CSA-C22.2 No.142-M1987

(c-UL Approval)

Industrial Control Equipment

Be aware of the following items when

building the GP into an end-use product:

• The GP unit must be used indoors only.

*1 The system constructing the following

three components conform to UL/c-UL

standards:

• GP3000H

• GP3000H Direct-connect Cable (with

connector)

GP3000H-CBLHD-10M, GP3000H-

CBLSD-3M, GP3000H-CBLSD-5M,

GP3000H-CBLSD-10M

• GP3000H Conversion Adapter

AGP3000H-ADPCOM-01

First, align the screw

holes of the

emergency switch

guard with those of the

GP unit.

Fasten the two

points in the front,

and the one point in

the rear of the GP

unit with screws.

Product Model No.

UL/c-UL

Registration

Model No.

AGP3300H-L1-D24

3610005-03

AGP3300H-S1-D24

3610005-02

AGP3310H-T1-D24

3610005-01

- AGP3400 - 7.5 DIO HMI" AGP3300 - 5.7 DIO HMI" AGP3600 - 12.1 FLEX Network HMIs" AGP3500 - 10.4 FLEX Network HMI" AGP3400 - 7.5 FLEX Network HMI" AGP3600 - 12.1 CANopen HMI" AGP3500 - 10.4 CANopen HMI" AGP3400 - 7.5 CANOpen HMI" AGP3300 - 5.7 CANopen HMI" AGP3300H - 5.7 Handheld HMIs" AGP3750 - 15 Multi-Media HMI" AGP3650 - 12.1 Multi-Media HMIs" AGP3550 - 10.4 Multi-Media HMIs" AGP3450 - 7.5 Multi-Media HMI" AGP3360 - 5.7 Multi-Media HMI" AST3300 - 5.7 Basic HMI" AST3200 - 3.8 Basic HMI" AGP3600 - 12.1 Standard HMIs" AGP3500 - 10.4 Standard HMIs" AGP3400 - 7.5 Standard HMI" AGP3300 - 5.7 Standard HMI" AGP3200 - 3.8 Standard HMI"