IAI America IX-NNW8040 User Manual

Page 71

65

7. Specifi

cations

Item

Specifications

Temperature: 0 to 40 C, humidity: 20 to 85%RH or less (non-condensing)

Altitude

m

1,000 or less

B

d

e

s

i

o

N

73

Robot weight

kg

34.5

Air purge pressure (*11)

0.05 to 0.6 MPa

Protection class

IP65 or equivalent

230 V 50/60 Hz 8 A

Allowable supply voltage fluctuation

%

10

Overvoltage category (IEC60664-1)

Category III

Pollution degree (IEC60664-1)

Pollution degree 3

*1

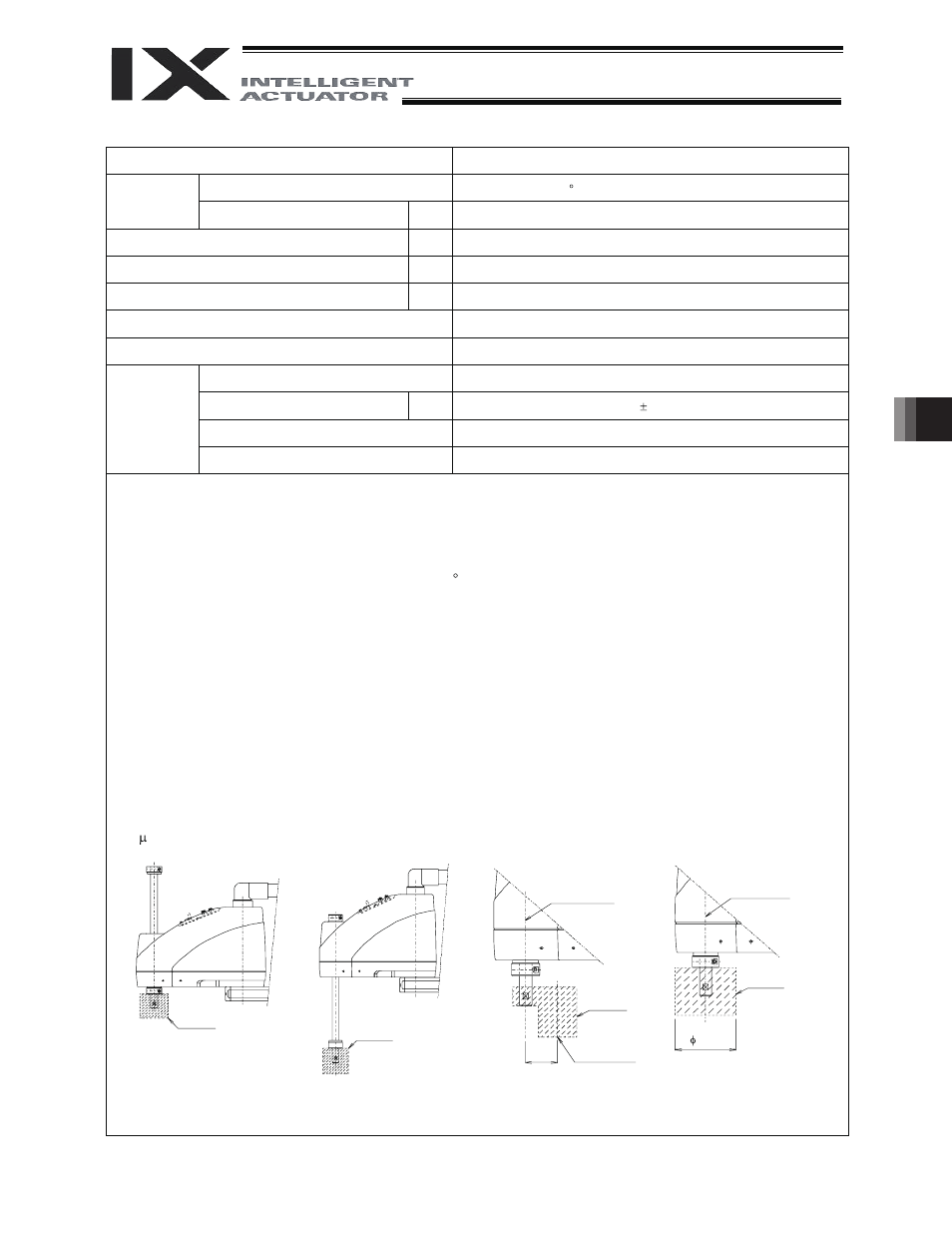

To move the robot horizontally at high speed, perform teaching so that the vertical axis stays as close to the top

position as possible. (Fig. 1)

To operate the robot with its vertical axis at the bottom position, the speed and acceleration must be reduced as

appropriate. (Fig. 2)

*2

Assuming PTP instruction operation.

*3

Measured at a constant ambient temperature of 20 C.

*4

Measured when the robot is operated at the maximum speed, carrying a rated load of 2 kg.

*5

The permissible moment of inertia converted to a value at the rotational center of axis 4. The offset from the

rotational center of axis 4 to the tool’ s centerof gravity is assumed to be 50 mm or less. (Fig. 3)

If the tool’ s center of gravity is furt

her away from the rotational center of axis 4, the speed and acceleration must be

reduced as appropriate.

*6

If the tool exceeds the permissible diameter, it will contact the robot inside

the

robot’ s range of movement. (Fig. 4)

*7

To enable the alarm LED indicator, the user must provide a circuit that supplies 24 VDC to the LED terminal in the

user connector in response to the controller I/O output signal, etc.

*8

A force of up to three times the dynamic push-in thrust may be applied at any given moment.

*9

The static thrust refers to thrust generated within the robot’ s range of operation based on a PAPR command.

*10 Pins 1 to 23 of the connector can be used. Pin 24 is connected to the shielded cable and cannot be used for signal

lines.

*11 Increase the pressure to a range of 0.05 and 0.6 MPa until immediately before the bellows starts to inflate, and

adjust the flow rate using the speed controller.

As a purge medium, use clean, dry air free from compressor oil, etc., corresponding to an air filtration rating of 10

m or below.

Reference design standards: Annex I to Machine Directives, EN292-1, EN292-2, EN1050, EN60204-1, EN775

Top position

Tool

Tool

Tool

Tool

Bottom

position

Center of

rotational axis

Center of

rotational axis

Tool’ s center of

gravity

(Fig. 1)

(Fig. 2)

(Fig. 3)

(Fig. 4)

50

100

Brake power source for main unit

W

24V DC ±10% 20W

Controller

Power supply

Operating

environment

Ambient temperature/humidity