Maintenance inspection, 1 inspection items and inspection schedule, 2 exterior cleaning – IAI America RCLE-GR5L User Manual

Page 40

34

14. Maintenance Inspection

To use the actuator in a good condition for a long term, it is recommended to have daily inspections

and also regular inspections.

14.1 Inspection Items and Inspection Schedule

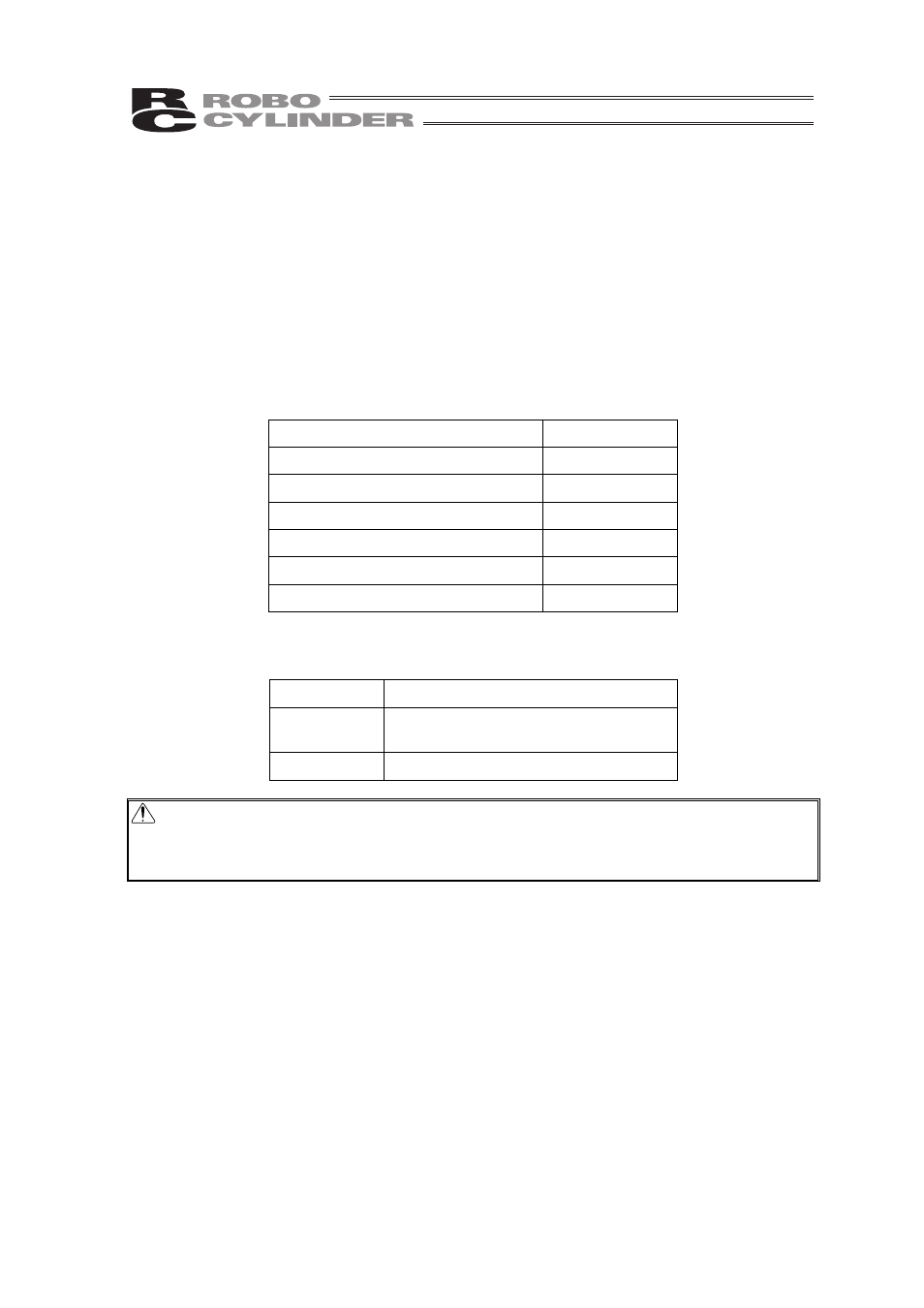

The standard maintenance inspection schedule is as described below.

The calculation is conducted under the condition that there are 8 working hours per day. Have

inspections more frequently if the operation frequency is high for night and day continuous

operation, etc.

Visual

inspection

At startup inspection

ż

1 month after start of operation

ż

6 months after start of operation

ż

1 year after start of operation

ż

Every 6 months thereafter

ż

Every year thereafter

ż

For the visual inspection, check the appearance following items.

Main Body

Looseness of attachment screws

Cables

Existence of damage and condition of

cable connections

Overall

Abnormal noise, vibration

Note : Do not dismantle the unit or cut the cables. Please contact us if it is considered

necessary to dismantle the unit for such reasons as a failure in operation.

The warranty to the operation and failure will be voided if a dismantlement or cable cut

is confirmed on the unit.

14.2 Exterior cleaning

Ɣ Please have cleaning of the external body at any time.

Ɣ When cleaning, wipe with a soft cloth to remove dust and dirt.

Ɣ To avoid dust getting inside the unit from small gaps, do not attempt to have compressed air

blown on the unit body.

Ɣ Do not apply petroleum solvent since it may damage the resin or painted surfaces.

Ɣ When it is extremely dirty, have neutral detergent applied on a soft cloth, and wipe off the dirt

firmly.