Allowable load condition – IAI America RCLE-GR5L User Manual

Page 32

26

10. Allowable Load Condition

10.1 Check Holding Force and Allowable Load Conditions

Follow the steps below:

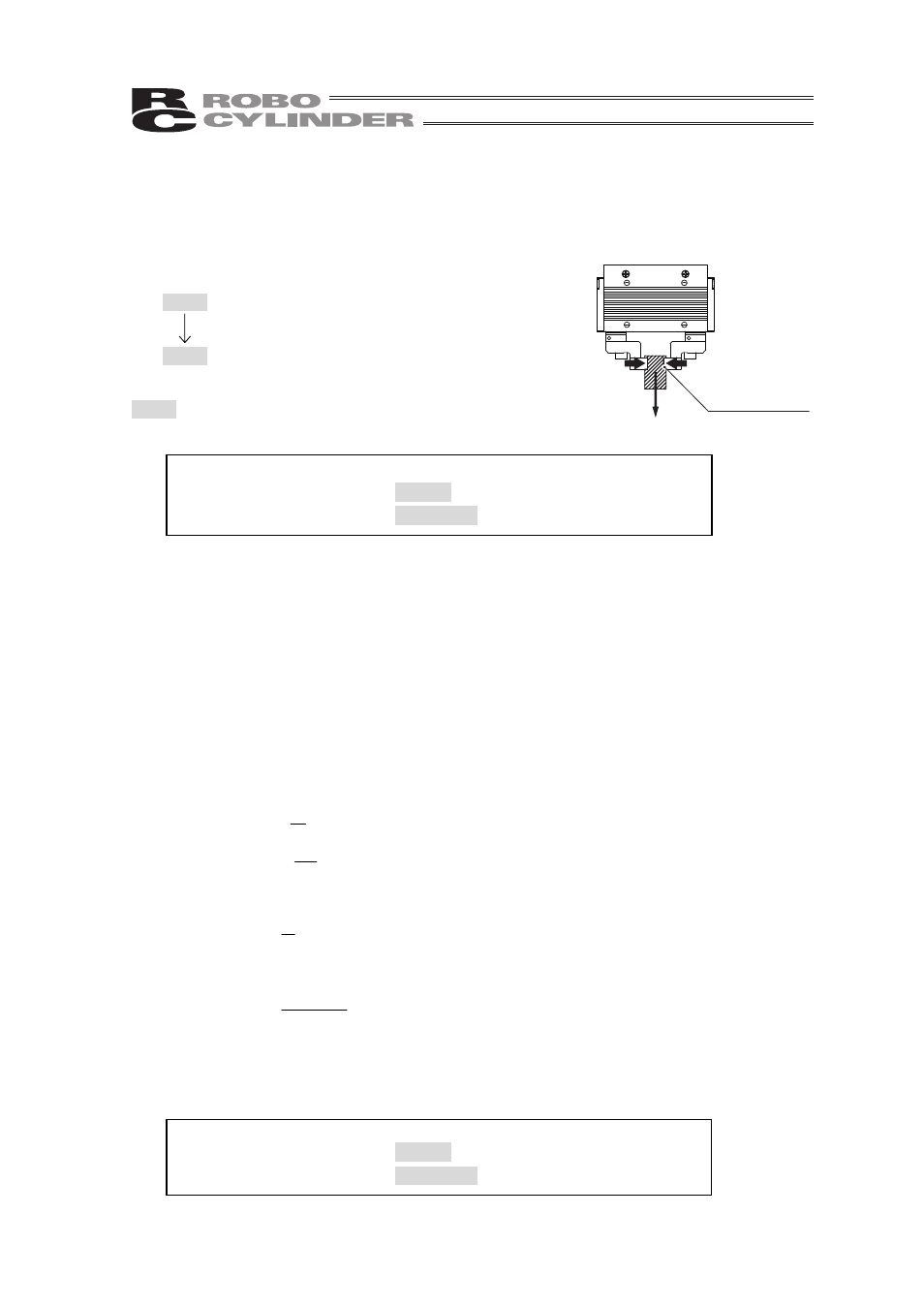

Step 1: Check the necessary holding force and the weight of

the work part

Step 2: Check the allowable vertical load of the fingers and

allowable moment

Step 1: Check the necessary holding force and the weight of the

work part

In ordinary work part movement

Necessary holding force

10 to 20 times the weight of the work part

Work part weight

1/10 to 1/20 or less of the holding force

As the calculation below shows, the weight of the work part capable to hold gets bigger as the

coefficient of friction gets larger. However, for safety reasons, have the holding force 10 to 20

times more than the work part weight regardless of the coefficient of friction.

(Calculation Example) Here, figure out the necessary holding force when gripping the work part

with the friction force.

(1) In ordinary travel

F : Gripping Force [N]……Total value of the pressing force of each finger

W : Work part weight [kgf]

P : Coefficient of static friction between finger attachments and work part

m : Work part mass [kg]

g : Acceleration of gravity [

9.8m/s

2

]

The condition when the work part is held firmly and work part would not drop is:

F

P !

W

g

F

!

mg

ȝg

The necessary holding force in ordinary travel considering a recommended safety factor

of 2 is:

F

!

m

P

u 2 (Safety Margin)

Assuming the coefficient of friction

P is 0.1 to 0.2:

F

!

m

0.1 to 0.2

u 2 (10 to 20) u m

(2) When large acceleration or impact is applied during work part movement.

It will apply bigger inertial forces to the work part as well as gravity. In such a case,

consider more holding force and a larger safety factor.

When large acceleration/deceleration or impact is applied

Necessary holding force

30 to 50 times the weight of the work part

Work part weight

1/30 to 1/50 or less of the holding force

F

F

W [mg]

Coefficient of

Friction [

μ]