Part 15, Maintenance, A. maintenance procedures – HTP ELP-199 User Manual

Page 73: Part 15 – maintenance

73

LP-294 REV. 2.20.14

DISPLAY

CODE

ERROR

INT.

CODE

DESCRIPTION

POSSIBLE SOLUTION

No Code

Flame goes off at down

modulation after good

ignition

No Code

Ionization is not high enough

Check appliance type settings. Check

ionization pin position. Clean pin. Check

gas pressure during modulation. Check

air pressure chart peak at low fire.

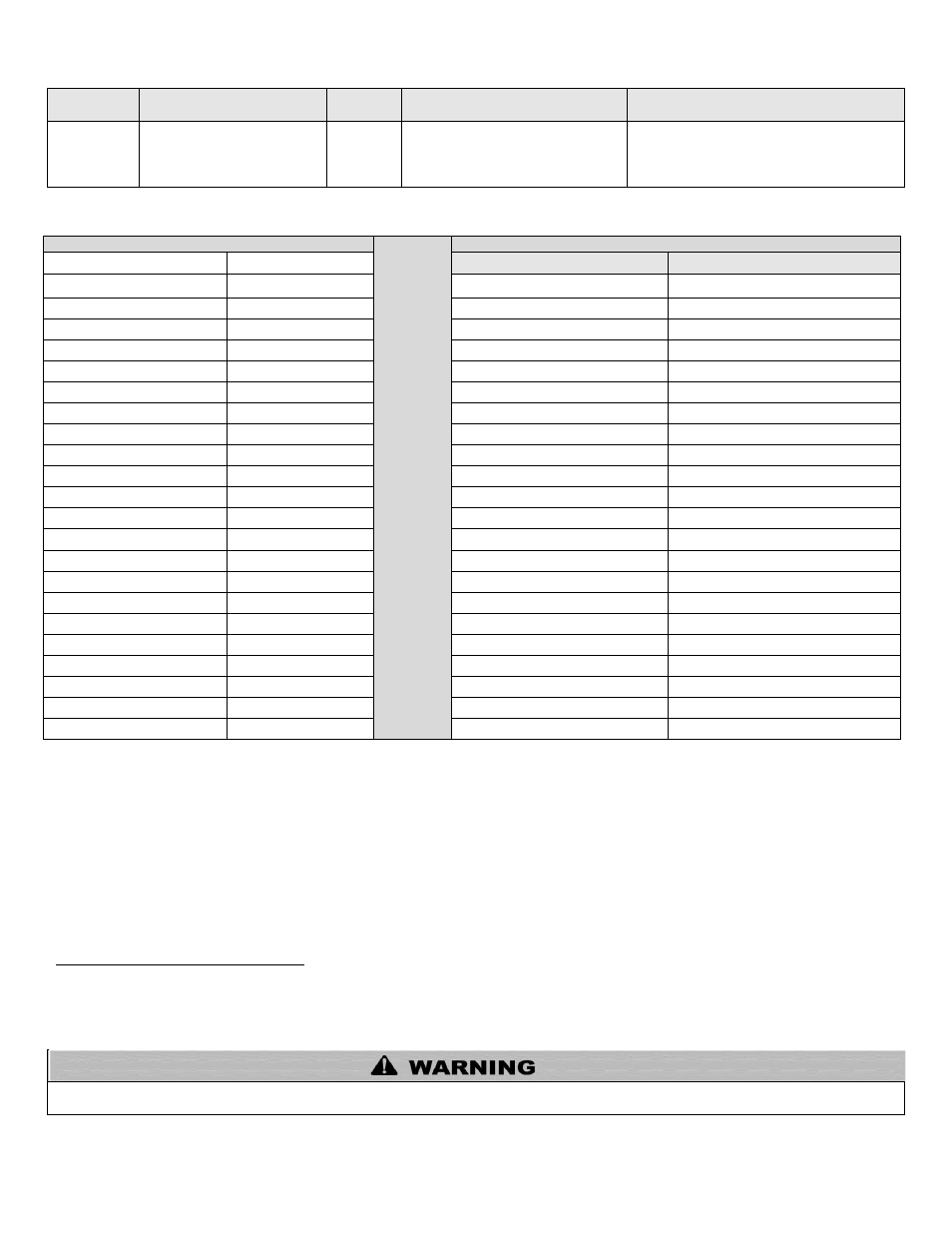

Table 46

– Error without Displayed Code

Resistance Tables

PART 15 – MAINTENANCE

A. MAINTENANCE PROCEDURES

Periodic maintenance should be performed once a year by a qualified service technician to assure that all the equipment is operating

safely and efficiently. The owner should make necessary arrangements with a qualified heating contractor for periodic maintenance of

the boiler. The installer must also inform the owner that a lack of proper care and maintenance of the boiler may result in a hazardous

condition.

BEFORE EACH HEATING SEASON a trained and qualified service technician should perform the inspections as per the boiler

inspection and maintenance schedule in the back of the manual. Failure to do so could result in death or serious injury.

Outdoor Sensor (7250P-319)

Supply Temperature Sensor (7250P-324)

Outside Temperature (

o

F)

Resistance (ohms)

Boiler Sensor (7250P-667)

Indirect Sensor (7250P-325)

-22

171800

Outside Temperature (

o

F)

Resistance (ohms)

-13

129800

32

32550

-4

98930

41

25340

5

76020

50

19870

14

58880

59

15700

23

45950

68

12490

32

36130

77

10000

41

28600

86

8059

50

22800

95

6535

59

18300

104

5330

68

14770

113

4372

77

12000

122

3605

86

9804

131

2989

95

8054

140

2490

104

6652

149

2084

113

5522

158

1753

167

1481

176

1256

185

1070

194

915

203

786

212

667

Table 47

– Resistance Tables