A. boiler error codes, B. user interface display, Lockout error codes – HTP ELP-199 User Manual

Page 70

70

LP-294 REV. 2.20.14

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN SUBMERGED IN WATER. Immediately call a qualified service technician.

The appliance MUST BE replaced if it has been submerged. Attempting to operate an appliance that has been submerged could create

numerous harmful conditions, such as a potential gas leakage causing a fire and/or explosion, or the release of mold, bacteria, or other

harmful particulates into the air. Operating a previously submerged appliance could result in property damage, severe personal injury,

or death.

NOTE: Appliance damage due to flood or submersion is considered an Act of God, and IS NOT covered under product warranty.

This boiler has wire function labels on all internal wiring. Observe the position of each wire before removing it. Wiring errors may cause

improper and dangerous operation. Verify proper operation after servicing.

If overheating occurs, or the gas supply fails to shut off, do not turn off electrical power to the circulating pump. This may aggravate the

problem and increase the likelihood of boiler damage. Instead, shut off the gas supply to the boiler at the gas service valve.

A. BOILER ERROR CODES

The display may show an error message and error code if any of the sensors detect an abnormal condition or an internal component

fails during the operation of the boiler, and the condition lasts longer than one second.

This message and code may be the result of a temporary condition, in which case the display will revert to its normal readout when the

condition is corrected

. This is known as a “Blocking” error, and will be indicated as such on the display with the letter “E”.

The code may also be the result of a condition that the controller has evaluated as not safe to restart the boiler. In this case, the boiler

control will be locked out, the red FAULT light will be lit, and the mes

sage “LOCKOUT” will be displayed on the display readout, along

with the letter “A”. In the case of a “LOCKOUT” error, the boiler will not start until a qualified technician has repaired the boiler and

pressed the RESET button for more than 1 second.

IMPORTANT NOTE: If you see error messages on your display readout, call a technician immediately, since the message may indicate

a more serious problem will occur soon.

B. USER INTERFACE DISPLAY

NOTE: If flame goes out after proper ignition and the boiler displays an error after too many flame failures, check the appliance type.

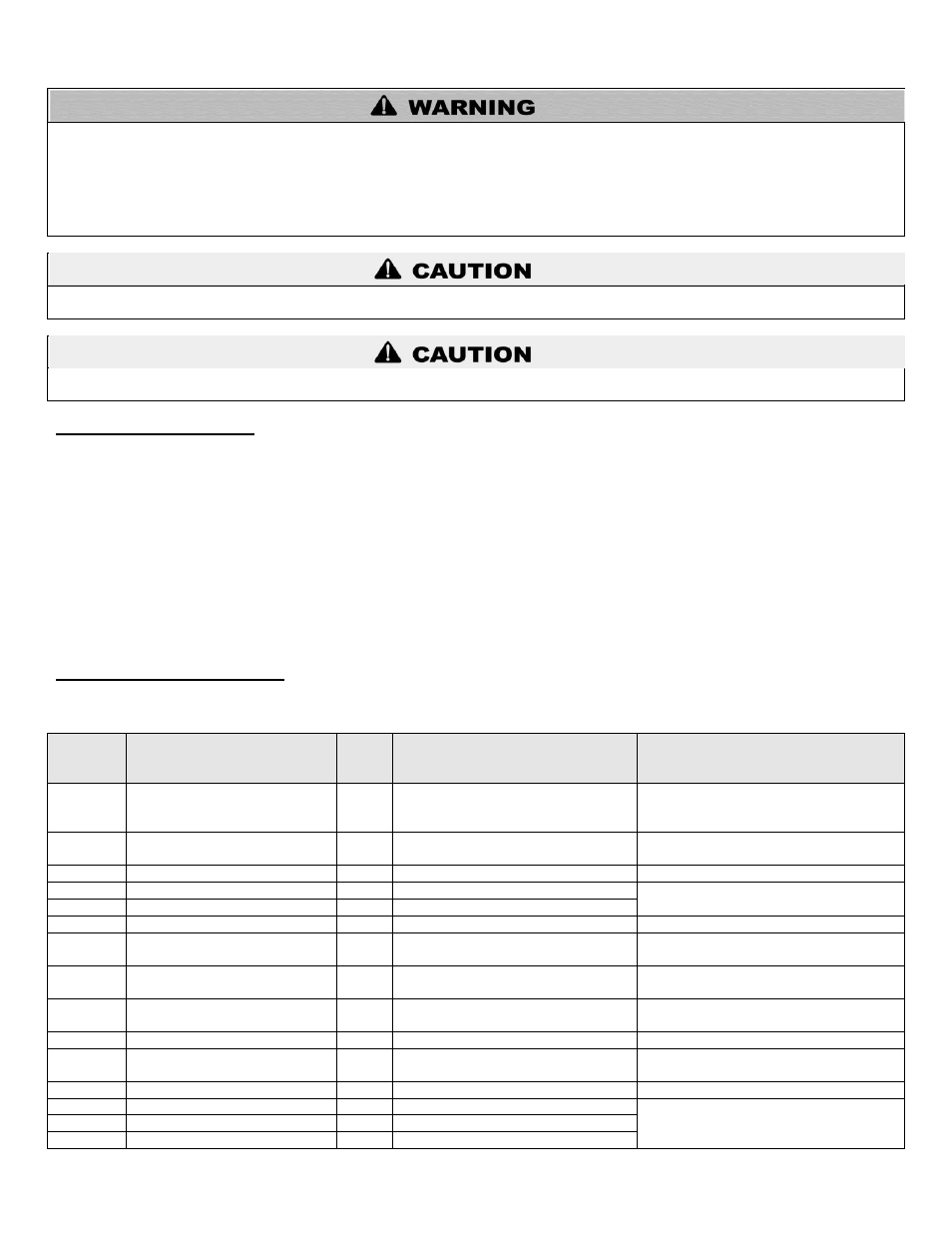

1. LOCKOUT ERROR CODES

DISPLAY

CODE

ERROR

INT.

COD

E

DESCRIPTION

POSSIBLE SOLUTION

A01

IGNIT_ERROR

1

Five unsuccessful ignition attempts

in a row

Check ionization and spark electrode.

Check gas pressure. Check plugs at

gas valve and stepper motor.

A05

GV Relay Error

2

Failure detected in the GV Relay

Check gas valve plug and windings

–

resistance. If correct, exchange BCU.

A05

GV Relay not open error

3

Failure detected in the GV Relay

BCU must be exchanged.

A05

GV Relay not closing error

4

Failure detected in the GV Relay

Check gas valve plug and windings

–

resistance. If correct, exchange BCU.

A06

Safety relay error

5

Failure detected in the Safety Relay

A06

Safety relay open error

6

Failure detected in the Safety Relay

BCU must be exchanged.

A06

Safety relay closed error

7

Failure detected in the Safety Relay

Check gas valve plug and windings

–

resistance. If correct, exchange BCU.

A00

Blocking too long error

11

Control had a blocking error for

more than 20 hours in a row.

Reset the boiler and repair the blocking

error.*

A08

Fan error

12

Fan MF deviation for more than 60

sec. to target MF.

Check exhaust gas piping. Exchange

fan.*

A09

Ram error

13

Internal software error

Exchange BCU.

A10

Wrong eeprom signature

14

Contents of e2prom is not up-to-date

Reload the E2Prom if possible,

otherwise exchange BCU.

A11

X ram error

15

Internal software error

Exchange BCU.

A12

E2prom error

16

No communication with E2prom

Reload the E2Prom if possible,

otherwise exchange BCU.

A12

E2prom error safety C

17

Wrong safety parameters in E2prom

A12

E2prom error Calibration table

18

Wrong calibration table parameters