F. system test, G. lambda constant – HTP ELP-199 User Manual

Page 65

65

LP-294 REV. 2.20.14

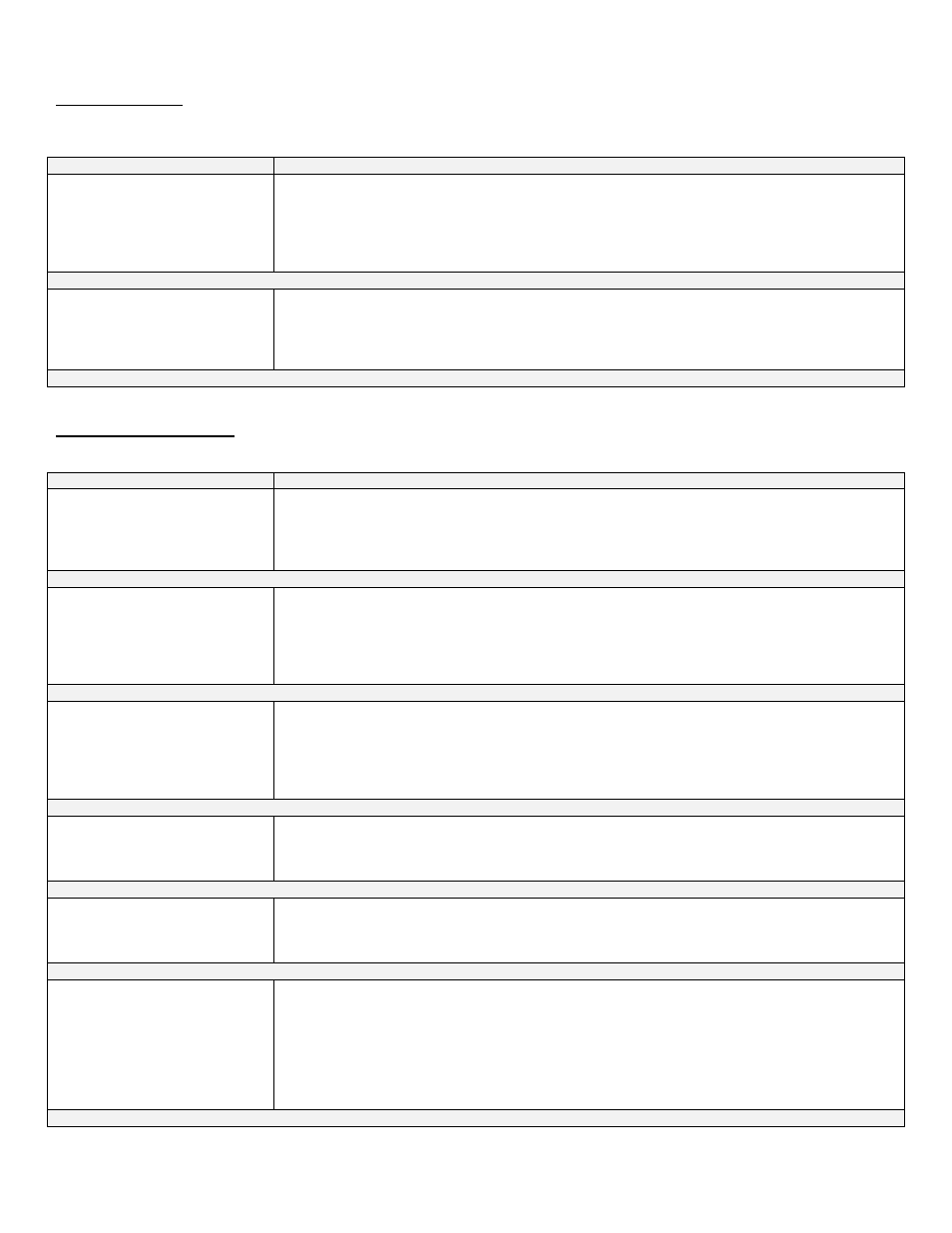

F. SYSTEM TEST

All functions of Test Mode are stopped after 30 minutes if not stopped manually. In cascade mode, the boiler address must be

set to “0”

before activating the system test.

SCREEN

DESCRIPTION

SYSTEM TEST

Set Test Power

Off

Options: Off = Boiler runs in normal operation

Low Power = Boiler runs at minimum modulation range which can be influenced by the load

adaptation

Ignit Power = Boiler runs at ignition modulation range

High Power = Boiler runs at maximum modulation range which can be influenced by the load

adaptation.

Pressing the

▼ key allows the Installer to view more data.

SYSTEM TEST

>General Pump Off

CH-Pump Off

DHW-Pump Off

This allows the installer to test system pumps.

Options: Off = Pumps run controlled by the boiler

On = Pumps start running in test mode

Either the CH-Pump/3WV or the DHW-Pump/3WV run at the same time. In this option, it is also

possible to switch a 3WV in CH or DHW position.

Press the

▲ key to view return to the previous screen.

Table 30

– Installer Menu – System Test Screens

G. LAMBDA CONSTANT

These settings should only be modified by qualified personnel.

SCREEN

DESCRIPTION

LambdaConstant

Gas Type

Selection

NG

Allows the installer to select gas supply.

Options:

NG = Natural gas, Methane

LPG = Liquid Pressurized Gas, Propane, Butane

Default is NG.

Pressing the

▼ key allows the Installer to view and/or adjust more data.

LambdaConstant

Min. Mass Flow

Temp. Deviation

_0K

Allows the installer to adjust CO

2

at low power. Before making any adjustment, it is recommended

to run the boiler in system test at low power. If the CO

2

is not within specification, use this

parameter to adjust while measuring the CO

2

. The default value is 0. Increasing this value will

increase CO

2

. Decreasing the value will decrease the CO

2

.

NOTE: The range is -128 to +128. Change the value a small amount at a time to avoid wide

swings in CO

2

measurements.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

LambdaConstant

Max. Mass Flow

Temp. Deviation

_0K

Allows the installer to adjust CO

2

at high power. Before making any adjustment, it is recommended

to run the boiler in system test at high power. If the CO

2

is not within specification, use this

parameter to adjust while measuring the CO

2

. The default value is 0. Increasing this value will

increase CO

2

. Decreasing the value will decrease the CO

2

.

NOTE: The range is -128 to +128. Change the value a small amount at a time to avoid wide

swings in the CO

2

.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

LambdaConstant

Prepurge Initial

Speed

3460rpm

The prepurge fan speed is measured during the first three complete heat demand cycles on the

boiler. The average fan speed is stored and displayed here. The default value is 0. The number 0

is displayed before 3 successful heat demands are completed.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

LambdaConstant

Prepurge Actual

Speed

3420rpm

This is the prepurge fan speed of the last ignition. If this speed is not close to the Prepurge Initial

Speed displayed in the screen above, a

n “MF deviation Error” occurs. This error signals a

significant change in the air inlet, flue system, or possible heat exchanger blockage.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

LambdaConstant

Prepurge Initial

Speed Reset please

Switch off 0rpm

After checking the boiler, air intake, and flue system for blockage or other failure and measuring

the CO

2

values at low and high power, the installer can reset the Prepurge Initial Speed. To reset

the prepurge initial speed:

1. Press ENTER. The RPM number will begin to blink.

2. Press the

▼ key. The RPM number will go to 0.

3. Press ENTER again and the 0 RPM will stop blinking.

4. Turn boiler power off and wait 30 seconds.

5. Turn boiler power on again for the reset to occur.

Table 31

– LambdaConstant Screens