J. check/control water chemistry, Multiple boiler manifold piping – HTP ELP-199 User Manual

Page 25

25

LP-294 REV. 2.20.14

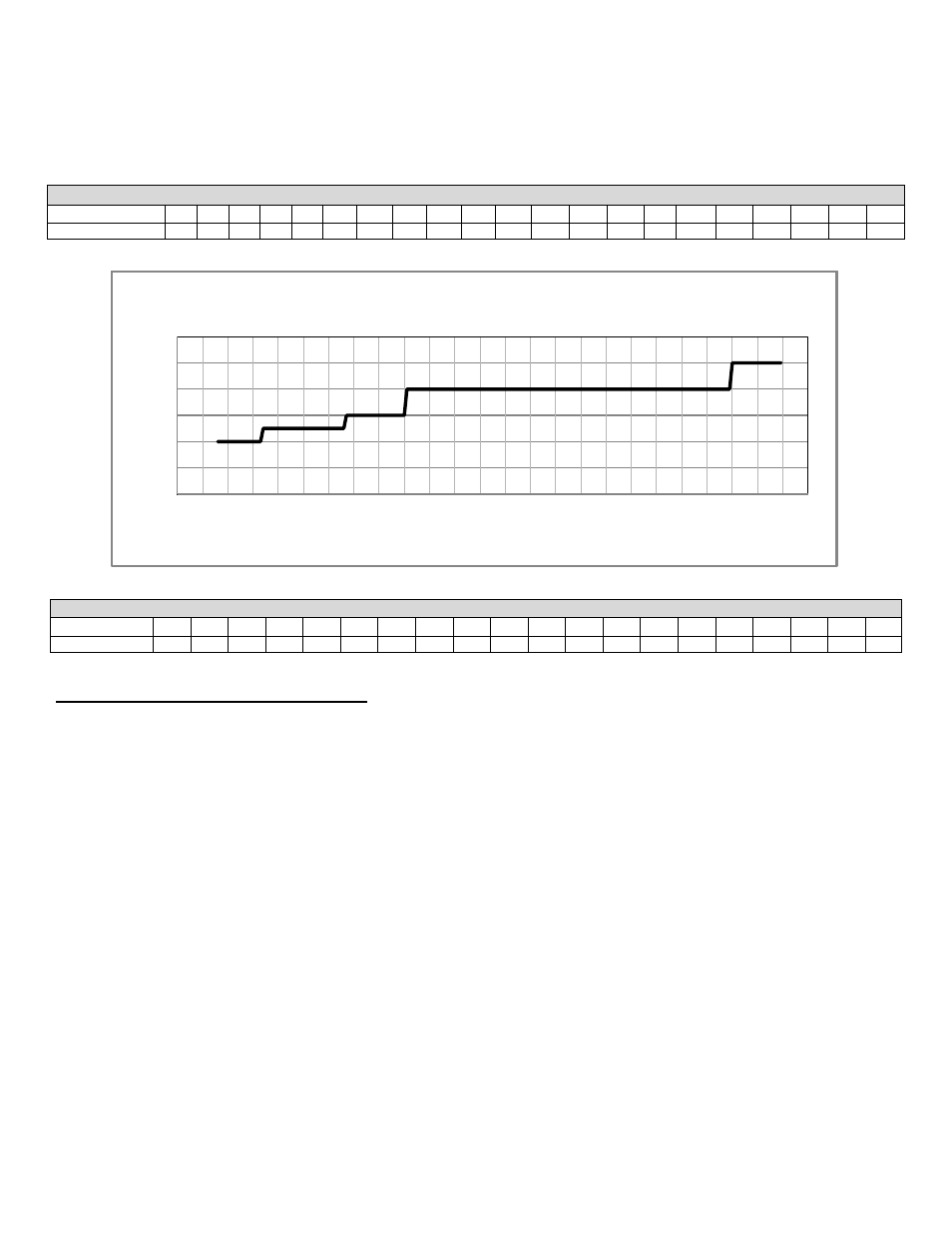

Tables 8 and 9 represent combined flow rates and pipe sizes when using multiple boilers to design the primary circuit manifold system.

To size, simply add the number of boilers and the required flow rates for the system design temperature.

Example: (5) ELP-199® boilers with a design of 20°

Δt temperature rise with each boiler having an individual flow rate of 22 GPM. To

correctly size the manifold feeding these (5) boilers,

you would need a pipe size of 4”.

MULTIPLE BOILER MANIFOLD PIPING

Flow Rate (GPM)

16

22

24

30

32

33

40

44

45

48

50

55

60

66

75

80

85

88

90

100

110

Pipe Dia. (Inches)

2

2

2

2

2

2½

2½

2½

2½

2½

2½

2½

2½

2½

3

3

3

3

3

3

4

Table 8

Figure 10

MULTIPLE BOILER MANIFOLD PIPING

Flow Rate (GPM)

120

132

150

160

170

179

200

210

239

240

250

255

300

340

350

400

425

510

595

680

Pipe Dia. (In.)

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

5

6

6

6

Table 9

J. CHECK/CONTROL WATER CHEMISTRY

NOTE: BOILER FAILURE DUE TO IMPROPER WATER CHEMISTRY IS NOT COVERED BY WARRANTY.

Sodium less than 20 mGL

Water pH between 6.0 and 8.0

1. Maintain boiler water pH between 6.0 and 8.0. Check with litmus paper or have chemically analyzed by water treatment company.

2. If pH differs from above, consult local water treatment company for treatment needed.

Hardness less than 7 grains

Consult local water treatment companies for unusually hard water areas (above 7 grains hardness).

Chlorine concentration less than 100 ppm

1. Filling with chlorinated fresh water should be acceptable since drinking water chlorine levels are typically less than 5 ppm.

2. Do not use the boiler to directly heat swimming pool or spa water.

3. Do not fill boiler or operate with water containing chlorine in excess of 100 ppm.

Hardness: 7 grains

Chloride levels: 100 ppm

pH levels: 6-8

TDS: 2000 ppm

Sodium: 20 mGL

Clean system to remove sediment*

1. You must thoroughly flush the system (without boiler connected) to remove sediment. The high-efficiency heat exchanger can be

damaged by buildup or corrosion due to sediment.

0

1

2

3

4

5

6

0

50

100

150

200

250

Pi

p

e

Di

am

e

te

r Si

ze

(In

ch

e

s)

Combined Boiler Water Flow (GPM)

Multiple Boiler Manifold Piping