B. boiler configuration – HTP ELP-199 User Manual

Page 61

61

LP-294 REV. 2.20.14

B. BOILER CONFIGURATION

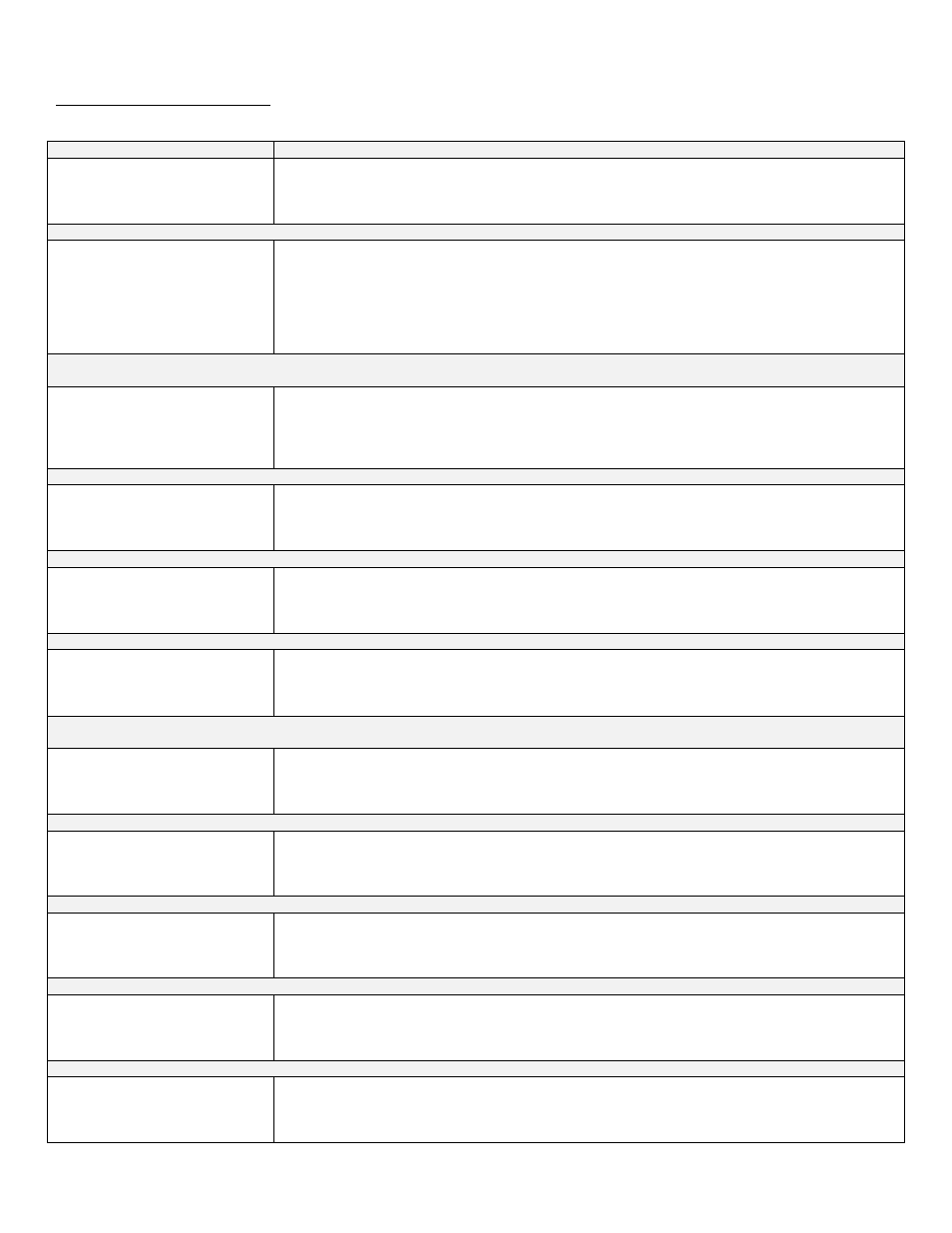

After selecting “Boiler Config” at the Installer Menu screen, the following options are available.

SCREEN

DESCRIPTION

BOILER CONFIG

Address Selection

Boiler Address 0

Allows Installer to choose a boiler address and set up a cascading system

. Selecting “0” = no

cascading system, “1” = managing boiler, “2 – 16” = follower boilers. Factory default is “0”. Range

is 0

– 16. After setting Cascade Master address, wait about a minute for the “Cascade Master”

LED to light.

Pressing the

▼ key allows the Installer to view and/or adjust more data.

BOILER CONFIG

Pump Mode 2

Manifold with CH

DHW and Gen. pump

Pump mode can be chosen by selecting the corresponding number. Pump modes are displayed

during selection in 2 lines. Options:

0 = CH and DHW pump

1 = General pump with 3 WV (not used)

2 = Manifold with CH Gen and DHW pump (not used)

3 = Manifold with Gen pump and 3WV (not used)

4 = Manifold with Sys Pump DHW ext (not used)

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

The following setting must only be changed if the BCU or display is replaced.

BOILER CONFIG

Appliance Type

Model _1

The Appliance Type of Display and Burner Control Unit must be compatible. Ensure the correct

burner and blower are installed with the boiler.

Model 1 = Refers to 110 kBTU boiler

Model 2 = Refers to 199 kBTU boiler

Default depends on the boiler.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

Service Reminder

>STATUS ON

Reminder 365 days

This screen allows the installer to set a fixed time period until the service reminder appears. This

option can be switched ON or OFF. When changing the number of days, the reminder is initialized

and restarted.

Default setting is ON and 365 days. Range: On or Off, 0

– 365 days.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

Telefone Number

for Service

of Installer

The installer can set a telephone number to appear when service is necessary. Default value is “of

installer” when all are blank. All numbers “()*+,-./0..9 and blank” can be scrolled with the arrow

keys. Pressing the key cancels all changes. ENTER confirms. RESET changes any value back

to “blank”, or when “blank”, goes to “0” for faster editing.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

THERMISTOR TYPE

>Outdoor NTC 12k

All Others NTC 10k

This screen allows the installer to switch temperature sensor types from “NTC 10k” and “NTC

12k”.

Options: NTC 10k and NTC 12k.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

The following screens describe optional sensors and switches that can be installed to customize the installation.

BOILER CONFIG

Connector Input

J16 1-4

LowWaterCO

This screen shows a connector input at the burner control unit. Options: Disabled = No input

connected. LowWaterCO = A low water cut-off (NC) is connected. DHW FlowSW = Domestic hot

water flow switch with plate heat exchanger. CH FlowSW = Flow switch for central heating. Factory

default is LowWaterCO.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

Connector Input

J16 2-3

Flue Pr SW

This screen shows a connector input at the burner control unit. Options: Disabled = No input

connected. Air FlowSW = An air flow switch (NO) is connected. Flue PrSW

– A flue pressure

switch (NC) is connected. Factory default is Flue PrSW.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

Connector Input

J16 6-7

Disabled

This screen shows a connector input at the burner control unit. Options: Disabled = No input

connected. Gas PrSW = A gas pressure switch is connected. Water PrSw = A water pressure

switch is connected. DHW Rotary = A rotary sensor for DHW with plate heat exchanger is

connected. Factory default is Disabled.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

Conn. Input J16 1-8

Blocked Drain

Enabled

This screen shows a connector input for a blocked drain sensor. Options: Disabled = No input

connected. Enabled = Blocked drain switch is enabled. J16 1

– J16 – 6 = ground. Factory default is

Enabled.

Pressing the

▼ or ▲ keys allows the Installer to view and/or adjust more data or return to the previous screen.

BOILER CONFIG

Conn. Input J5 6-14

Flue Gas

Switch

This screen shows a connector input for a flue gas screen. Options: Switch = Switch connected.

Sensor = Sensor is enabled. Factory default is Switch.