I. indirect sensor, J. optional 0-10 volt building control signal, K. system sensor (cascade master boiler only) – HTP ELP-199 User Manual

Page 46: L. wiring of cascade system communication bus

46

LP-294 REV. 2.20.14

2. Mount the outdoor sensor on an exterior surface of the building, preferably on the north side in an area that will not be affected by

direct sunlight and will be exposed to varying weather conditions. NOTE: For correct mounting procedures, follow instructions provided

with the sensor.

3. Connect the sensor to terminals 12 and 13, as shown in Figure 27.

NOTE: For correct mounting procedures, follow instructions provided with the sensor.

NOTE: If sensor wires are located in an area with sources of potential electromagnetic interference (EMI), the sensor wires should be

shielded, or the wires routed in a grounded metal conduit. If using shielded cable, the shielding should be connected to the common

ground of the boiler.

I. INDIRECT SENSOR

There is no connection required if an indirect water heater is not used in the installation.

1. The boiler will operate an indirect fired water heater with either a thermostat type aquastat installed in the indirect tank or an HTP

7250P-325 tank sensor. When a tank sensor is used, a demand for heat from the indirect water heater will be generated when tank

temperature falls below the user set point by more than the user selectable offset. The demand will continue until the sensor measures

that indirect water heater temperature is above the set point.

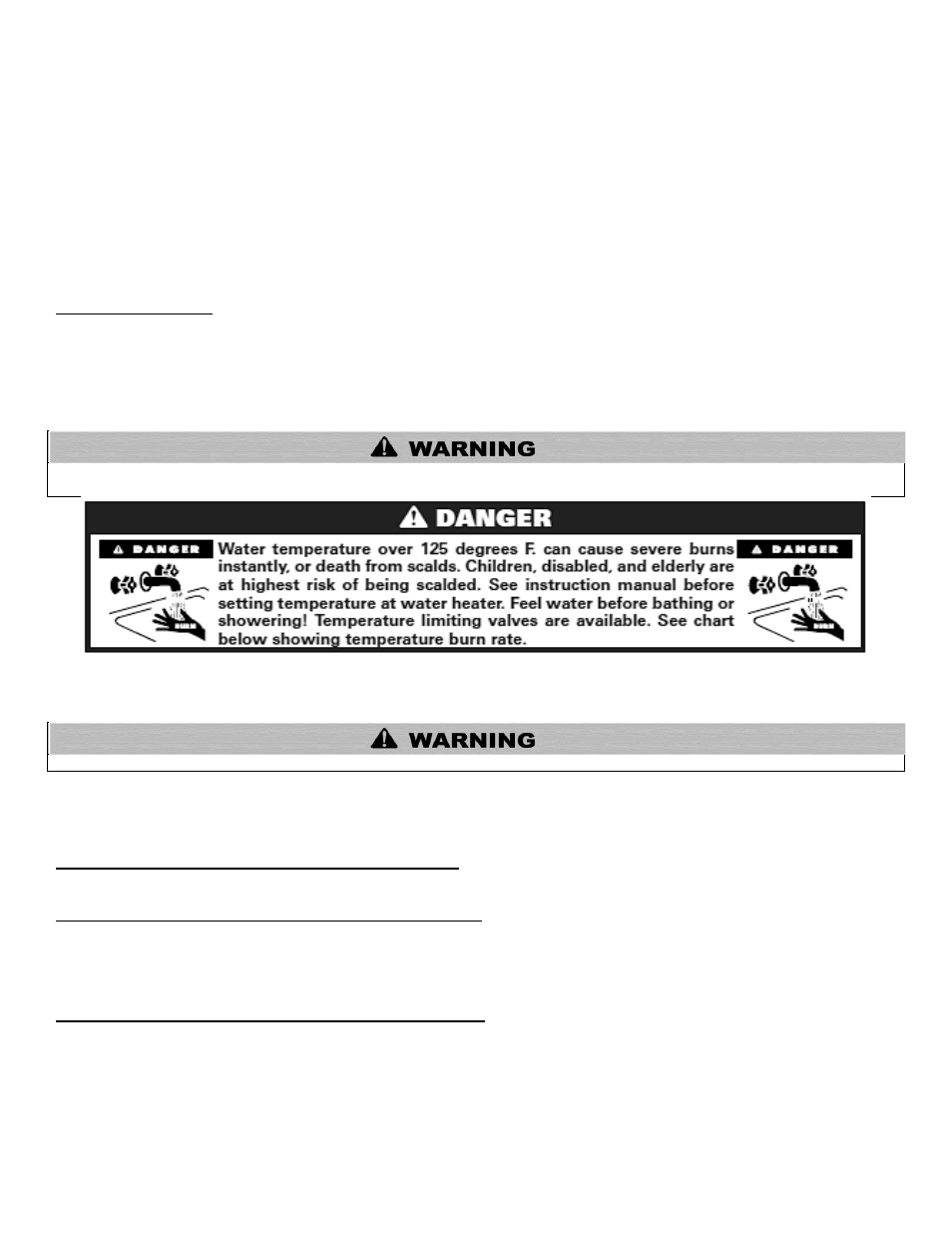

Failure to use the correct sensor may result in tank temperature being either above or below set point, and could result in decreased

performance, substantial property damage, or heightened risk of injuries due to scalds.

2. Connect the indirect sensor (7250P-325) to the terminals marked DHW SENSOR (10 and 11) (shown in Figure 27) in the electrical

junction box.

Take caution to ensure neither of these terminals becomes connected to ground.

NOTE: If sensor wires are located in an area with sources of potential electromagnetic interference (EMI), the sensor wires should be

shielded, or the wires routed in a grounded metal conduit. If using shielded cable, the shielding should be connected to the common

ground of the boiler.

J. OPTIONAL 0-10 VOLT BUILDING CONTROL SIGNAL

An optional Interface Module is available that provides a connection point for a 0

– 10 volt input.

K. SYSTEM SENSOR (CASCADE MASTER BOILER ONLY)

1. The system sensor must be installed on the piping at a point after the supply of all cascaded boilers is mixed together.

2. Connect the system sensor (7250P-324) to the terminals marked SYSTEM SENSOR (16 and 17) shown in Figure 27 in the cascade

master electrical junction box.

L. WIRING OF CASCADE SYSTEM COMMUNICATION BUS

1. Use standard CAT3 or CAT5

“Straight Through” computer network patch cables to connect the communication bus between each of

the boilers. These cables are readily available at any office supply, computer, electronic, department or discount home supply store in

varying lengths. If you possess the skills you can also construct custom length cables.

2. It is recommended to use the shortest length cable that will reach between the boilers and create a neat installation. Do not run

unprotected cables across the floor where they may become wet or damaged. Avoid running communication cables parallel and close

to or against high voltage (120 volt or greater) wiring. HTP recommends the maximum length of communication bus cables not exceed

200 ft.