The automotive vacuum system – Mityvac MV8500 silverline elite aUtoMotive test kit User Manual

Page 6

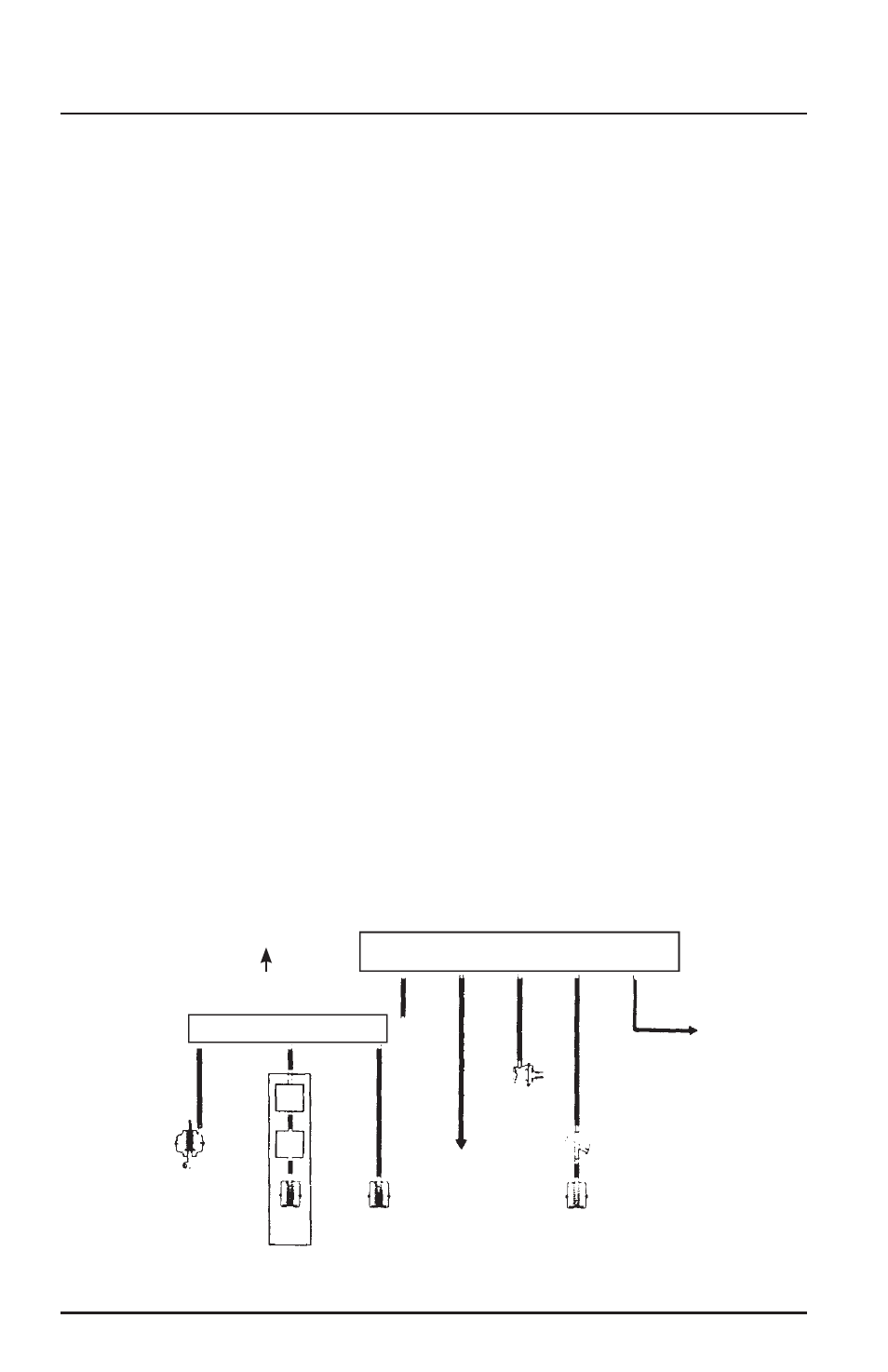

VACUUM DISTRIBUTION

All modern automobiles have a vacuum distribution

system (FIGURE 3), consisting of lines, hoses,

fittings and vacuum devices . This system must be

leak proof . If it is not, the engine air/fuel mixture

will be leaned out by the extra air entering the

system through the leaks, thus causing problems

such as burned exhaust valves, uneven idle, stalling,

pre-ignition, burned spark plugs, etc . Additionally,

any vacuum operated device affected by the

vacuum leak will not function properly .

A normal gasoline engine should develop 16-”

Hg of intake manifold vacuum at idle . This is an

indication that the engine is breathing properly .

If the vacuum is lower, the engine is running less

efficiently . The lower the manifold vacuum, the less

efficiently the engine is running and the lower the

gas mileage will be .

The vacuum distribution system supplies vacuum

to vacuum motors (servos) in the air conditioning,

power brake booster, speed control servo, emission

controls, manifold absolute pressure (MAP) sensor,

and automatic transmission control systems . In older

vehicles, vacuum is also supplied to the distributor

vacuum advance or retard mechanism . These

devices can be connected directly to manifold

vacuum, or can be controlled through electric

solenoids, thermostatic switches, or other

vacuum controls .

TROUBLESHOOTING THE VACUUM SYSTEM

Most vacuum problems can be traced to leaks, which

occur in hoses, connectors, motor diaphragms or

valves . Pinched lines or clogged valves will also not

allow vacuum flow . Problems can also be traced to

improper mechanical operation of devices driven by

vacuum motors .

The vacuum pump can be used to measure the

amount of vacuum in a hose . The vacuum gauge

feature is very useful for detecting a fluctuating

vacuum supply or a leaky hose . The vacuum pump

feature enables you to check all types of vacuum

operated devices .

On a vacuum motor, for example, the pump is used

to evacuate the diaphragm chamber, which allows

you to check the mechanical operation of the device

as well as the amount of vacuum required to

actuate it . Test for a leaking diaphragm by applying

10” Hg vacuum to the device (FIGURE 4) . Observe

the gauge to see if the needle drops after the

actuator stops moving . If the needle continues

to drop, a leaking diaphragm is indicated . If the

diaphragm is okay, the vacuum should hold for

one minute with the needle steady .

the automotive vacuum sYstem

FIGURE 3: TYPICAL VACUUM DISTRIBUTION SYSTEM

To Intake Manifold

To A/C

Heater

PRNDL Switch

Brake

Release Motor

Distributor

Advance

Power Brake

Booster

Intake Air Motor

To Speed

Control

Auto

Trans

VACUUM DISTRIBUTION BLOCK

Page Number - 6

Form 8433