Turbocharger wastegate – Mityvac MV8500 silverline elite aUtoMotive test kit User Manual

Page 12

Page Number - 1

Form 8433

SYSTEM OPERATION

The turbocharger wastegate (exhaust bypass valve)

limits the amount of boost (intake manifold pres-

sure) created by the turbo . When intake manifold

pressure becomes too high, the wastegate opens

to allow some exhaust to bypass the turbo . This

reduces the turbo boost .

Most turbo wastegate actuators operate using a

mechanical spring and diaphragm design . Under

normal operating conditions, the spring holds the

wastegate valve closed, and all exhaust is directed

to the turbocharger . A small tube connects the

wastegate actuator to the intake manifold or turbo

air outlet . When boost pressure becomes too high, it

pushes against the diaphragm until it overcomes the

spring force, causing the wastegate to open .

Testing the function of the wastegate and wastegate

actuator involves attaching the Mityvac hand pump

to wastegate and applying pressure .

SERVICE PROCEDURES

Follow the procedures below to diagnose a turbo- or

super-charger wastegate and actuator:

Cold Test for Visual Movement

1) Locate the wastegate actuator, and inspect it for

damage . Check the pressure hose for visible leaks

or cracks . Replace if necessary .

) Disconnect the pressure hose from the wastegate

actuator and connect the Mityvac hand pump in its

place .

3) Use the pump to apply pressure according to the

manufacturer’s specification .

4) Watch for the control rod to move and then hold

its position .

5) If the rod doesn’t move or hold its position, or if

the pressure leaks down as indicated by the gauge

on the hand pump, replace or repair the wastegate

actuator .

6) If no leak is found, disconnect the actuator rod

and move the wastegate flapper lever to determine

if it is stuck or seized .

7) If it does not move freely, the wastegate should

be replaced or repaired .

Idle Test

8) Start with the exhaust system cold .

9) Disconnect the pressure hose from the wastegate

actuator and connect the Mityvac hand pump in its

place .

10) Start the engine and allow it to idle .

11) After a short time, the exhaust inlet to the wa-

stegate should warm up, but the bypass line out of

the wastegate should remain cool .

1) If the bypass line heats up at this point, exhaust

is leaking past the wastegate, and the wastegate

should be replaced or repaired .

13) Use the pump to apply pressure to open the

wastegate according to the manufacturer’s specifica-

tion .

14) Feel the bypass line . It should begin to warm up

as the wastegate opens .

15) If not, the wastegate is stuck closed and should

be replaced or repaired .

16) Once testing is complete, bleed the pressure

from the pump and watch for the wastegate to

close .

Bench Testing

A Mityvac hand pump should be used to bench test-

ing the turbocharger wastegate, and adjusting the

control arm after replacement or repair . Follow the

manufacturer’s procedures for performing these

precision tests and adjustments .

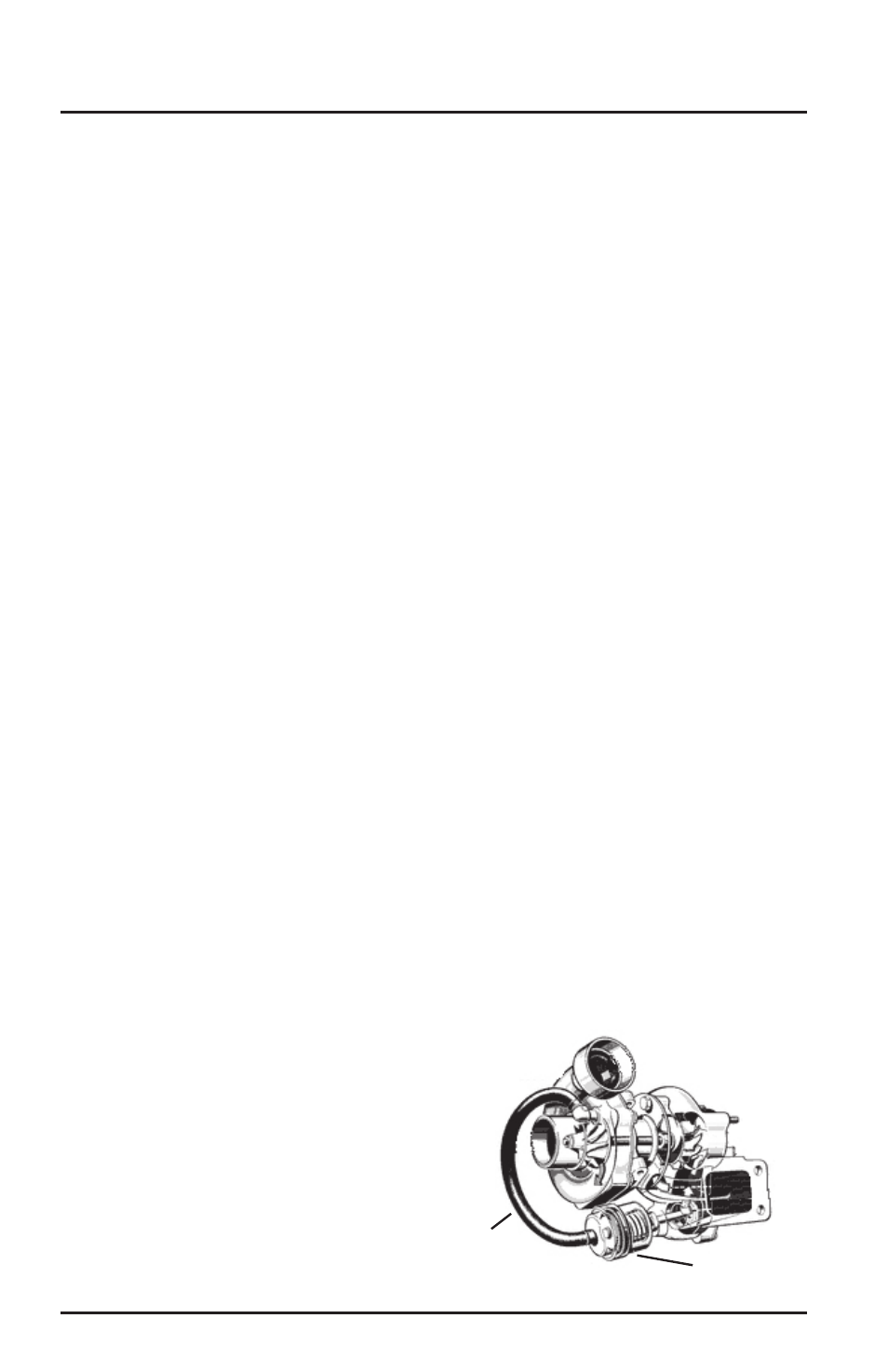

turbocharGer wasteGate

FIGURE 7: TURBOCHARGER

Pressure

Connection

Wastegate Actuator