Fuel pressure regulator – Mityvac MV8500 silverline elite aUtoMotive test kit User Manual

Page 10

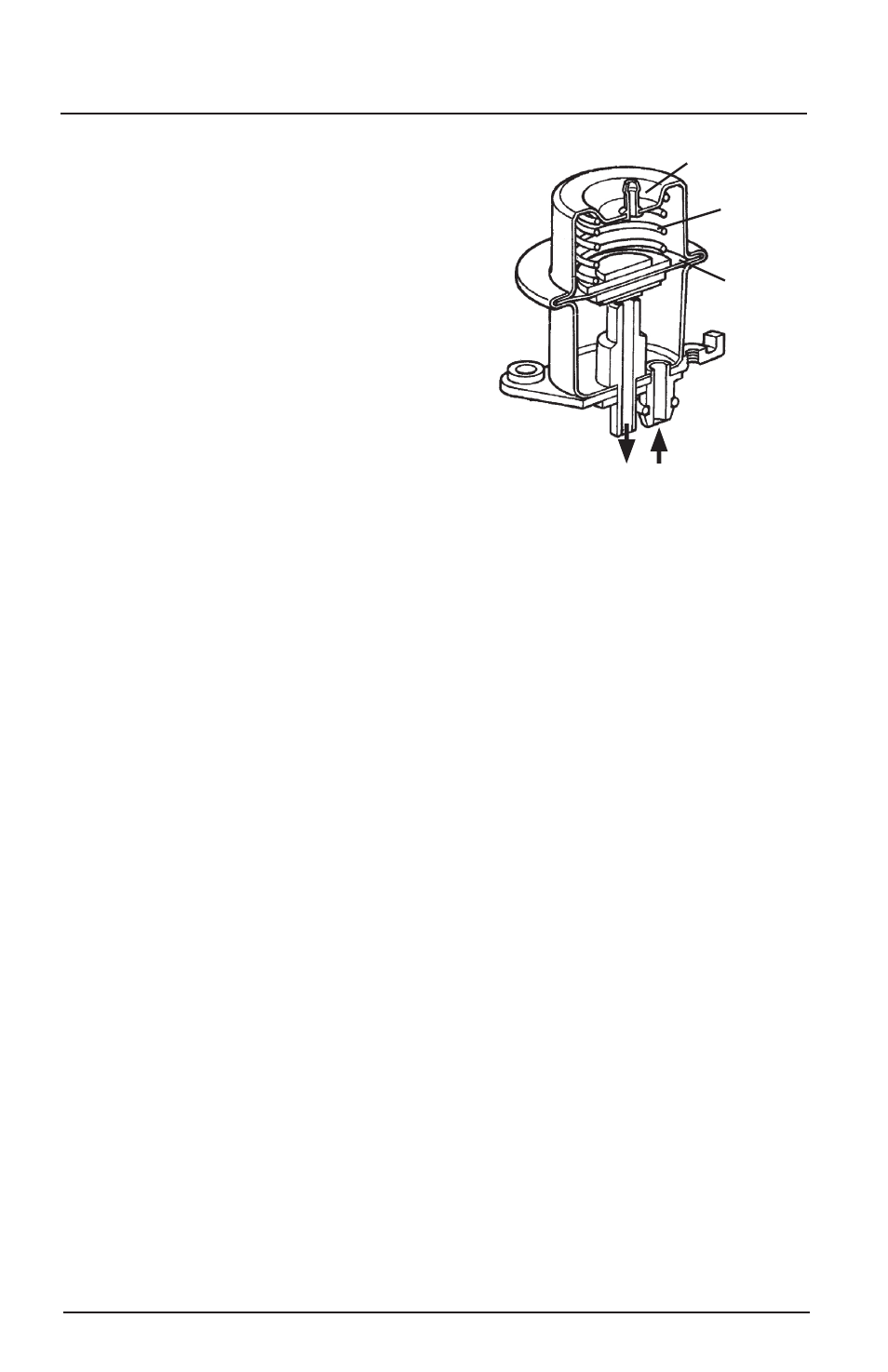

fueL pressure reGuLator

SYSTEM OPERATION

Fuel pressure regulators are used to maintain

fuel pressure at a steady level, consistent with the

requirements of the engine . Automotive manufac-

turers employ different methods for controlling

fuel pressure . Most utilize a mechanical spring and

diaphragm style pressure regulator such as the one

shown in figure 6 . Mechanical regulators most often

utilize engine vacuum and/or pressure to vary fuel

pressure in response to immediate engine require-

ments . A vacuum or vacuum/pressure pump with

appropriate gauge is required to properly diagnose

these types of regulators .

Vacuum/pressure controlled fuel pressure regula-

tors are commonly mounted on or immediately

after the fuel rail, and inline with the flow of fuel .

When the fuel pump is not operating, the spring

causes the diaphragm to close so that no fuel can

pass . Once the fuel pump is activated, the pressure

it produces begins to overcome the spring force

and the diaphragm opens to allow fuel to flow . The

spring and diaphragm maintain a constant pressure

on the flow of fuel . This creates back-pressure in the

fuel system, which is commonly referred to as “fuel

pressure” . The job of the fuel pressure regulator is

to maintain the “fuel pressure” at a level specified

by the vehicle manufacturer .

A vacuum/pressure-modulated fuel pressure regu-

lator is connected to the intake manifold by a small

hose . Vacuum from the manifold assists the spring

in opening the diaphragm . When a load is placed

on the powertrain, engine vacuum drops . This drop

in vacuum causes the diaphragm to increase the

resistance to fuel flow . The additional resistance

increases the fuel pressure to the injectors to com-

pensate for the higher fuel demand of the engine .

On forced-air induction systems (turbochargers/

superchargers), the boost pressure created in the

manifold functions the opposite of the vacuum pro-

duced in normally aspirated systems . Under boost

conditions, the pressure in the manifold causes the

regulator to increase fuel pressure, resulting in a

richer fuel mixture .

SERVICE PROCEDURES

Visual Inspection

1) Consult the vehicle’s service manual to determine

if the pressure regulator is vacuum/pressure modu-

lated, and to identify its location .

) Inspect the exterior of the pressure regulator for

fuel leaks, and the vacuum hose for visible damage

or cracks . Replace if necessary .

3) Disconnect the vacuum hose from the fuel pres-

sure regulator .

4) Check inside the hose for liquid fuel . If present,

replace the regulator . If not present, reconnect the

vacuum hose .

Diagnostics

5) Install a fuel pressure tester .

6) Start the engine and allow it to idle .

7) Disconnect the vacuum line from the fuel pres-

sure regulator .

8) Fuel pressure should increase 8 to 1 psi when

the line is disconnected . No change would indicate a

faulty regulator, or leaky or plugged vacuum line .

9) Connect the vacuum pump to the vacuum hose

extending from the manifold .

FIGURE 6:

PRESSURE

REGULATOR

Vacuum/Pressure

Connection

Spring

Diaphragm

Fuel In

Fuel Out

Page Number - 10

Form 8433