Spark delay valves (sdv) – Mityvac MV8500 silverline elite aUtoMotive test kit User Manual

Page 17

Form 8433

Page Number - 17

OPERATION

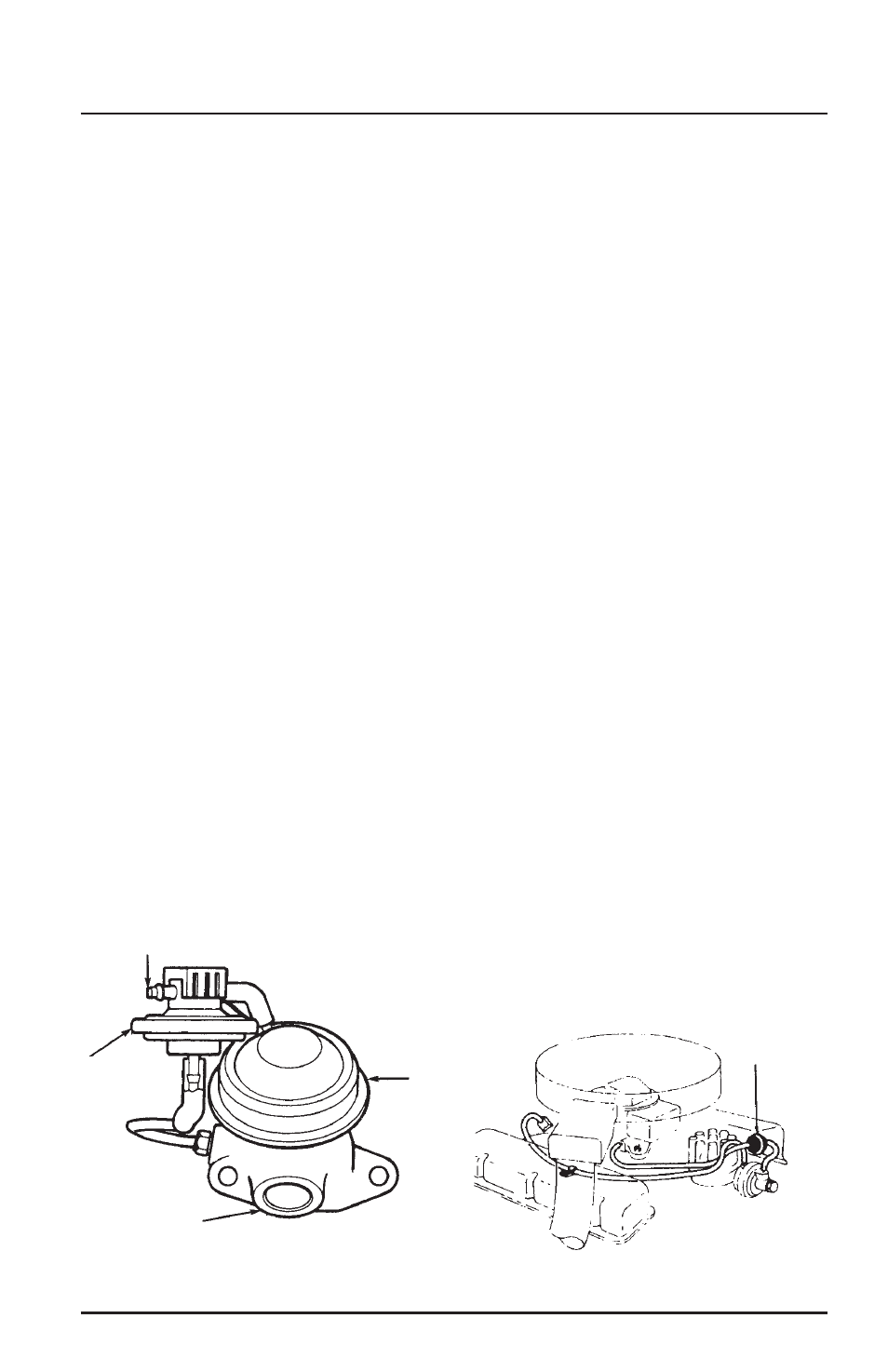

Spark Delay Valves (SDV) are used to delay vacuum

to the distributor vacuum advance actuator during

hard acceleration, to delay the action of the

Thermactor Air Induction Reaction (AIR) system

during prolonged engine idling, and to delay the

application of vacuum to the automatic choke

pulldown diaphragm during cold engine operation .

A sintered metal valve is installed in the vacuum

advance (outer) diaphragm of the distributor con-

trol unit on some engines . The purpose of the valve

is to delay the spark advance during rapid accelera-

tion to minimize the formation of NOx . The sintered

metal is porous and allows vacuum to bleed through

the valve acting like an orifice of about 0 .00” in

diameter . Control is obtained by varying the num-

ber of discs in each valve assembly so that the time

delay features can be tailored to the engine

(FIGURE 13) .

SERVICE PROCEDURES

The time delay of the valve varies with engine

application . The different valves may be identified

by color and part number . Spark delay valves can-

not be repaired and must be replaced every 1,000

miles because the pores of the sintered metal fill

with dust, which can slow the performance of the

valve . NOTE: The spark delay valve is a one-way unit

that must be installed with the Black side facing the

carburetor vacuum port .

To determine if a spark delay valve is operating

correctly, the following service procedure should

be used:

1) With the transmission in neutral, set the carburetor

to the fast-idle position, remove the spark-delay valve

and tee your vacuum pump into the hose leading to

the carburetor spark port .

) Record the vacuum reading, which should be

between 10 to 16” Hg .

3) Pinch off the vacuum hose and observe if the

gauge maintains the vacuum level . If the gauge

shows that the vacuum drops with the hose pinched

off, the gauge or vacuum hose has an external

leak, which must be corrected .

4) Now, connect the black side of the spark-delay

valve to the vacuum hose leading to the carburetor

spark port . Connect a section of vacuum hose to

your vacuum pump and attach the other end to the

distributor end of the spark delay valve . Observe

the time in seconds for the gauge to reach 6” Hg,

with a 10 to 16” Hg vacuum source . If the vacuum

reaches the 6” Hg level in less than two seconds,

regardless of type, the SDV should be replaced .

When checking the valve, care must be taken to

prevent oil or dirt from getting into the valve as

this will impair its function .

Attach the Pump Here

Transducer

Exhaust Gas Inlet

ERG

Valve

FIGURE 13: TYPICAL SPARK DELAY VALVE

Spark

Delay

Valve

FIGURE 12: TEST THE VACUUM SOURCE FOR

THE BPV WITH YOUR PUMP

sparK DeLaY vaLves (sDv)