Exhaust gas recirculation (egr) – Mityvac MV8500 silverline elite aUtoMotive test kit User Manual

Page 16

EGR VENTURI VACUUM AMPLIFIER

Some engines utilize a Venturi Vacuum Amplifier

that uses the weak vacuum signal from the throat of

the carburetor to allow the passage of the stronger

intake manifold vacuum to operate the EGR valve .

On most applications the amplifier provides a ” Hg

boost to the Venturi signal (FIGURE 10) .

SERVICE PROCEDURES

1) Start the engine, and run it at idle until it reaches

normal operating temperature .

) Make sure the intake manifold hose to the

amplifier is properly connected . On those systems

with a reservoir, remove the hose from the reser-

voir and use a tee connector to join the hose to the

intake manifold vacuum hose .

3) With separate lengths of hose and different

connectors, bypass any and all vacuum valves or

coolant controlled valves between the amplifier

and the EGR valve .

4) Use a tee connector to attach the pump into the

vacuum line between the amplifier and EGR valve .

5) Increase engine speed to 1500 to 000 RPM

and release the throttle . Let the engine return to

idle speed and remove the vacuum hose at the

carburetor venturi . The vacuum reading should be

within ± 0 .3” Hg of the specified boost for that

amplifier if other than zero boost is specified .

Zero boost may read from 0 to .5” Hg . Replace

amplifier if it is out of specification .

6) Increase engine speed . Watching the vacuum

gauge, release the accelerator after a speed of

1500 to 000 RPM is reached . If the vacuum gauge

reading shows an increase greater than 1” Hg

during acceleration period, the amplifier should

be replaced .

7) Remove the pump from the output vacuum

line and reconnect the hoses, but still bypass other

valves . Connect the pump and apply to 4” Hg of

vacuum to port on the amplifier which is normally

connected to intake manifold vacuum . The EGR

valve should operate and engine idle should drop or

become erratic . If the EGR valve fails to move,

replace the amplifier .

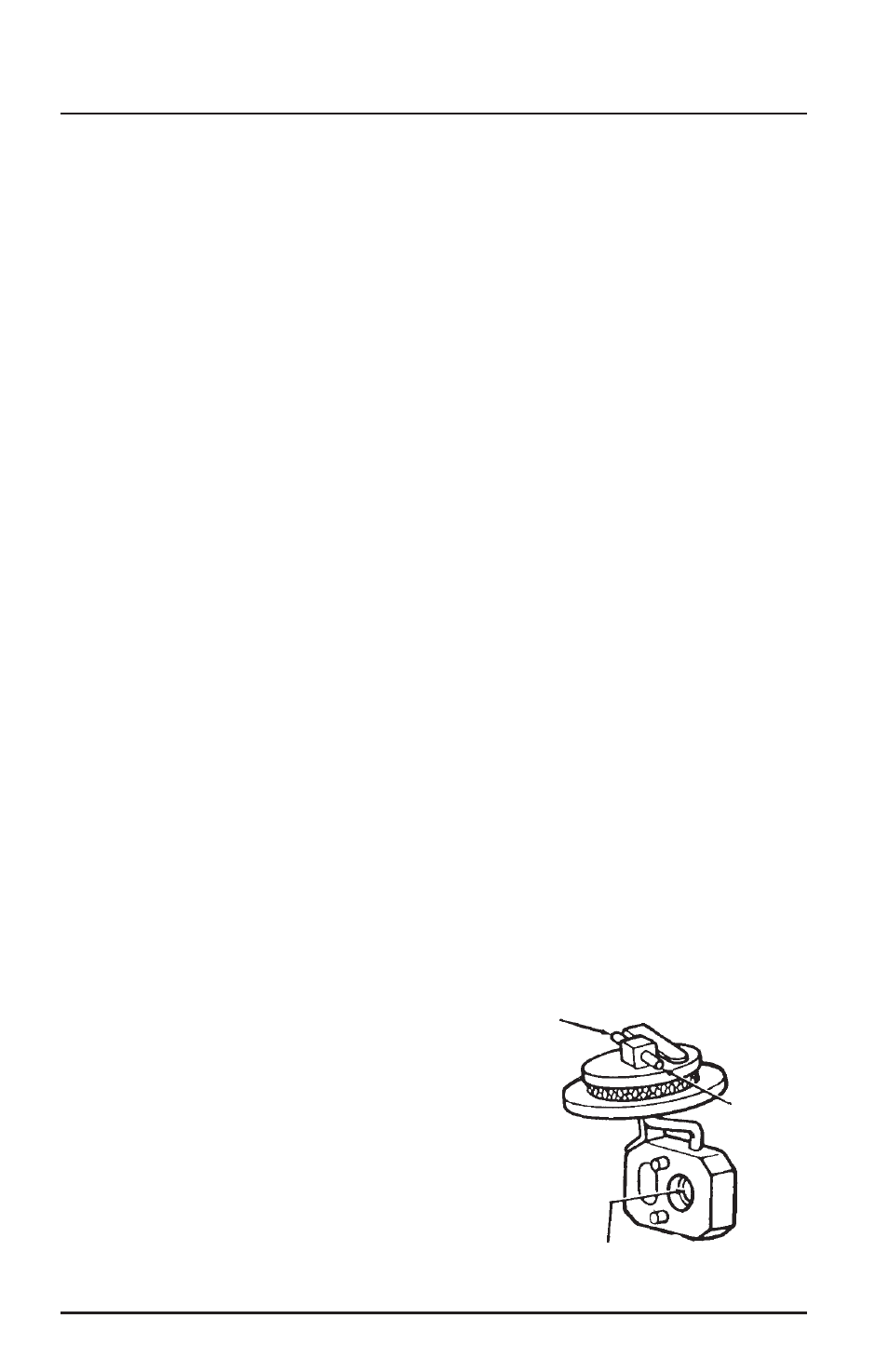

BACK-PRESSURE TRANSDUCER VALVE

(BPV) OPERATION

The Back-pressure Transducer Valve (BPV) controls

the amount of EGR according to the load on the

engine . An exhaust pressure probe extends into

the exhaust crossover passageway to sample the

exhaust gas pressure . During light engine loads,

the pressure in the exhaust passageway is relatively

low, while during wide-open throttle operation

(WOT), the pressure is highest . This pressure signal

is transmitted to a diaphragm in the BPV and is used

to control the amount of vacuum applied to the EGR

valve (FIGURE 11) .

SERVICE PROCEDURES

1) Remove the air cleaner and plug the intake

manifold fitting . Start the engine and bring it to

normal operating temperature . Position the fast-idle

cam follower on the second step of the fast-idle cam

(to obtain about 1500 RPM), and then note engine

speed on a tachometer . Use the pump to check the

source vacuum at an intake manifold port (FIGURE

1) . Note this reading .

) Tee your pump into the vacuum passageway to

the BPV and the reading should be 1 to ” Hg of

vacuum . Replace the BPV if it is not within specifica-

tions .

3) Leave the vacuum gauge at this location, remove

the hose to the EGR valve, and plug the hose open-

ing . Read the vacuum pump gauge, which should be

the same as the intake manifold vacuum reading . If

it is not within ” Hg of the source vacuum, replace

the BPV valve .

eXhaust Gas recircuLation (eGr)

FIGURE 11:

EXHAUST BACKPRESSURE TRANSDUCER VALVE

To Distributor

Spark–

EGR Thermal

Vacuum Valve

Exposed to Exhaust Gas Pressure

To EGR

Valve

Page Number - 16

Form 8433