Mallory Ignition Mallory HYFIRE 6A and 6AL SERIES ELECTRONIC IGNITION CONTROLS 6852M_6853M User Manual

Page 2

MALLORY IGNITION

www.malloryperformance.com

2

area, such as the glovebox. When you find a suitable

location to mount the unit, make sure all wires of the ignition

reach their connections. Hold the ignition in place and mark the

location of the mounting holes. Use a 1/8" drill bit to drill the

holes. Use the supplied self-tapping screws to mount the box.

WIRING

Wire Length

All of the wires of the HYFIRE

®

6A Ignition Control may be

shortened as long as quality connectors are used or soldered

in place. To lengthen the wires, use one size larger gauge wire

(12 gauge for power leads, 16 gauge for all others). Use the

proper connectors to terminate all wires. All connections must

be soldered and sealed.

Grounds

A poor ground connection can cause many frustrating problems.

When a wire is specified to go to ground, connect it to the

chassis. Always connect a ground strap between the engine and

chassis. Connect any ground wires to a clean, paint-free metal

surface.

Ballast Resistor

If your vehicle has a ballast resistor in line with the coil wiring, it

is not necessary to bypass it. This is because the HYFIRE

®

6A

Ignition Control receives its main power directly from the battery.

MISCELLANEOUS INFORMATION

Sealing

Do not attempt to seal the HYFIRE

®

6A Ignition Control. All of the

circuits of a HYFIRE

®

6A receive a conformal coating of sealant

that protects the electronics from moisture. Sealing the HYFIRE

®

6A will not allow any moisture that seeps in through the

grommets to drain and may result in corrosion.

Welding

To avoid any damage to the HYFIRE

®

6A Ignition Control when

welding on the vehicle, disconnect the positive (red) and negative

(black) power cables of the HYFIRE

®

6A Ignition Control. It is also a

good idea to disconnect the tachometer ground wire as well.

Distributor Cap and Rotor

We recommend installing a new distributor cap and rotor when

installing the HYFIRE

®

6A Ignition Control. Be sure the cap is clean

inside and out, especially the terminals and rotor tip. On vehicles

with smaller caps, it is possible for the air inside the cap to become

electrically charged causing crossfire which can result in misfire.

You can prevent this by drilling a couple of vent holes in the cap.

Drill the holes between terminals at rotor height, facing away from

the intake. If needed, place a small piece of screen over the holes

to act as a filter.

HYFIRE

®

6A Diagnostic LED

On the end panel of your Hyfire 6A ignition there is a small hole.

Behind this hole is a red LED indicator. This serves two purposes:

when you first turn on the ignition switch, the LED will flash

rapidly 3 times. This indicates that the ignition system has power,

and that the microprocessor is running properly. In addition, the

LED will flash when receiving a proper trigger signal from the

vehicle. If, after a normal power-up, the LED doesn’t flash when

cranking the engine, you should check your triggering circuit for

problems. If the LED flashes when the

engine is cranked, but there is still no

spark, the problem lies somewhere else.

HYFIRE

®

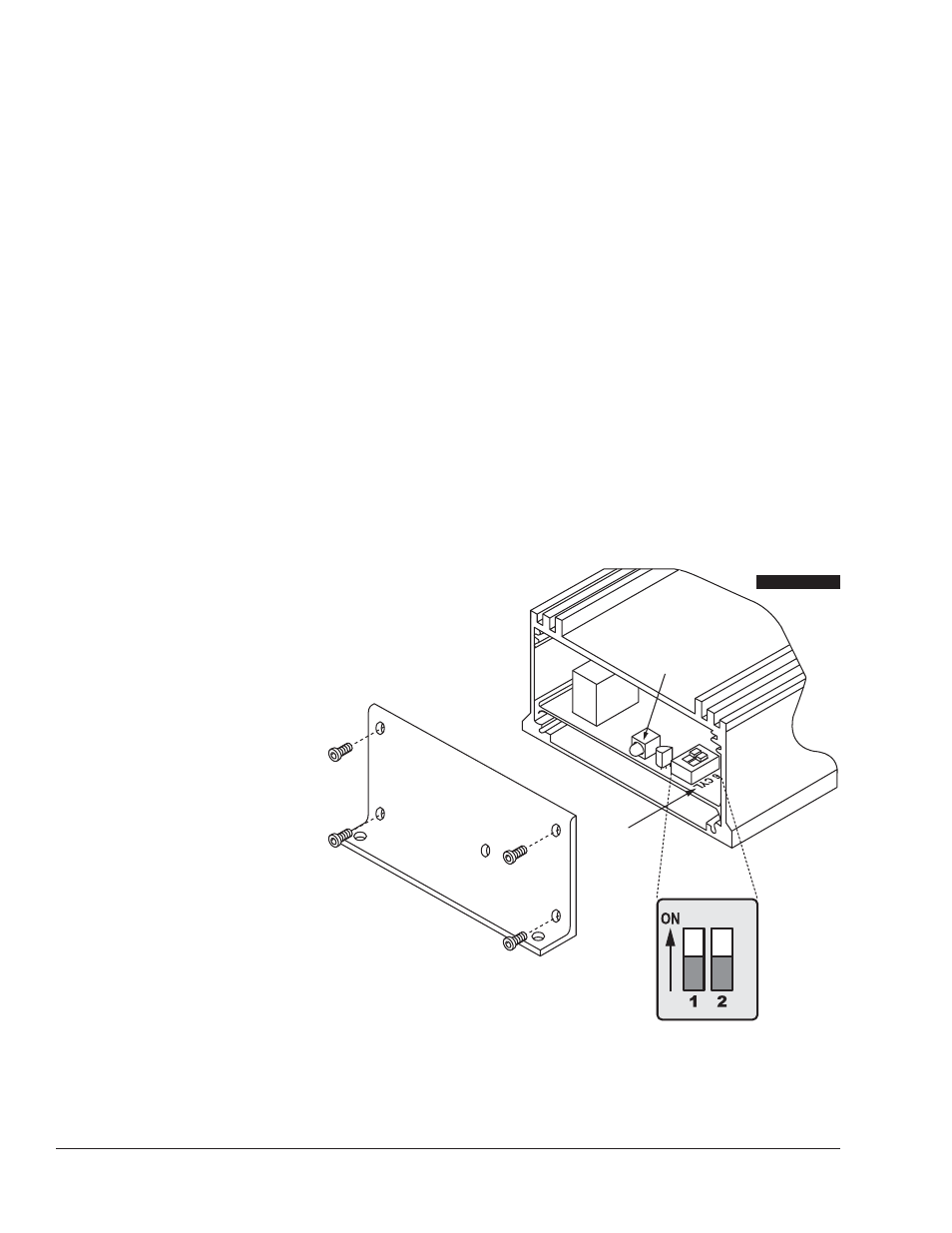

6A Cylinder Selection

Your HYFIRE

®

6A Ignition comes from the

factory set up for 8 cylinder operation. If

you want to use this ignition with a 4 or 6

cylinder engine, you must first remove the

four screws that hold the endplate with the

LED hole. Once the endplate is removed,

you’ll see the end of the circuit board. Look

for the two-section switch. To select 4 cylinder

mode, move the switch marked “1” to the “ON”

position. To select 6 cylinder mode, move the switch

marked “2” to the “ON” position. If both switches are “OFF”,

or both are “ON”, the ignition will run in the 8 cylinder mode.

See Figure 1.

MOUNTING

The HYFIRE

®

6A Ignition Control can be mounted in any position. If

you mount it in the engine compartment, keep it away from mov-

ing objects and heat sources. Do not mount the unit in a closed

LABELS FOR

"CYLINDER SELECT"

ON CIRCUIT BOARD

DIAGNOSTIC

LED

FIGURE 1