Acquisition problems, Verification problems – Luminex FLEXMAP 3D Hardware User Manual User Manual

Page 54

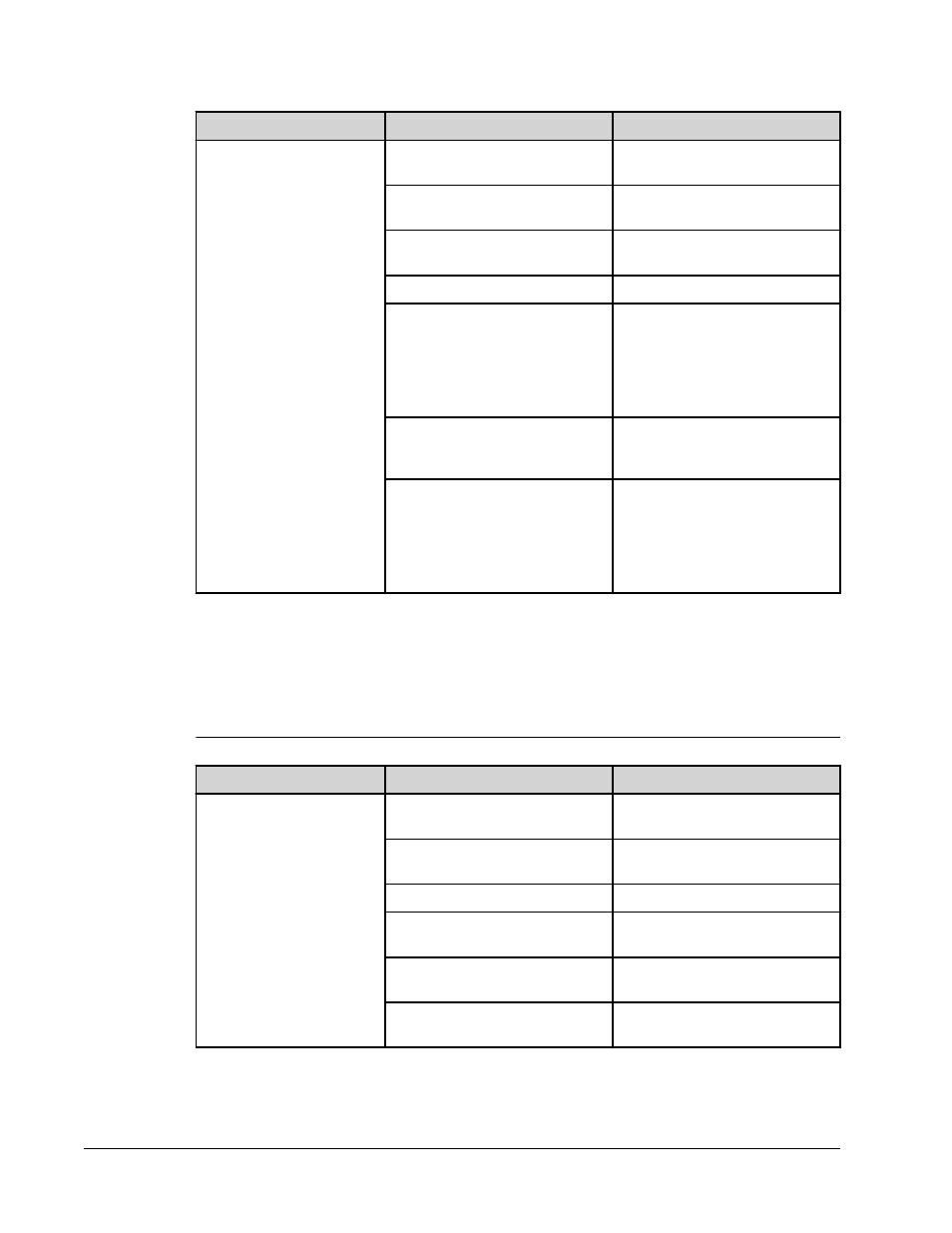

Symptom

Possible cause

Solution

The verification lot is expired.

Use an unexpired bottle of

verification microspheres.

The verification microspheres

have been diluted.

Do not dilute the verification

microspheres.

The sample probe height is

incorrect.

Perform an automatic sample

probe height adjustment.

The sample probe is clogged.

”.

There is air in the instrument.

Verify the sample probe height.

Use the software to run a prime

command three times, an alcohol

flush command twice, then a wash

command three times with distilled

water.

The waste line was moved during

instrument operation, resulting in

an unstable flow rate.

Stabilize the waste line during

instrument operation. See the

section titled “

”.

There is a problem internal to the

instrument.

Review the log of calibration

reports. Check for dramatic

changes in temperature, sheath

pressure, or voltage. If any of

these are present, contact

Technical Support.

Acquisition Problems

TABLE 8.

Verification Problems

Symptom

Possible cause

Solution

Acquisition fails or is slow.

The air pressure is out of range.

See the section titled

“

”.

The sample probe height is

incorrect.

Perform an automatic sample

probe height adjustment.

The sample probe is clogged.

”.

The sheath or waste lines are not

fully connected.

Disconnect and reconnect the

lines; you should hear them click.

The calibration microspheres have

expired.

Replace old microspheres with an

unexpired lot.

The wrong wells are selected for

the calibration microspheres.

Ensure that the correct wells are

selected in the software.

Troubleshooting

43