Clogs, Pressurization problems, Clogs pressurization problems – Luminex FLEXMAP 3D Hardware User Manual User Manual

Page 50

Clogs

Often, a clog somewhere in the Luminex

®

FLEXMAP 3D

®

instrument is the cause of a fluid

leak, a pressurization or sample probe problem, or a problem with calibration, verification, or

data acquisition.

To determine whether there is a clog, check the bead count during calibration. During

calibration you should see 300 bead events per second or more. If there are fewer than that,

there is probably a clog in the instrument.

In the event you encounter a problem that is clog-related, use the following procedure.

To troubleshoot a possible clog:

1. Clean and adjust the sample probe. See the section titled “

2. Perform the procedure for removing clogs. See the section titled “

”.

3. Replace all fluids.

4. Use the software to run the weekly maintenance routine.

5. Run calibration and verification.

If this procedure is unsuccessful, call Luminex Technical Support.

Pressurization Problems

Normal air and sheath pressure readings vary between 8 and 13 psi while the compressor

runs. If the instrument pressure is out of range, sample acquisition either can fail or can

return inadequate results.

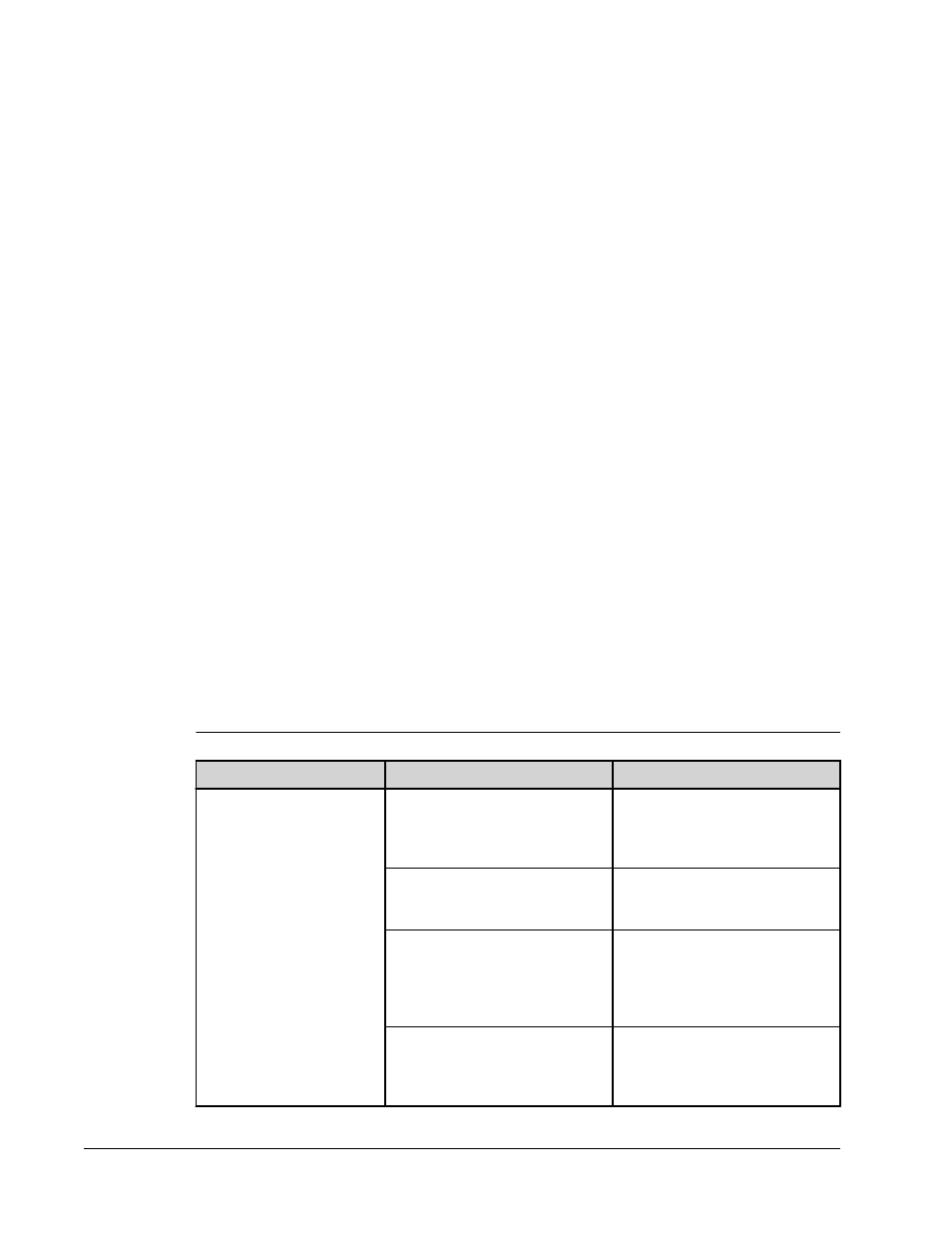

TABLE 3.

Pressurization Problems

Symptom

Possible cause

Solution

Pressurization fails or

pressure is too low.

The sheath and waste lines are

not fully connected.

Check the lines between the

sheath and waste bottles and the

Luminex FLEXMAP 3D

instrument.

The sheath or waste fittings are

cracked.

Inspect the fittings to be sure they

form a tight seal. If not, call

Technical Support.

There is a leak in the instrument.

Check for leaks. A leak is obvious

if there is fluid on the surface

where the FLEXMAP 3D

instrument sits. See the section

titled “

”.

The compressor does not engage. Use the software to run a prime

command. If you do not hear the

compressor turn on, contact

Technical Support.

Troubleshooting

39