Lap pad operation, Lap pad overview – Liquid Controls LCR-II Setup & Operation User Manual

Page 6

6

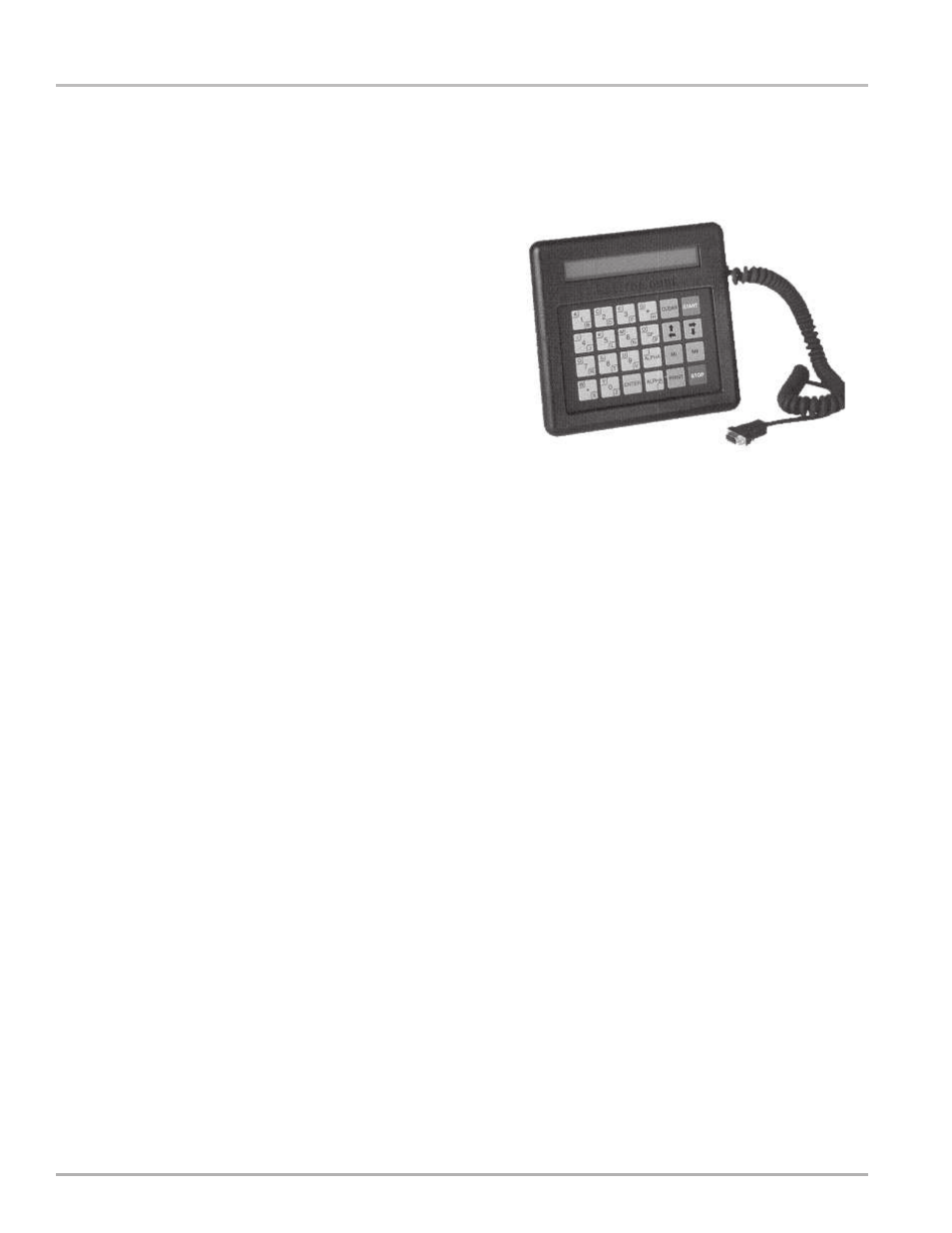

Lap Pad Operation

This section of the manual provides instructions for the

initial set-up, calibration and operation of your LCR-II

Electronic Register using the Liquid Controls Lap Pad

data entry device. This section should first be scanned

to become familiar with the components of the system,

the layout and format of the document, the basic menu

(screens) and data entry required. This section should

then be carefully followed as the system is being set up

and calibrated. (Refer to the Installation Manual for

instructions on connecting the Lap Pad for use with the

LCR-II).

Following is a brief overview of the top level Program

Menu screens.

DELIVERY & PRESET

This menu includes up to seven data screens for setting preset quantities, product prices, taxes and

other relevant delivery information.

PRODUCT & SHIFT INFORMATION

This menu includes four secondary data screens for viewing product types and basic parameters

pertaining to shift information.

GENERAL SET-UP

This menu includes five secondary data screens for setting the internal clock and calendar, initializing

sale and ticket number counters, setting the no-flow timer and defining data to be printed on tickets.

SYSTEM CALIBRATION

This menu includes five secondary screens for entering Meter ID, printer selections, units of measure,

rounding and truncating.

PRODUCT CALIBRATION

This menu includes eight secondary screens for assigning unique codes to products; defining product

types such as gasoline, diesel fuel, LPG, etc.; and compensation parameters such as base temperature

for temperature compensated deliveries.

DIAGNOSTICS

This menu includes four secondary screens for viewing system parameters such as software version,

supply voltage, and pulser diagnostic information.

SECURITY

This menu includes one secondary screen for user password and system security.

LAP PAD OVERVIEW