Periodic service, Troubleshooting guide, Introduction – Controlled Products Systems Group PAT1AC User Manual

Page 28

26

Periodic Service

All gate operators require periodic checking and adjustments, by a qualified technician of the control

mechanism for force (load), speed and sensitivity. All external accessories and secondary safety

devices must be checked. Secondary safety devices need to be checked at least once a month for

proper operation.

Periodic checking is also advised for the following:

1. Check battery connections and verify terminals are clean. Maintenance free batteries recommended.

2. Hinges and pivot points need to be greased. Apply grease to actuator stainless tube as needed.

3. Bolts for correct tightness.

4. Inspect weld points for cracks or other defects.

5. Inspect wiring for cuts, nicks or other defects.

6. Inspect hinge post to ensure it is not moving or twisting.

7. If AC charger is used verify proper charger operation. Refer to charger instructions.

8. Verify that the inside of the control cabinet remains clean and free of insects. Do not spray control

board with bug spray.

Troubleshooting Guide

Introduction

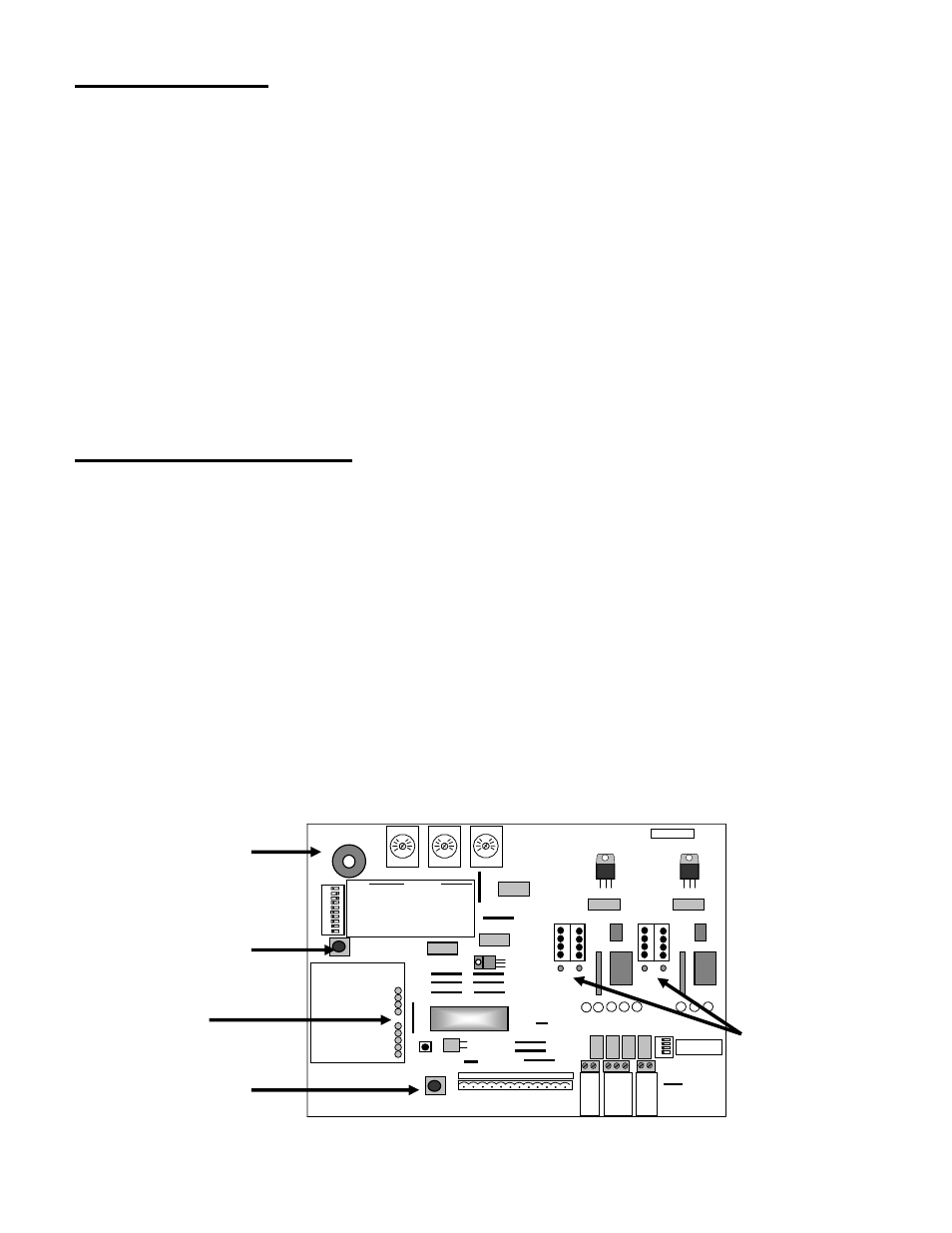

The Patriot control board is equipped with three unique features to assist in troubleshooting a gate system.

1.

The first and most helpful is the series of LED indicating lights. These lights will help to identify problems

with the actuator limit switches and all control circuits. To use the indicators, press and hold the “LED

Indicator” button on the control board. (The LED’s are not active unless the LED indicator push button is

pressed and held to save battery life). Any circuits or limit switches that are activated will be obvious by

the illumination of the adjacent LED.

2.

The second feature to assist in troubleshooting is the current sense beeper. The beeper will sound

anytime the current sense circuit is activated. This is useful in detecting a false reverse due to an

improper or too sensitive current reverse setting, or a gate which is requiring excessive force to move.

3.

The third feature to assist in troubleshooting is the on board “Open / Close Command” pushbutton. This

button makes it possible to operate the gate with the twelve terminal wiring plug removed, without

having to short across terminal pins.

Siren Output

OPEN/CLOSE

COMMAND

Vehicular Gate Operator

Gate Weight Max. Load: 650 lbs.

LED INDICATOR

S2

RESET

Entrapment

S

E

C

U

R

I

T

Y

S

H

U

N

T

C

O

M

M

O

N

G

N

D

M

A

G

L

O

C

K

S

O

L

O

N

O

I

D

L

O

C

K

C

O

M

M

O

N

G

N

D

O

U

T

P

U

T

+

1

2

V

O

N

2

3

4

1

SOLONOID LOCK ENABLE

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

15

5

0

10

TIMER TO CLOSE

ADJUSTMENT

Timer

ADJUSTMENT

Class I or Class II per UL325

J2

INDICATORS

1-

+12V OUT 1.5 AMP MAX

2- COMMON

GROUND

3-

PUSH BUTTON INPUT

4-

OPEN SAFETY EDGE

5- CLOSE

INPUT

6-

SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON

GROUND

8-

STOP CIRCUIT INPUT N/C

9-

FREE EXIT / OPEN INPUT

10-

UNDER GATE / CENTER LOOP INPUT

11-

SAFETY LOOP / REVERSING EDGE INPUT

12-

MOTION DETECTOR INPUT

1

2

3

4

5

6

7

8

9 10 11 12

J2

BOTH ON FOR DUAL

DS1 SWITCH SETTINGS

FACTORY SETTINGS

SW-1

AUTO CLOSE TIMER ENABLE

OFF

SW-2

TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY

ON

SW-3

MASTER GATE ENABLE

ON

SW-4

SLAVE GATE ENABLE

OFF

SW-5

SOLENOID LOCK OPTION, SEE INSTALLATION MANUAL

OFF

SW-6

SOFT STOP RETRACT ENABLE

OFF

SW-7

SOFT STOP EXTEND ENABLE

OFF

SW-8

STOP CIRCUIT ENABLE

OFF

SW-9

OPERATING DIRECTION REVERSE

OFF

SW-10

SOFT START ENABLE FOR SW6 AND SW7

OFF

1

2

3

4

5

6

7

8

9

10

O

N

DS1

PATRIOT CONTROL BOARD

USAutomatic

MADE IN USA

CURRENT SENSE

ADJUSTMENT

0

10

5

MASTER

Sensitivity

CURRENT SENSE

ADJUSTMENT

0

10

5

SLAVE

Sensitivity

15

Current sense beeper

LED Indicator Button

LED Indicators

LED Indicators

Open/Close Command

pushbutton