Step 9 connecting actuator cable to control board, Step 10 current sense adjustment, Figure 15 reset button – Controlled Products Systems Group PAT1AC User Manual

Page 14: Current sense adjustments master and slave

12

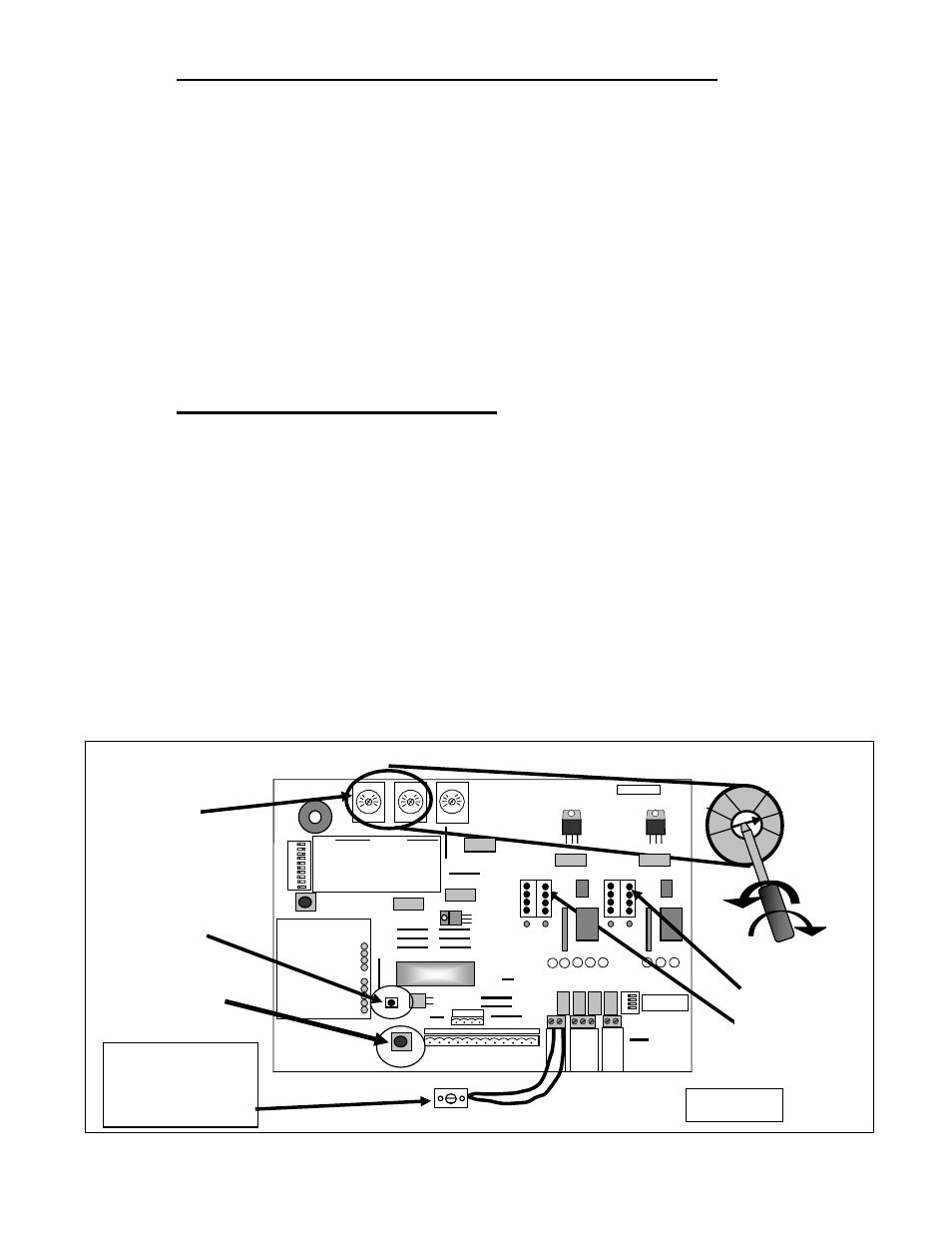

STEP 9 Connecting Actuator Cable to Control Board

Before connecting the actuator cable to the control board check the following:

Verify that all previous steps were performed.

Verify that the battery connections are correct, red leads to positive and black leads to negative.

Verify that nothing is in the path of the gate, if by chance it begins to move when power is applied.

Be prepared to disconnect the actuator cable, if needed to stop the gate if it begins to move.

Patriot I

Locate the master actuator cable and plug it into the “Master” actuator connector (see figure 15) on the

control board. You might here a beep from the control board when power is supplied. This is not a problem.

Patriot II

Locate the master actuator cable and plug it into the “Master” actuator connector (see figure 15) on the

control board. You might here a beep from the control board when power is supplied. This is not a problem.

Locate the slave actuator cable and plug it into the “Slave” actuator connector (see figure 15).

STEP 10 Current Sense Adjustment

The control board has two current sense adjustments, MASTER and SLAVE (see figure 15). On single gate

installations adjust both to the same setting, on dual gates adjust each one to the desired setting. Adjust

sensitivity so that the gate force required to sense an obstruction is at the desired level.

Remember if the gate reverses direction when operating without contacting an obstruction, then minimizing

sensitivity (increase force) may be required. Do not increase more than necessary.

The adjustment has a maximum rotation of 1 turn, beginning at 0 and ending at 10. The factory setting is

around number 3. Do not force the adjustment past the stop points.

IMPORTANT NOTE:

Locate the sensitivity adjustments in figure 15. Notice that there are two adjustments MASTER and SLAVE.

We intentionally set the sensors at a highly sensitive setting. This may need to be adjusted to achieve gate

movement without tripping the sensitivity circuit and causing the gate to reverse direction. If the gate

reverses direction twice and then stops the control board will need to be reset.

Open / Close

Command button

Secondary

Entrapment Siren

Red +12 vdc

Black Ground

10

0

5

Siren Output

OPEN/CLOSE

COMMAND

Vehicular Gate Operator

Gate Weight Max. Load: 650 lbs.

LED INDICATOR

S2

RESET

Entrapment

S

E

C

U

R

I

T

Y

S

H

U

N

T

C

O

M

M

O

N

G

N

D

M

A

G

L

O

C

K

S

O

L

O

N

O

I

D

L

O

C

K

C

O

M

M

O

N

G

N

D

O

U

T

P

U

T

+

1

2

V

O

N

2

3

4

1

SOLONOID LOCK ENABLE

MAGNETIC LOCK ENABLE

SECURITY SHUNT ENABLE

MOTION DETECTOR ENABLE

15

5

0

10

TIMER TO CLOSE

ADJUSTMENT

Timer

ADJUSTMENT

Class I or Class II per UL325

J2

INDICATORS

1-

+12V OUT 1.5 AMP MAX

2- COMMON

GROUND

3-

PUSH BUTTON INPUT

4-

OPEN SAFETY EDGE

5- CLOSE

INPUT

6-

SECONDARY ENTRAPMENT DEVICE INPUT

7- COMMON

GROUND

8-

STOP CIRCUIT INPUT N/C

9-

FREE EXIT / OPEN INPUT

10-

UNDER GATE / CENTER LOOP INPUT

11-

SAFETY LOOP / REVERSING EDGE INPUT

12-

MOTION DETECTOR INPUT

1

2

3

4

5

6

7

8

9 10 11 12

J2

BOTH ON FOR DUAL

DS1 SWITCH SETTINGS

FACTORY SETTINGS

SW-1

AUTO CLOSE TIMER ENABLE

OFF

SW-2

TIMER TO CLOSE WILL ACTIVATE ON LIMIT ONLY

ON

SW-3

MASTER GATE ENABLE

ON

SW-4

SLAVE GATE ENABLE

OFF

SW-5

SOLENOID LOCK OPTION, SEE INSTALLATION MANUAL

OFF

SW-6

SOFT STOP RETRACT ENABLE

OFF

SW-7

SOFT STOP EXTEND ENABLE

OFF

SW-8

STOP CIRCUIT ENABLE

OFF

SW-9

OPERATING DIRECTION REVERSE

OFF

SW-10

SOFT START ENABLE FOR SW6 AND SW7

OFF

1

2

3

4

5

6

7

8

9

10

O

N

DS1

PATRIOT CONTROL BOARD

USAutomatic

MADE IN USA

CURRENT SENSE

ADJUSTMENT

0

10

5

MASTER

Sensitivity

CURRENT SENSE

ADJUSTMENT

0

10

5

SLAVE

Sensitivity

15

Master actuator

connector.

Slave actuator

connector.

Figure 15

Reset button

Current sense

adjustments

master and

slave

J5

1 2 3 4