2 diagnostics check continued, 3 troubleshooting – Controlled Products Systems Group 4302-111 User Manual

Page 28

4302-065-F-1-13

26

3.2 Diagnostics Check Continued

4. Check that there are no shorted or open control wires from the keying devices to the gate operator. If a keying device fails

to open the gate, momentarily jumper across terminals 1 and 2 on the control board. If the gate operator starts, this indicates

that a problem exist with the keying device and not with the gate operator.

5. Check the supply voltage and batteries. A voltage drop on the supply line (usually caused by using too small supply voltage

wires) will cause the operator to malfunction. Batteries should be fully charged for proper operation, replace batteries every two

years on average.

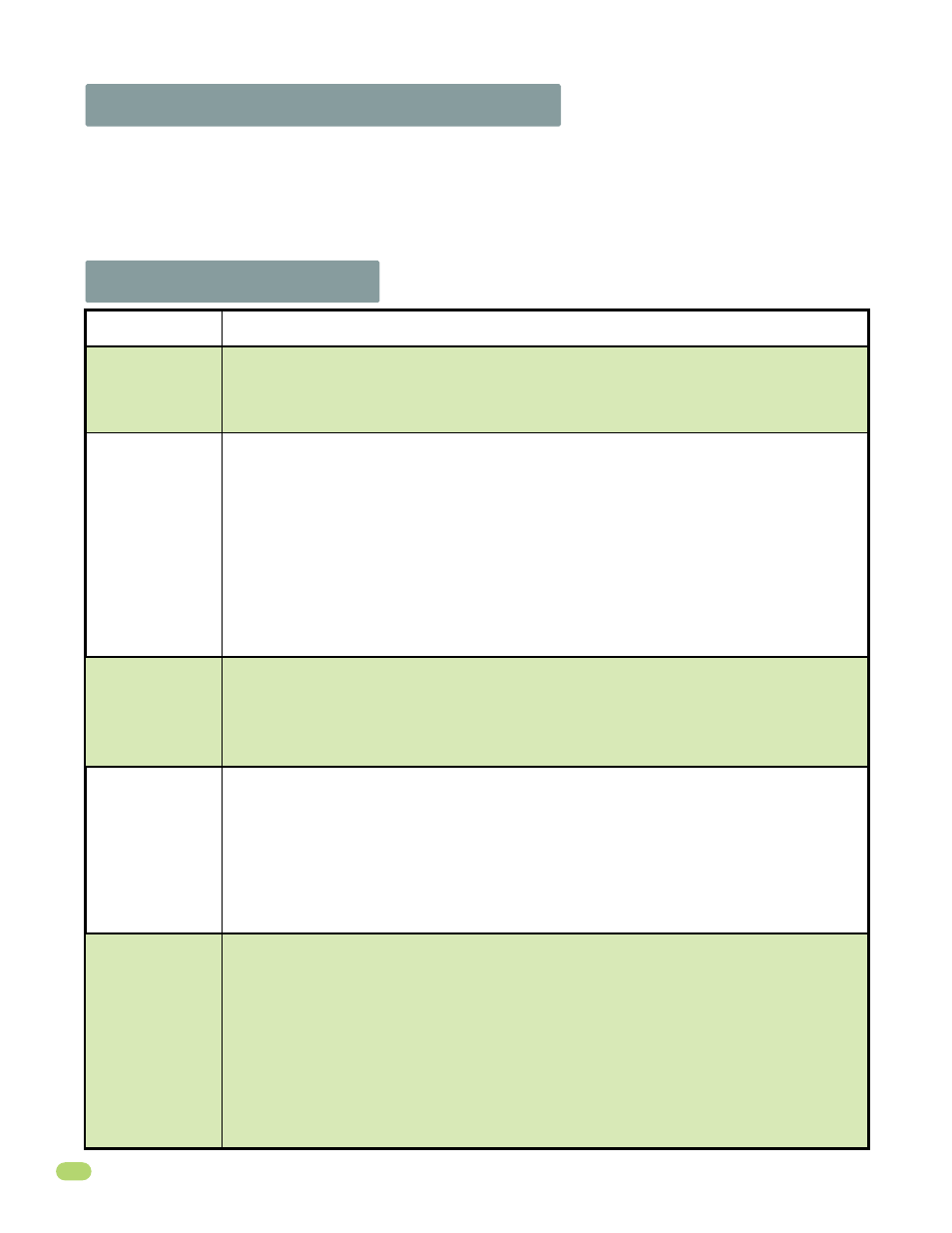

3.3 Troubleshooting

Symptom

Possible Solution

(

s

)

•

Check that AC power to the operator is turned ON.

•

Check battery power.

•

Check for 24 VAC at terminals 19 and 20. If voltage measures OK, check the terminal strip or

replace the circuit board.

Operator(s) will not

run. Power LED is

OFF.

•

Momentarily jumper terminal 1 to terminal 2. If the input LED does not come ON, check the terminal

strip or replace the circuit board. If LED does come ON, proceed to next steps.

•

Check the fuses.

•

Check Motor(s):

Remove the circuit board. With two 14 AWG insulated jumper wires, momentarily jumper the battery

terminals to the motor terminals (1, 2) of the Primary operator connector. The operator should run.

Swap the two wires at the terminal strip. The operator should run in the opposite direction. Repeat

these steps using the Secondary operator connector.

•

If the operator(s) run in both directions in the step above, replace the control board. If the

operator(s) do not run, or run in only one direction, problem can be a bad operator, wire

connections from the control board to the operator(s) or a bad control board.

•

Check the reversing sensitivity.

•

Check the secondary safety devices.

•

Disconnect the gate from the gate operator and check that the gate swings freely without any

binding.

•

Continue troubleshooting or replace the circuit board.

Operator(s) will not

run. Power LED is

ON.

•

Check the input LEDs. Any ON will hold the gate open and indicates a problem with a keying device.

•

Check the secondary safety devices. Any activated will hold the gate open and indicates a problem

with the safety device.

•

Check the loop detectors. Any activated can hold the gate open and indicates a problem with the

loop detector or ground loop.

•

Operator may be in a “soft shutdown.” Activate any keying device to determine if operator returns

to normal operation.

•

If automatic close is desired, be sure SW 1, switch 4 is ON.

Gate opens a short

distance, then stops

and reverses.

Gate opens but

will not close.

Gate closes but

will not open.

•

Operator may be in a “soft shutdown.” Check input LEDs. If any are ON, momentarily disconnect,

then re-connect the wire going to the respective terminal. Operator should open.

•

Check to be sure that the operator is running in the proper direction. Turn power OFF, and then back

ON. Activate a keying device. Operator should run in the open direction. If operator runs in the

close direction, turn power OFF and change direction switch SW 1, switches 1 and/or 2. Go to

above section if operator now opens but will not close.

•

Be sure that the respective LED on the control board lights when the keying device connected to the

respective terminal is activated. If LED does not light, momentarily place a jumper wire from

terminal 1 to the input terminal being checked. If LED lights and gate opens, problem is with the

keying device. If LED does not light, replace control board.

•

Check motor as described above “Operator(s) will not run. Power LED is ON”.