2 routine maintenance schedule, 3 validation (analytical quality assurance), Maintenance – Hach-Lange PHOSPHAX indoor sc User Manual

Page 43

43

Maintenance

6.2 Routine maintenance schedule

The maintenance schedule is given for standard applications.

Deviant applications may cause different maintenance intervals.

6.3 Validation (Analytical quality assurance)

Regular validation checks of the complete instrument must be

completed to make sure the analysis results are reliable.

Required parts:

•

Blind plug LZY193 (Plugging set LZY007)

•

Beaker (for example 150 mL)

•

Standard solution for validation

Follow the internal menu steps for the validation.

1. From the MENU select SENSOR SETUP>PHOSPHAX SC and

press ENTER.

2. Select MAINTENANCE>TEST/MAINT>VALIDATION>

DISCHARGE.

3. Enter the number of measurements which should be

discharged before starting the measurements of the validation.

(Default value: 2; value range: 1 to 5)

4. Select NUMBER OF MEAS..

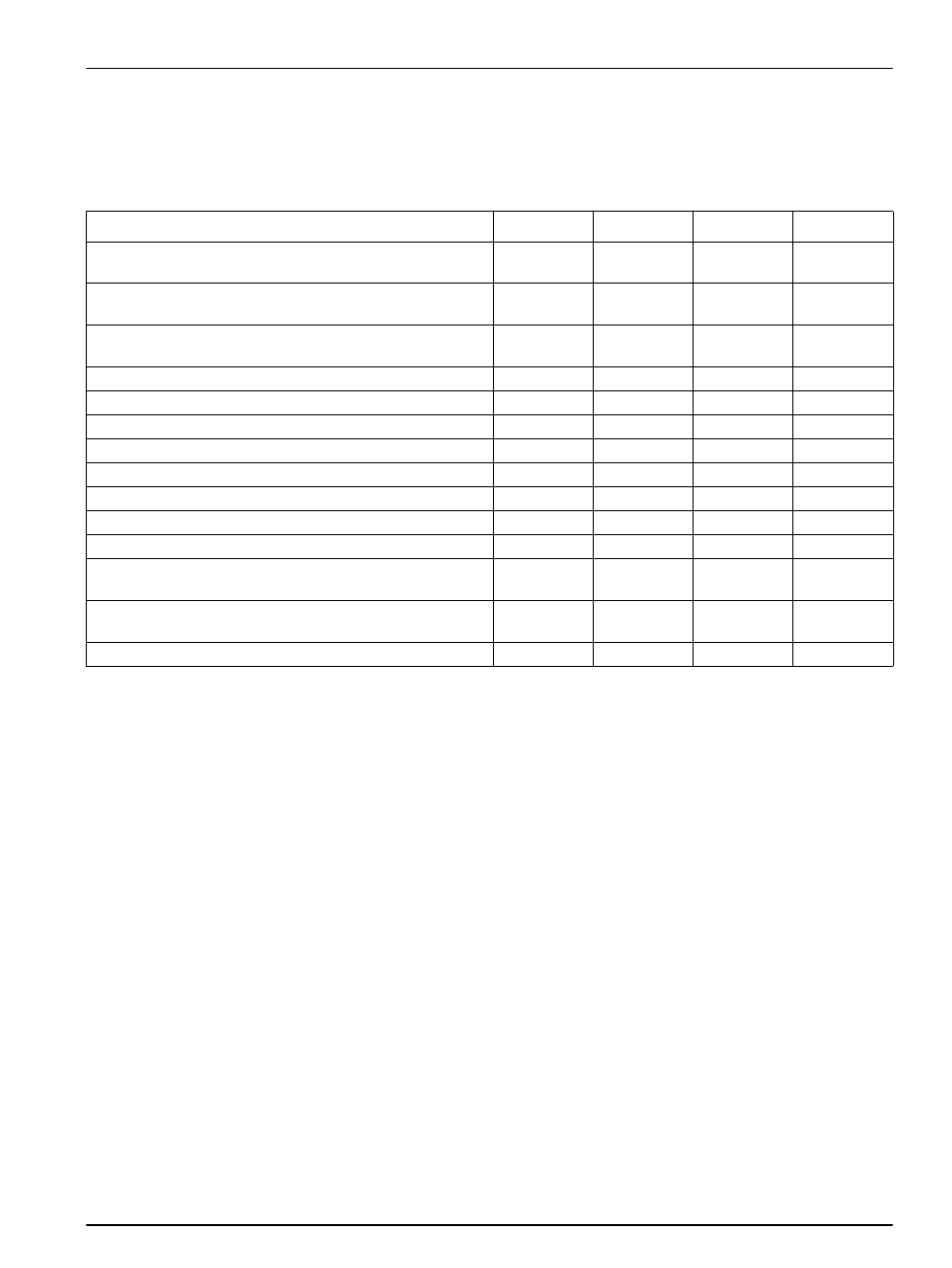

Table 4 Routine maintenance schedule

Description

3 months

6 months

12 months

24 months

Check measurement chamber and history of amplification

(event log).

X

1

Visual check analytical compartment, manual cleaning if

necessary.

X

1

X

Check filter pads, clean/ replace if necessary, particularly on

fan side.

X

1

X

Check reagents, replace if necessary.

X

1

X

Check cleaning solution, replace if necessary.

X

1

X

Check maintenance counters.

X

1

X

Function check of both fans.

X

Function check heating for analyser enclosure.

X

General function check.

X

Check system for air impermeability.

X

Clean manually and adjust cleaning interval if applicable.

X

Read out and analyse event log. Read out and check data log

if necessary.

X

Check reagent pump and replace if necessary (check every

6 months after 12 months of use).

(X)

2

X

Replace pump head for air pump.

X

1

Recommended, typical maintenance interval, especially for reagents. The actual reagent exchange intervals are depending on

configuration.

2

Maintenance cycles are given for standard applications. Deviant applications may cause different maintenance intervals.