Burkert Type 8750 User Manual

Page 19

19

Assembly

Typ 8750

Warning!

risk of injury from unsuitable connection hoses.

Hoses which cannot withstand the pressure and temperature

range may result in hazardous situations.

▶ Use only hoses which are authorized for the indicated pressure

and temperature range.

▶ Observe the data sheet specifications from the hose manufacturers.

procedure:

→

Connect the control medium to the pilot air port (1)

(3 – 7 bar; instrument air, free of oil, water and dust).

→

Fit the exhaust air line or a silencer to the exhaust air port (3).

Important information for the problem-free functioning of the

device:

• The installation must not cause back pressure to build up.

• To make the connection, select a hose with sufficient cross

section.

• The exhaust air line must be designed in such a way that

no water or other liquid can get into the device through the

exhaust air port (3).

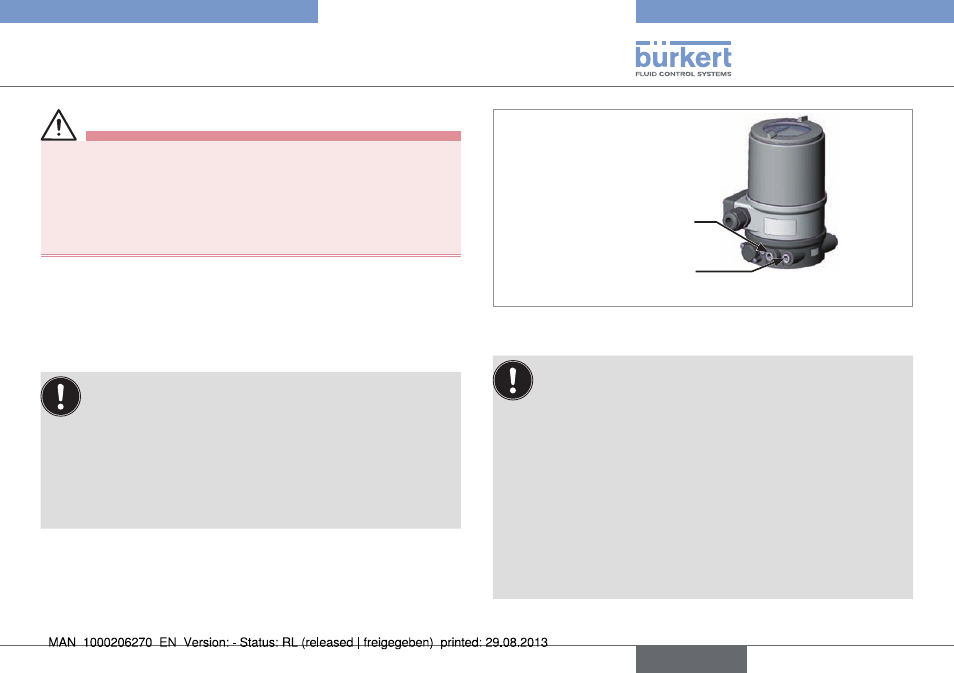

Pilot air port

label: 1

Exhaust air port

label: 3

Fig. 11: Pneumatic connection

Caution

(exhaust air concept):

In compliance with protection class IP67, an exhaust air line

must be installed in the dry area.

The applied pilot pressure must always be maintained at

least 0.5 – 1 bar above the pressure which is required

to move the pneumatic actuator to its end position. This

ensures that the control behavior is not extremely negatively

affected in the upper stroke range on account of too little

pressure difference.

During operation, keep the fluctuations of the pilot pressure

as low as possible (max. ±10 %). If fluctuations are greater,

the control parameters measured with the

X.TUNE function

are not optimum.

english