Profibus user manual – BEI Sensors PHU9 Absolute Hollow Shaft Encoder User Manual

Page 24

PROFIBUS USER MANUAL

24

Preliminary

BEI IDEACOD SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél

: +33 (0)3 88 20 80 80

Fax : +33 (0)3 88 20 87 87

Mail :

Web : www.bei-ideacod.com

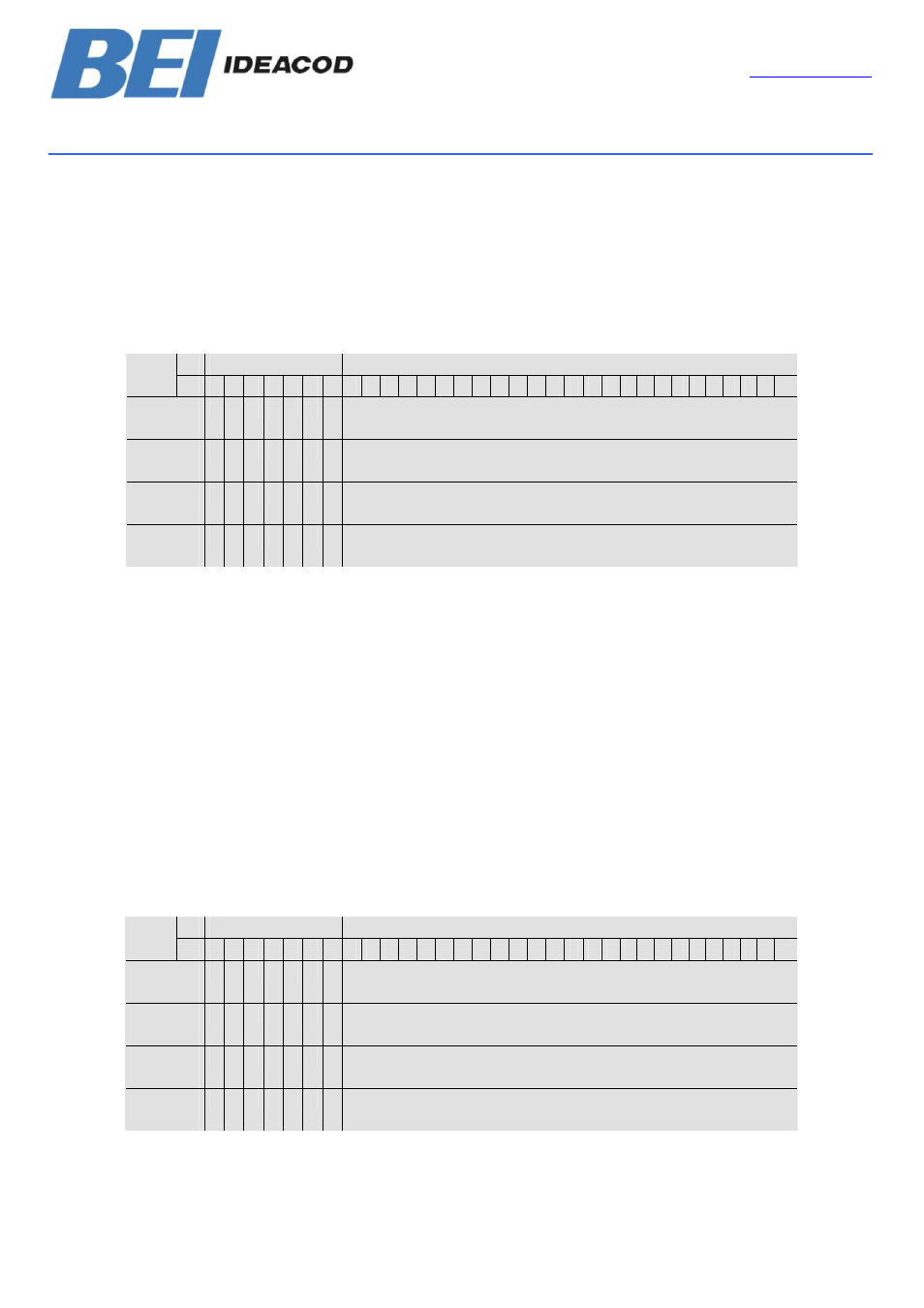

5.3.2 Teach-In Start

After the machine / system has been moved

to the start-position the Teach-In-Start

command is transmitted to the encoder. The

device now starts the internal calculation of a

new scaling factor.

Status bits

Data bits

Bit

31 30 29

28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Master

slave

0

1 0 0 0 0 0 Start the Teach-In by setting bit 30 to 1

Slave

Master

0

1 0 X X 0 1 Acknowledgement of the encoder by setting bit 30 to 1

Master

slave

0

0 0 0 0 0 0 Reset bit 30

Slave

Master

0

1 0 X X 0 1 Non-calculated position value is transmitted (gearing factor = 1, no offset)

Note: The scaling factor is set to 1; the zero

point shift is set to zero.

5.3.3 Teach-In Stop

After moving the machine / system to the

stop-position the Teach-In-Stop command is

send. Together with this command the desired

number of steps over the moved measuring

range is transmitted. The user has to observe

that the physical resolution is not exceeded

(e.g. 20000 steps on a quarter of a revolution).

Positive and negative directions are taken into

account automatically, also the crossing of

the physical zero point. Note: The measuring

range must not exceed the half physical

measuring range of the encoder (i.e. a

maximum of 32767 revolutions for a multiturn

device with 65536 revolutions.

After receiving the Teach-In-Stop command

the encoder transmits the calculated total

resolution. This value should be noted and

later (when switching the device to normal

mode) entered into the parameter settings.

After this Teach-In procedure the encoder

operates with the new gearing factor (which is

stored non-volatile in the internal EEPROM).

Status bits

Data bits

Bit

31 30

29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Master

SLAVE

0 0

1 0 0 0 0 Number of desired measuring steps (on the traversed measuring range)

SLAVE

Master

0 1

1 X X 0 1 Transfer of the total resolution (should be noted)

Master

SLAVE

0 0

0 0 0 0 0 Reset bit 29

SLAVE

Master

0 0

0 X X 0 1 Output of the current position value, scaled with the new gearing factor