BEI Sensors H40 Incremental Shock-Proof Encoder User Manual

H40 shock proof ordering options, H40 shock proof optical encoder, Mechanical specifications

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726 | 7230 Hollister Ave., Goleta, CA 93117-2807 |

www.beisensors.com

Specification No. 02045-001 Rev.08-11

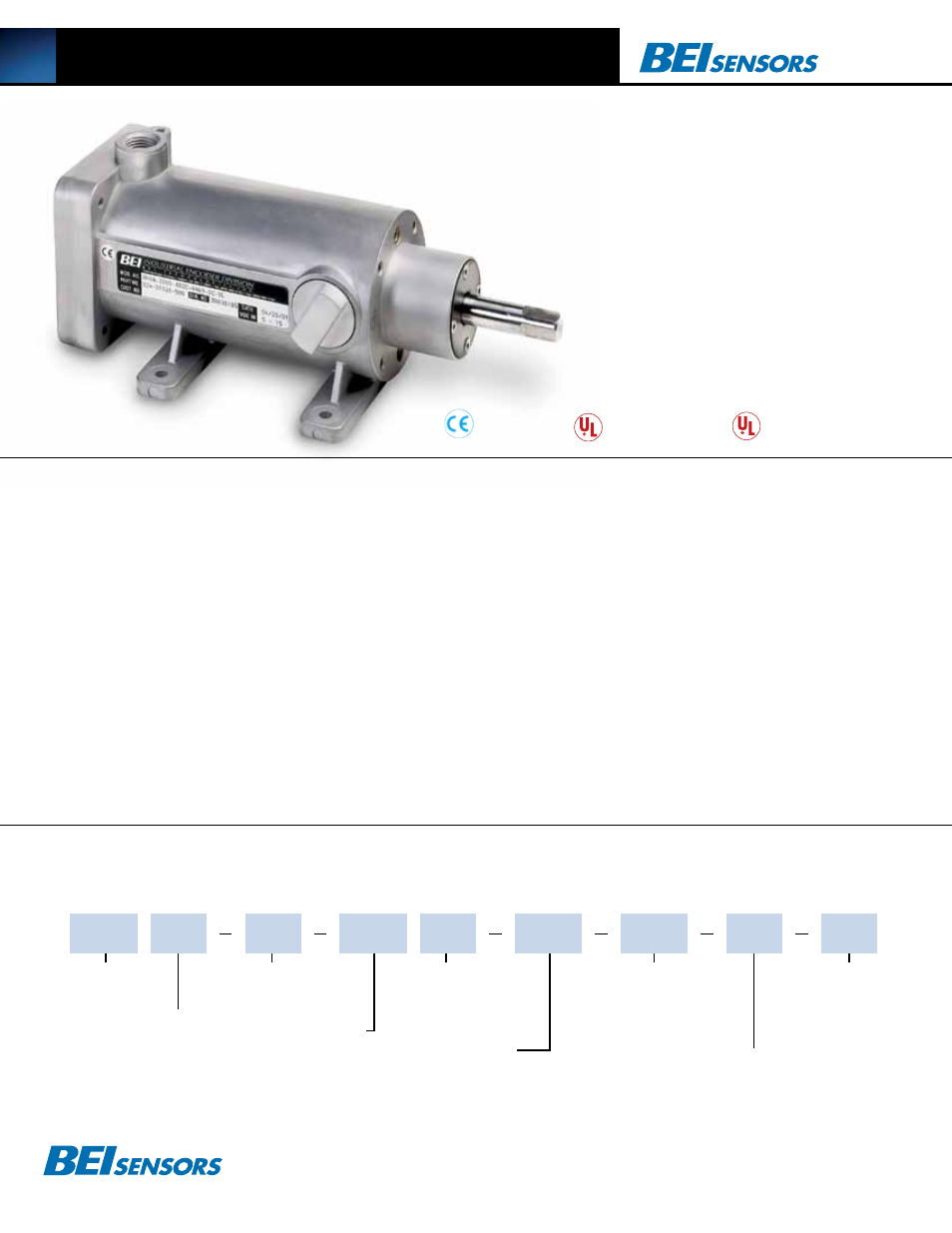

H40 Shock Proof Optical Encoder

The H40 is an ultra heavy duty encoder whose internal structure is totally

isolated from severe shock and shaft loading conditions. The optics and

electronics are supported in shock absorbing material within the heavy

cast outer housing. The encoder shaft is flexibly coupled to the high load

capacity bearings and shaft assembly, which is carried in the outer

housing. The entire bearing assembly is field-removable

to permit proper shaft support while pressing pul-

leys, gears, etc. onto the shaft. An Underwriters

Laboratories listed version of this model is available.

Mechanical Specifications

Shaft Diameter: 5/8” nominal

Flats On Shaft: Two flats, 0.75” long X 0.30” deep at 90º

Shaft Loading/Bearing Life: Refer to figure 1, back page

Shaft Runout: 0.001” T.I.R. at mid-point of shaft

Starting Torque at 25° C: 10.0 in-oz (max)

Bearings: Class 52100 SAE high carbon steel,

stainless steel option

Shaft Material: 1070 carbon steel, 303 and 316

stainless steel optional

Enclosure: Die cast aluminum, hard anodized with dichro-

mate sealed finish (optional). Shaft seals and sealed bearings

are standard to achieve environmental ratings.

Maximum RPM: 10,000 RPM (see frequency response, below)

Coupling Windup: The H40 uses an internal coupling.

Windup error (degrees) = a X 7.5 X 10

-4

rad/sec

2

where a = angular acceleration in rad/sec

2

Weight: Approx 9 lbs

Electrical Specifications

Output Format: 2 channels in quadrature, 1/2 cycle index

gated with negative B channel

Cycles per Shaft Turn: 1 to 72,000 (see Table 3).

For resolutions above 3,600 see interpolation options in the

BEI 2008 Spec Guide on pages 36 and 37.

Supply Voltage: 5 to 28 VDC available

Current Requirements: 100 mA typical + output load,

250 mA (max)

Voltage/Output: (see note 5)

15V/V: Line Driver, 5–15 VDC in, Vout = Vin

28V/V: Line Driver, 5–28 VDC in, Vout = Vin

28V/5: Line Driver, 5–28 VDC in, Vout = 5 VDC

28V/OC: Open Collector, 5 – 28 VDC in, OCout

Protection Level: Reverse, overvoltage and output

short circuit (see note 5)

Frequency Response: 100 KHz, up to 1 MHz with

interpolation option (see note 5)

Output Terminations: see Table 2, back page

Termination Type: Compression type, UL recognized.

Accepts AWG 14 to 22, stranded wire, strip 1/4”

Note: Consult factory for other electrical options

Environmental Specifications

Enclosure Rating: NEMA 4 X & 6 (IP66), outdoor

Non-Hazardous locations, NEMA 4 X & 13 (IP66),

indoor Non-Hazardous locations

Hazardous Area Rating: The optional Underwriters

Laboratories listed version is for use in hazardous locations;

NEMA Enclosure 7. Class 1, Group D, Division 1,

NEC Class 2 circuits only

Temperature: Operating, 0º to 70º C; extended temperature

testing available (see note 6); 80º C max for UL and CEN

approved units; storage; -25º to 90º C

Shock: 200 g’s at 11msec

Vibration: 5 to 2000 Hz @ 20 g’s

Humidity: 100% RH

H40 Shock Proof Ordering Options

for assistance call 800-350-2727

Use this diagram, working from left to right to construct your model number (example:

H40A-2000-ABZC-28V/V-SC-UL).

All notes and tables referred to can be found on the back of this page.

NOTES & TABLES:

All notes and tables referred to in the text can be found on

the back page.

The H40 Shock Proof Encoder is avail able with the following certifications:

C

Canadian Standards Class I,

Group D, Division 1

U.S. Standards Class I,

Group D, Division 1

EN 55011 and

EN 61000-6-2

TYPE:

H = Heavy Duty;

40 = 4.00” Square

NO. OF CHANNELS:

A = Single Channel

AB = Dual Quad. Ch.

ABZ = Dual with Index

AZ = Single with Index

See note 1

VOLTAgE/OuTPuT:

15V/V = 5–15 Vin/out

28V/V = 5–28Vin/out

28V/5 = 5–28Vin/5Vout

28V/OC = 5–28Vin/

OCout

See note 3

HOuSINg

CONFIguRATION:

A = Base Mounted Feet

B = No Mounting Feet

COMPLEMENTS:

C = Complementary

Outputs,

Blank = None

See note 2

OuTPuT TERMINATION:

SC = Side Conduit

EC = End Conduit; Conduit uses 1/2–14

NPSF (dryseal) straight pipe threads;

EM16 = MS3102R16S-1P

EM18 = MS3102R18-1P,

See Table 1, back page

CERTIFICATION:

UL = UL Explosion

Proof rating, only

available with SC

termination

SPECIAL

FEATuRES:

S= Special

features specified

on purchase order

(consult factory)

See note 4

CYCLES PER TuRN:

Enter Cycles

See Table 3

H40