BEI Sensors IBK5 Incremental Hollow Shaft Encoder User Manual

Ihk5, Atex incremental encoders, ihk5 range

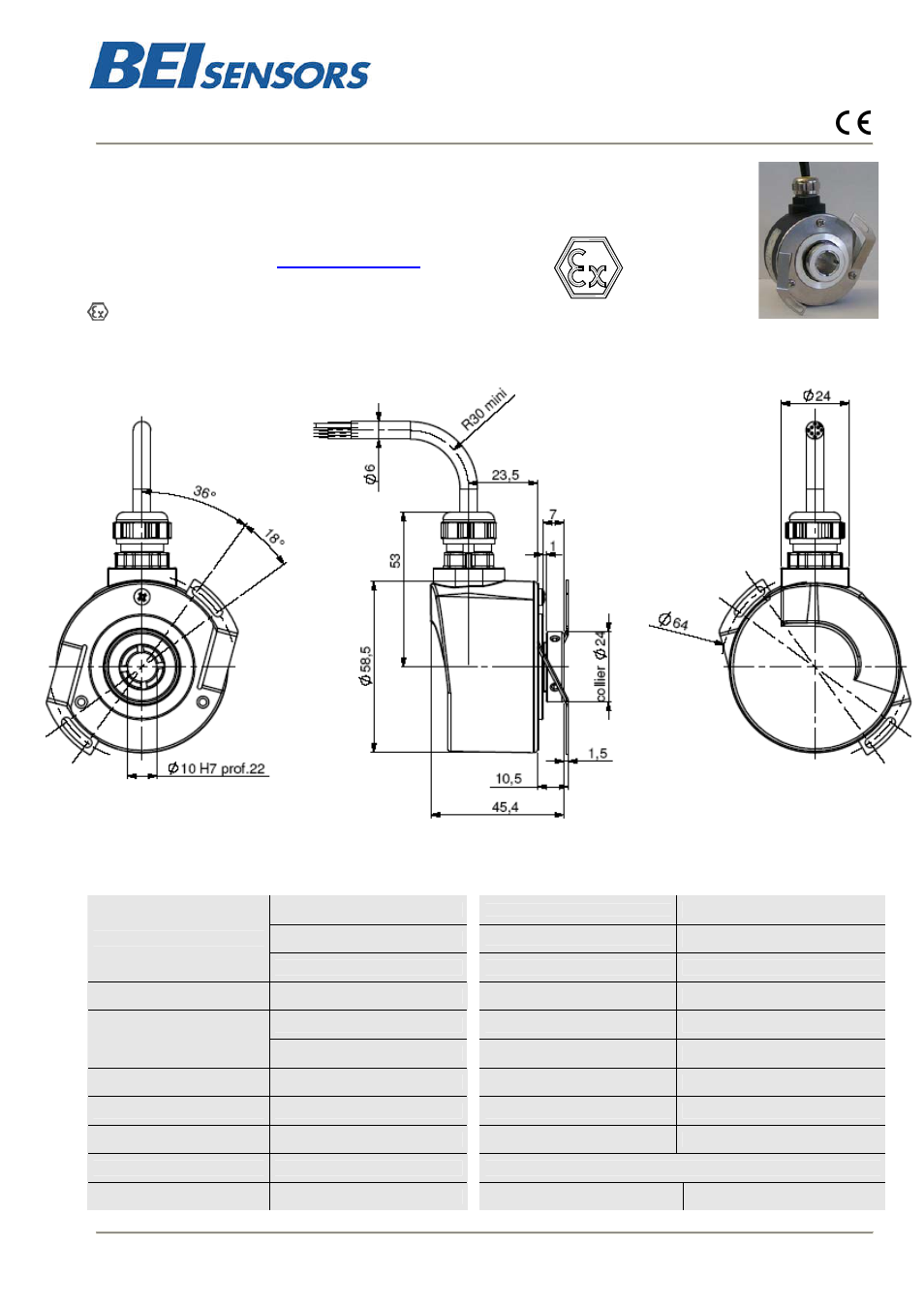

IHK5

BEI Sensors SAS

Espace Européen de l’Entreprise

9, rue de Copenhague

B.P. 70044 Schiltigheim

F 67013 Strasbourg Cedex

Tél

: +33 (0)3 88 20 80 80

Fax

: +33 (0)3 88 20 87 87

Web :

www.beisensors.com

ATEX INCREMENTAL ENCODERS, IHK5 RANGE

Intrinsically safe encoders, specially designed for explosive GAZ or DUST atmospheres

For chemical applications (painting, solvent, fragrances, rubber), textile, food processing,

wood, petrochemistry…

EC type examination certificate

Download from our website

www.beisensors.com

LCIE 04 ATEX 6109 X

CE 0081

II 1 G/D EEx ia IIC/B T4 Ex iaD 20 T135°C

IHK5_10 connection G3R (radial cable), DAC 9445/016 mounted onto the body

Minimal Depth for an optimal centring: 12mm

CHARACTERISTICS

Cover : zinc alloy

Shock (EN60068-2-27)

500 m.s

-2

(during 6 ms)

Body : aluminium

Vibration (EN60068-2-6)

100 m.s

-2

(55 … 2 000 Hz)

Material

Shaft : stainless steel

CEM

EN 50081-1, EN 61000-6-2

Bearings

6 803 serie

Isolation

1 000 V

Axial : 20 N

Weight (connector)

0,3 kg

Maximal load

Radial : 50 N

Operating temperature

- 30 ... + 70°C (encoder T°)

Shaft inertia

2,2.10

-6

kg.m

2

Storage temperature

- 30 ... + 100°C

Torque

6.10

-3

N.m

Protection(EN 60529)

IP 65

Permissible max.speed

6 000 min

-1

Torque (ring pressure screw)

nominal: 1.5 N.m, break: 2.0 N.m

Continuous max. speed

6 000 min

-1

Theoretical mechanical lifetime 10

9

turns (F

axial

/ F

radial

)

Shaft seal

Viton

10N / 25N : 230

20N / 50N : 29

Changes possible without further notice - Version 080919