BEI Sensors HS35 Express Encoder User Manual

Hs35 incremental ordering options, Hs35 incremental optical encoder, Mechanical specifications

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807 |

www.beisensors.com

Specification No.

924-02063-001 Rev.08-13

These commodities, technology or software if exported from the United States must be in accordance with the Bureau of Industry, and Security, Export Administration regulations. Diversion contrary to U.S law is prohibited.

Mechanical Specifications

Shaft Bore:

1.00”, 0.875”, 0.750”, 0.625”, 0.500”.

All are supplied with insulating sleeves.

Allowable Misalignment:

0.005” T.I.R. on mating shaft 0.75” from shaft end

Bore Runout:

0.001” T.I.R maximum

Starting Torque at 25°C:

Through shaft version (SS) = 7 in-oz (max);

Blind shaft version (BS) = 4 in-oz (max)

Bearings:

52100 SAE High carbon steel

Shaft Material:

416 stainless steel

Bearing Housing:

Die cast aluminum with protective finish

Cover:

Die cast aluminum with protective finish

Bearing Life:

7.5 X 10

9

revs (50,000 hrs at 2500 RPM)

Maximum RPM:

6,000 RPM (see Frequency Response below)

Moment of Inertia:

0.019 oz-in-sec

2

Weight:

18 oz typical

Electrical Specifications

Code:

Incremental

Output Format:

2 channels in quadrature, 1/2 cycle index gated with negative B channel

Cycles Per Shaft Turn:

1 to 80,000 (see table A, page 25).

For resolutions above 5000 see interpolation options on pages 36 and 37

Supply Voltage:

5 to 28 VDC available (see note 5)

Current Requirements:

100 mA typical + output load, 250 mA (max)

Voltage/Output:

(see note 5)

28V/V: Line Driver, 5–28 VDC in, Vout = Vin

28V/5: Line Driver, 5–28 VDC in, Vout = 5 VDC

28V/OC: Open Collector, 5–28 VDC in, OCout

Protection Level:

Reverse, overvoltage and output short circuit (See note 5)

Frequency Response:

150 kHz (up to 5000 cpt resolution; 300 KHz above 5000

cpt, also see note 7)

Output Terminations:

See table 1 page 65

Note:

Consult factory for other electrical options

Environmental Specifications

Enclosure Rating:

NEMA 4 & 13 (IP65) when ordered with shaft seal (on units

with an MS connector) or a cable gland

(on units with cable termination)

Temperature:

Operating, 0º to 70º C; extended temperature testing up to 105º C

available (see note 8); Storage, -25º to

90º C unless extended temperature option called out

Shock:

50 g’s for 11 msec duration

Vibration:

5 to 2000 Hz @ 20 g’s

Humidity:

98% RH without condensation

NOTES & TABLES: All notes and tables referred to in the text can be found on the

back of this page.

Special Models of the HS35 Incremental Encoder are available with one or more of the

following certifications. Consult factory for details.

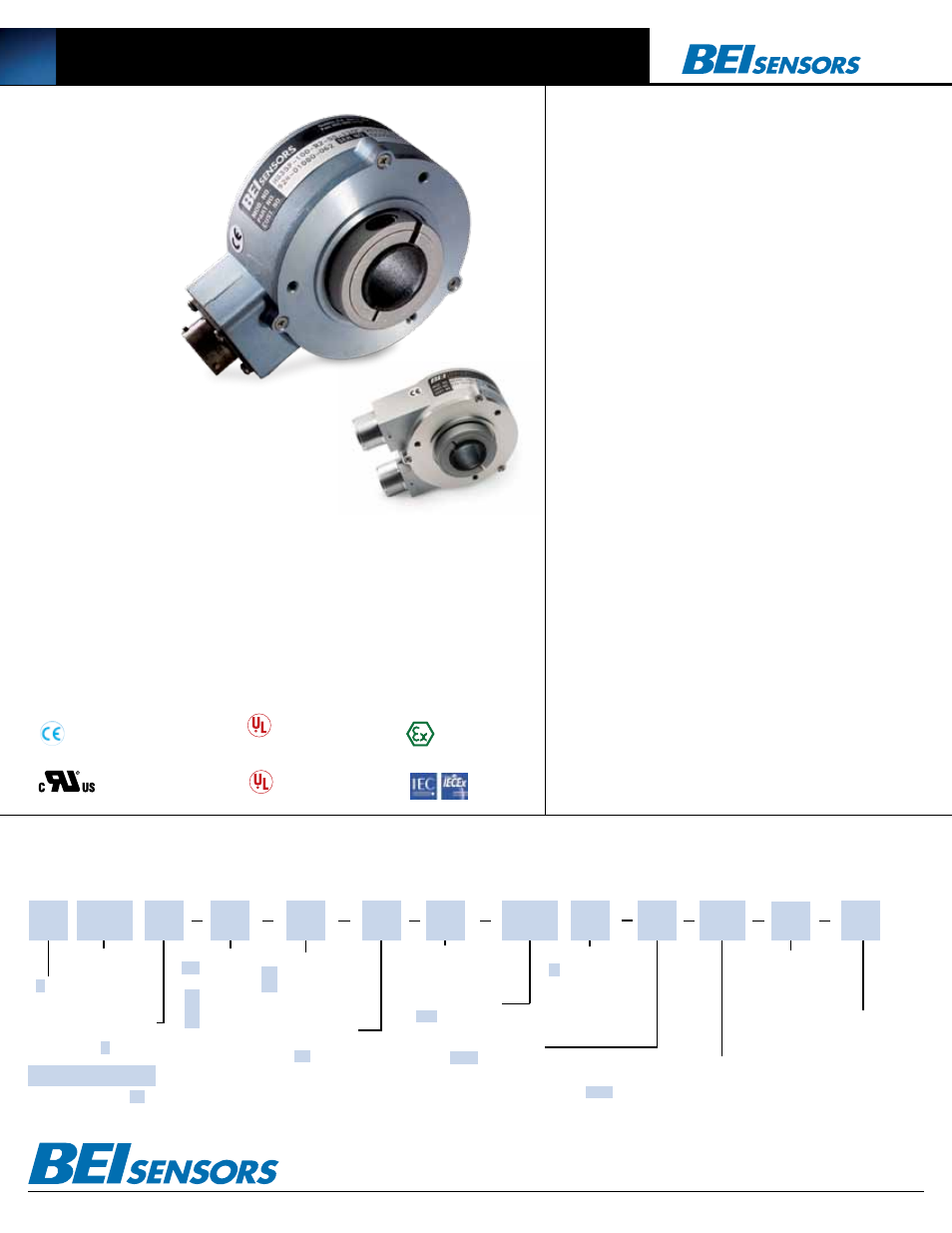

The HS35 com-

bines the rug-

ged, heavy-duty

features usually

associated with

shafted encod-

ers into a hollow

shaft style. Its

design includes

dual bearings

and shaft seals

for NEMA 4, 13 and

IP65 environmental

ratings, a rugged metal

housing, and a sealed connector or

cable gland. The HS35 accommodates

shafts up to 1” in diameter. With optional

insulating inserts, it can be mounted

on smaller diameter shafts. It can be

mounted on a through shaft or a blind

shaft with a closed cover to maintain its environmental rating. The HS35 is also

available with a dual output option (inset) to provide redundant encoder signals,

dual resolutions, or to supply two separate controllers from a single encoder.

Applications include motor feedback and vector control, printing industries,

robotic control, oil service industries, and web process control.

The HS35 Dual Output Encoder

NO. OF CHANNELS:

ABZ See note 3

COMPLEMENTS:

C = Complementary

Outputs

See note 4

TYPE:

HS = Hollow Shaft

35 = 3.5” Encoder

Diameter

CYCLES PER TuRN:

(Enter Cycles)

See table A on back page

SPECIAL FEATuRES:

S = Special

features specified

on purchase order

(consult factory)

See note 6

HAzARDOuS

AREA RATINgS:

Blank = None

EX = Intrinsically Safe

NI = Non-Incendive

Contact factory for

voltage options

OuTPuT TERMINATION:

SM12 = MS3112E12-10P, M16 = MS3102R16S-1P

SM18 = MS3102R18-1P

(Indicate “S” for single or “D” for Dual (i.e. DM18 = Dual)

SCS = Shielded, Jacketed Cable with cable gland seal and

cable length in inches. (i.e. SCS18 = 18 inches)

TB = Terminal Block (See table 1 & note 9)

HOuSINg

CONFIg:

F = Standard

X =

Express

Encoder

VOLTAgE/OuTPuT:

28V/V = 5–28Vin/out

28V/5 = 5–28Vin/5Vout

28V/OC = 5–28Vin/OCout

See note 5

SHAFT SEAL

CONFIguRATION:

SS =Through Shaft Rubber Seals

BS = Blind Shaft Rubber Seal

FS = Through Shaft Felt Seals

BFS = Blind Shaft Felt Seal

See Note 2

TETHER:

R1 = Tether Block and Pin

R2 = Tether Arm

Blank = None

SHAFT BORE:

100 = 1.00”

87 = 0.875”

75 = 0.75”

62 = 0.625”

50 = 0.50”etc.

Metric bores available

HS35 Incremental Ordering Options

FoR ASSiSTANCe CAll 800-350-2727

Use this diagram, working from left to right to construct your model number (example:

HS35F-100- R1-SS-2048-ABZC-28V/V-SM18).

All notes and tables referred to can be found on the back of this page.

HS35

EXPRESS ENCODERS

®

Items highlighted with are standard Express

Encoders and ship in one to three days.

T2 option is available as a standard HS35 Express Encoder.

HS35 Incremental Optical Encoder

C

Canadian Standards

Class I, Zone 0, Group IIC

U.S. Standards Class I,

Group A,B,C & D;

Class II Group E, F & G

CENELEC

II 1 G Ex ia IIB/IIC T4

II 3 G Ex nA IIB T4 Gc

Class I, Div 2, Group A,B,C & D;

Class II, Div 2, Group F & G

UL 12.0035X

UL 12.0082X

EN 55011 and EN 61000-6-2