BEI Sensors H38 Absolute Explosion Proof Encoder User Manual

H38 absolute encoder ordering options, H38 absolute explosion-proof encoder, Electrical specifications

Tel: 805-968-0782 /800-350-2727 | Fax: 805-968-3154 / 800-960-2726

7230 Hollister Ave., Goleta, CA 93117-2807 |

www.beisensors.com

Specification No. 02051-002 Rev.08-11

These commodities, technology or software if exported from the United States must be in accordance with the Bureau of Industry, and Security, Export Administration regulations. Diversion contrary to U.S law is prohibited.

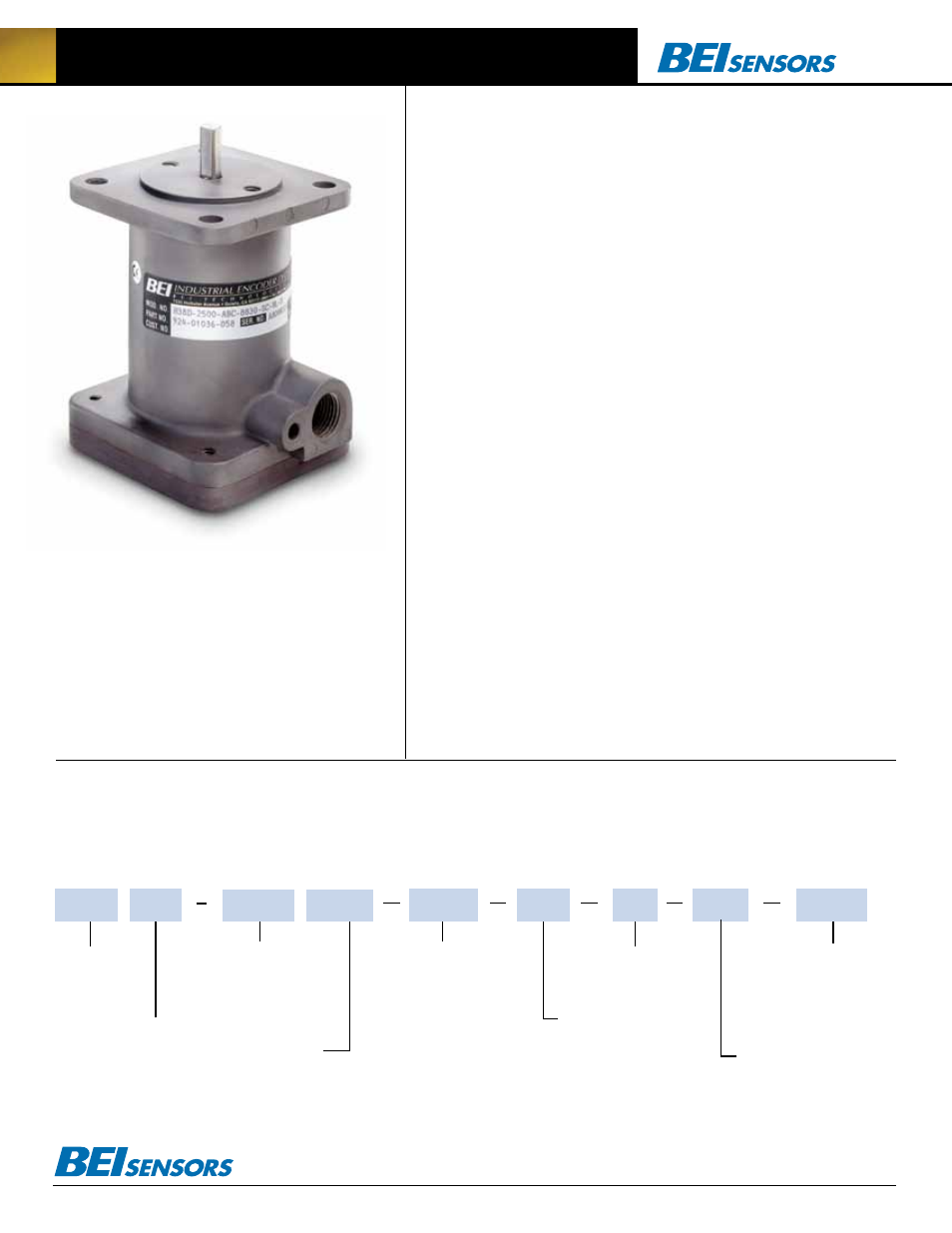

H38 Absolute Explosion-Proof Encoder

This is the same Explosion Proof rated encoder as the

H38 Incremental, in an absolute encoder version with

output up to 13 bits of resolution. When your application

needs the ability to recover position information quickly

after a power loss and you are operating in a hazardous

area—the H38 may be the answer to your needs.

Electrical

Specifications

Code: 12 or 13 bits NB or GC; excess gray

and BCD available

Counts Per Shaft Turn: 4096 or 8192

Count Transition Accuracy:

± 1/2 bit maximum

Supply Voltage: 5–28 VDC

Current Requirements: 120 mA typical

Output Formats: Parallel: Gray Code,

Natural Binary and Binary Coded Decimal;

Serial: Serial Synchronous Interface (SSI);

Analog: 4–20 mA, 0–10V

Voltage/Output: (see note 5)

28V/V: Line Driver, 5–28 VDC in, Vout = Vin

28V/5: Line Driver, 5–28 VDC in, Vout = 5 VDC

28V/OC: Open Collector, 5–28 VDC in OCout

SSI: 5–28 VDC in/5Vout

Protection Level: Reverse, overvoltage and

output short circuit protection

Frequency Response: 100kHz (1200 RPM for

12-bits, 600 RPM for 13-bits)

Output Termination Pinouts:

See table 3, back page

Mechanical

Specifications

Shaft Diameter: 3/8” nominal

Flats On Shaft: Two flats, 0.80” long X 0.30”

deep at 90º

Shaft Loading: Up to 40 pounds axial and 20

pounds radial applied 1/4” from housing

Shaft Runout: 0.0005 T.I.R.

Starting Torque at 25° C: 4.0 in-oz (max)

Bearings: Class ABEC 7 standard

Shaft Material: 303 stainless steel

Enclosure: Die cast aluminum, hard anodized

with dichromate sealed finish. Shaft seals

and sealed bearings are standard to achieve

environmental ratings.

Bearing Life: 2 X 10

8

revs (1300 hrs at 2500

RPM) at rated load; 1 X 10

10

revs (67,000 hrs at

2500 RPM) at 10% of rated load

Maximum RPM: 10,000 RPM (see frequency

response, below)

Moment of Inertia: 4.1 X 10

–4

oz-in-sec

2

Weight: 64 oz typical (approx 4 lbs)

Environmental

Specifications

Enclosure Rating: NEMA 4 X & 6 (IP66), out-

door Non-Hazardous locations, NEMA 4 X & 13

(IP66), indoor Non-Hazardous locations

Temperature: Operating, 0º to 70º C;

extended temperature testing available (see

note 8, pg 64); 80º C max for UL and CEN

approved units; storage; -25º to 90º C.

Shock: 50 g’s at 11 msec

Vibration: 5 to 2000 Hz @ 20 g’s

Humidity: 100% RH

Hazardous Area Rating: Underwriters

Laboratories listed for use in hazardous

locations; NEMA Enclosure 7. Class 1,

Group C & D, Division 1, NEC Class 2

circuits only, or Class 2, Groups E, F,

and G (see Table 1)

NOTES & TABLES: All notes and tables

referred to in the text can be found on the

back of this page.

CODE TYPE:

GC = Gray Code

NB = Natural Binary

BCD = Binary Coded Decimal

X = Excess gray code

HOUSING

CONFIGURATION:

D = Standard

H38 Absolute Encoder Ordering Options

FoR ASSiSTANCe CAll

800-350-2727

Use this diagram, working from left to right to construct your model number (example:

H38D-12GC-28V/V-CW-SC-UL).

All notes and tables referred to can be found onthe back of this page.

TYPE:

H = Heavy Duty;

38 = 3.75”

Square

NUMBER OF BITS:

12 = 12-Bits, 4096 counts per turn

13 = 13 Bits, 8192 counts per turn

14, 15, bits and HMT—Consult factory

(Excess gray codes and BCD

available–consult factory)

CERTIFICATION:

UL = Class I Group D Environments

CEN = UL Class I & II, Cenelec IIB Environments

VOLTAGE/OUTPUT:

28V/V = 5-28Vin/out

28V/5 = 5-28Vin/5Vout

28V/OC = 5-28Vin/OCout

A1 =4-20mA

A2 =0-10V

S1 = RS422 Asynchronous

Serial Interface

S3 =Serial Synchronous

Interface

(See note 5 and page 46 of the

2008 BEI Specifying Guide for SSI)

OUTPUT TERMINATION:

SC = Side Conduit, 1/2–14 NPSF

(dryseal) straight pipe threads

DIRECTION

OF COUNT:

CW = Clockwise

increasing count

CCW = Counter

clockwise increasing

count

SPECIAL FEATURES:

S = Special features specified

on purchase order

(consult factory)

See note 6

H38