Climax BB6100 LINE BORING MACHINE User Manual

Bb6100 boring machine

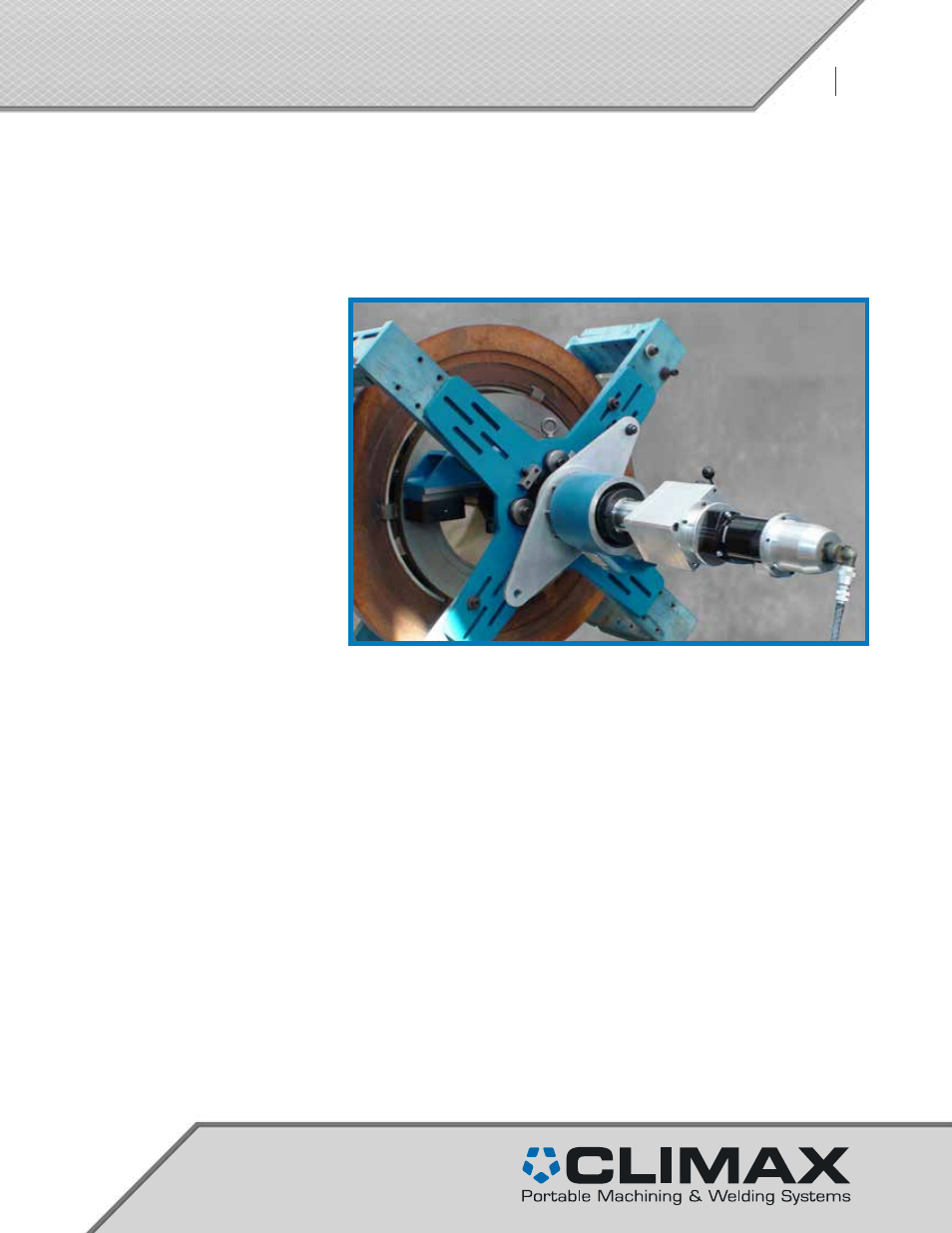

BB6100 Boring Machine

Packing big boring capability into a compact, modular

machine, maximizing efficiency and minimizing downtime.

Powerful Yet Compact

• Take the power of a stationary machine to the

job site to solve tough machining challenges in

record time.

• Using the 11.3 in

3

(185.3 cm

3

) Hydraulic

motor, it produces 1435 ft•lb (1945.6 N•m) of

torque at the bar, at 33 rpm.

• Compact, modular components allow fast,

easy setup, maximizing efficiencies, and

minimizing downtime.

Versatile and Flexible

• Huge machining range bores from 8.8 - 38.0

inches (223.5 - 965.2 mm) in diameter, and

faces from 7.5 - 42.1 inches (190.5 - 1069.3

mm) with various facing attachments.

• ID and End Mount Bearings feature spherical

taper-lock roller bearings for easy setup and

removal of the bar, and allow for up to 1.5

degrees of misalignment when setting up

bearings.

• End mount bearings can be fine adjusted by

+/- 0.625 inches (15.9 mm) to center the bar.

• Optional dual action boring/facing arms

increase facing range, and allow for both

boring and facing without switching equipment.

Full-length square ways on boring/facing arms

allow for quick positioning anywhere along

the arm. Attaches to the net fit tool carrier by

compression-clamping, to provide maximum

tool stability.

• Net fit tool carrier can be clamped to bar for

facing operations. For boring operations,

carrier can be adjusted to remove clearance

between carrier and the bar. This flexibility

also ensures maximum rigidity for either

operation.

• For even greater facing range and longer

continuous stroke, the new boring/facing arms

are available. Setup is quick & easy for both

boring and facing operations.

• Net fit tool carrier is designed with a split frame

to simplify installation on the boring bar. It can

be configured to use either the boring head

set for boring, the mechanical facing head for

facing, or the new boring/facing arm assembly

for both boring and facing operations.

• With leading & trailing boring head

configuration, 2 boring heads can be used

simultaneously.

• Highly versatile tool holder block accepts

industry standard tooling with a nominal ¾

inch (19.1 mm) square shank.

• Tool post on the boring/facing arm can be

rotated to provide maximum flexibility in

machining setup (including some cantilevered

configurations).

High Quality Design

• Features a uniquely-designed modular tool

carrier which provides a new level of strength

and rigidity by channeling machining forces

directly to the boring bar through strategically-

located adjustable guide shoes.

• Durable chromed bars, straight to within 0.001

inch per foot (0.0254 per 304.8 mm) ensure

accurate machining.

• Adjustable, removable half nut increases net

fit tool carrier flexibility. Easy removal of tool

carrier allows for machining of multiple bores.

• Backlash adjustment nut allows in-the-field

adjustment to eliminate backlash in the tool

carrier, and extend the life of the machine.

2013

BB61

1