Climax VM8000 GLOBE/CONTROL VALVE REPAIR User Manual

Page 5

For help contact: Climax Portable Machine Tools, P.O. Box 1210, Newberg, OR 97132 USA Website: www.cpmt.com

Worldwide Phone: 503.538.2185

USA/Canada Toll-Free: 800.333.8311

Fax: 503.538.7600

Email: [email protected]

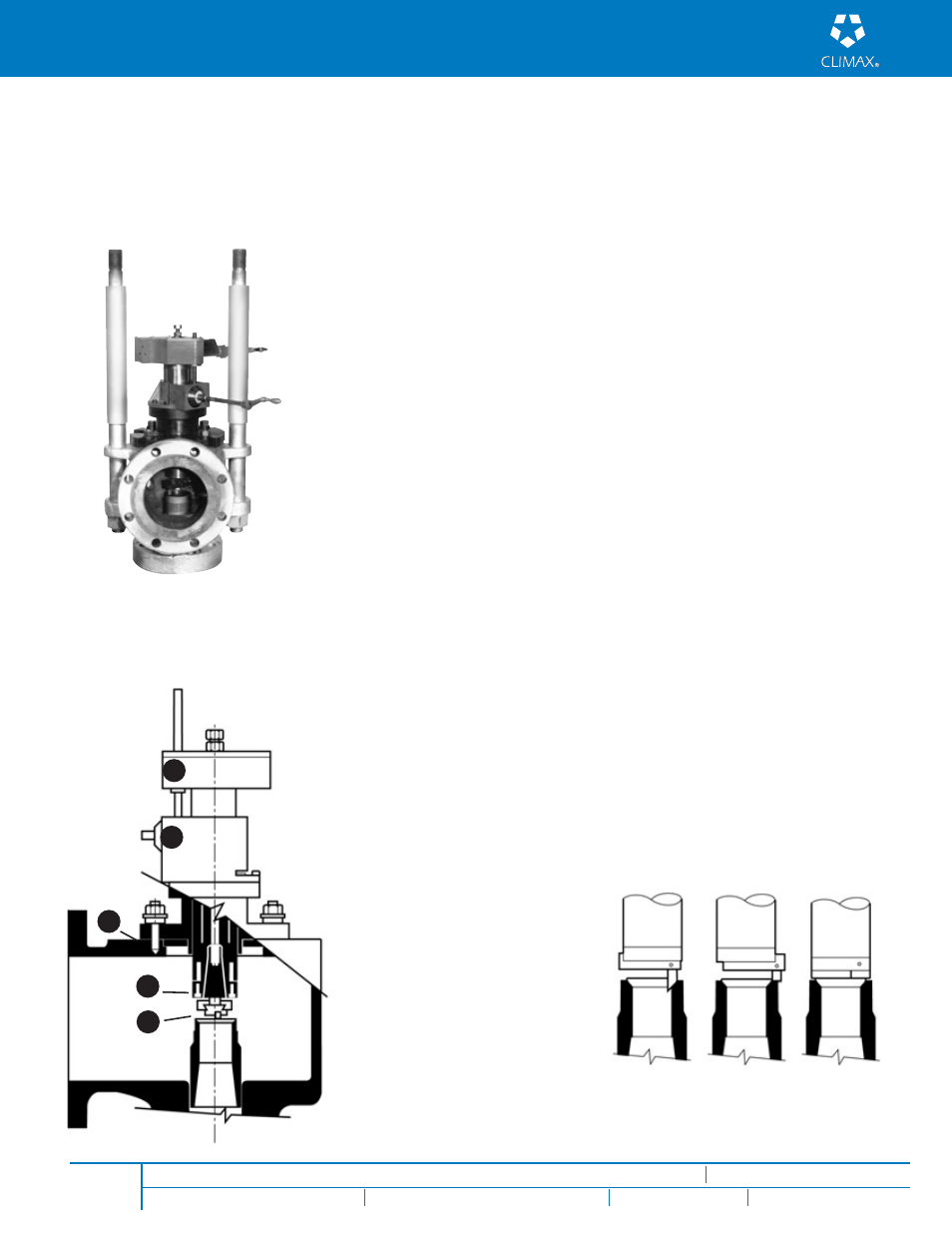

V M 7 0 0 0 V a l v e R e p a i r M a c h i n e

page 5

If the valve was welded in-line, eliminate

rewelding and recertification by

remachining in place. By eliminating

downtime and spare valve inventory

costs, you can probably pay for the

Model VM7000 by repairing just a few

valves in-line.

Capabilities

The Model VM7000 is designed to

mount directly on safety valves and

rework nozzles up to 4 inches (101.6

mm) in diameter. The VM7000 will

mount on Dresser Consolidated

Maxi-Flow valves, orifice sizes 1 through

6, and on many Crosby Safety Valves.

Any safety valve with a similar

configuration can be repaired with the

VM7000 (optional modified mounting

fixtures may be needed). Combine the

various tool bits and tool holders to

remachine valve bushing seats to the

manufacturer's original specifications.

Machine outside diameter, inside

diameter, and bushing seat faces to

close tolerances.

Features

The VM7000 consists of a compact

pneumatic power head and spindle, a

set of mounting fixtures, and tool heads

for a range of machining operations.

The power head features a 1.2 hp (0.90

kW) pneumatic motor that drives a

worm gear reduction, for plenty of

torque at the tool head. The spindle

turns in ball bearings to ensure smooth

operation.

The tooling assembly consists of the tool

head, the tool set fixture, the boring and

facing heads, and the tool bits. A draw

bolt holds the tool head to the spindle.

The tooling assembly does three basic

valve remachining operations: boring,

turning and facing.

The VM7000 mounts on the valve with

a fixturing assembly that consists of

mounting fixtures, adapter rings and

clamp bars. The adapter ring, machined

to fit standard valve bore sizes, centers

and aligns the machine in the valve

opening. The adapter ring raises the

machine slightly above the flange

surface to ensure alignment with the

valve axis, even if the valve face is

uneven due to corrosion. The valve

mounting fixture uses existing valve

flange studs.

Now you can repair a safety valve in about

the same time it would take to remove the

damaged valve.

1. Rotational drive box

2. Quill

3. Valve mounting fixture

4. Removable tool head

5. Axial feed control

1

5

3

2

4

Boring

Turning

Facing

Three tool configurations and

machining operations for the VM7000