Climax VM8000 GLOBE/CONTROL VALVE REPAIR User Manual

Page 2

For help contact: Climax Portable Machine Tools, P.O. Box 1210, Newberg, OR 97132 USA Website: www.cpmt.com

Worldwide Phone: 503.538.2185

USA/Canada Toll-Free: 800.333.8311

Fax: 503.538.7600

Email: [email protected]

V M 6 0 0 0 V a l v e R e p a i r M a c h i n e

page

2

Valves are often damaged in the throat

area by corrosion or steam cavitation.

Now you can eliminate remove/replace

downtime and expense by repairing the

worn valve while you leave it in-line.

The Model VM6000 Portable Valve

Repair Machine makes on-site repair of

a wide range of valves practical. With

the VM6000, you remove the valve

bonnet assembly to allow access to the

valve throat, machine a weld prep

groove, apply a weld build-up as

necessary in the eroded area. in the

eroded area, and bore out the valve

throat to original dimensions.

Capabilities

The Model VM6000 is a “generic” valve

repair machine that mounts on and bores

the throat area of any valve the mounting

fixtures can attach to. Using three mount-

ing ring sizes, the VM6000 mounts directly

on valves with outside flange diameters

from 3.5 - 17 inches (88.9 - 431.8 mm). It

machines inside diameters from 2.5 - 13

inches (63.5 - 330.2 mm). The VM6000 is

capable of boring inside diameters, turning

outside diameters, undercutting, and

cutting recesses and grooves.

Features

The VM6000’s power head long ago

proved its rugged dependability in our

Model FF12 portable flange facing

machine. The 1.2 hp (0.90 kW) pneumatic

motor and gear reduction provide

plenty of torque for remachining valves.

The mounting fixtures, which form a

sturdy base, mount directly on the valve

to align and center the unit. Two

different tool heads provide access to

any inside and outside diameter within

the standard 2.5 - 13 inch (63.5 - 330.2

mm) range.

Axial feed is via automatic power feed

(optional digital readout available). The

power feed unit can be quickly removed

if you want manual feed for tool

positioning. Automatic radial feed is

incorporated in both tool heads and

allows cutting of recesses and grooves.

The small tool head feeds the tool

radially at 0.0025 or 0.005 inches

(0.0635 or 0.1270 mm) per revolution.

Automatic tool stop allows cutting to a

preset diameter.

Setup and operation

To set up the VM6000, attach, center

and align the proper mounting fixture

components. Insert and center the

power head/spindle and align it in the

valve. Once the VM6000 has been

aligned it can be removed and replaced

without disturbing the alignment.

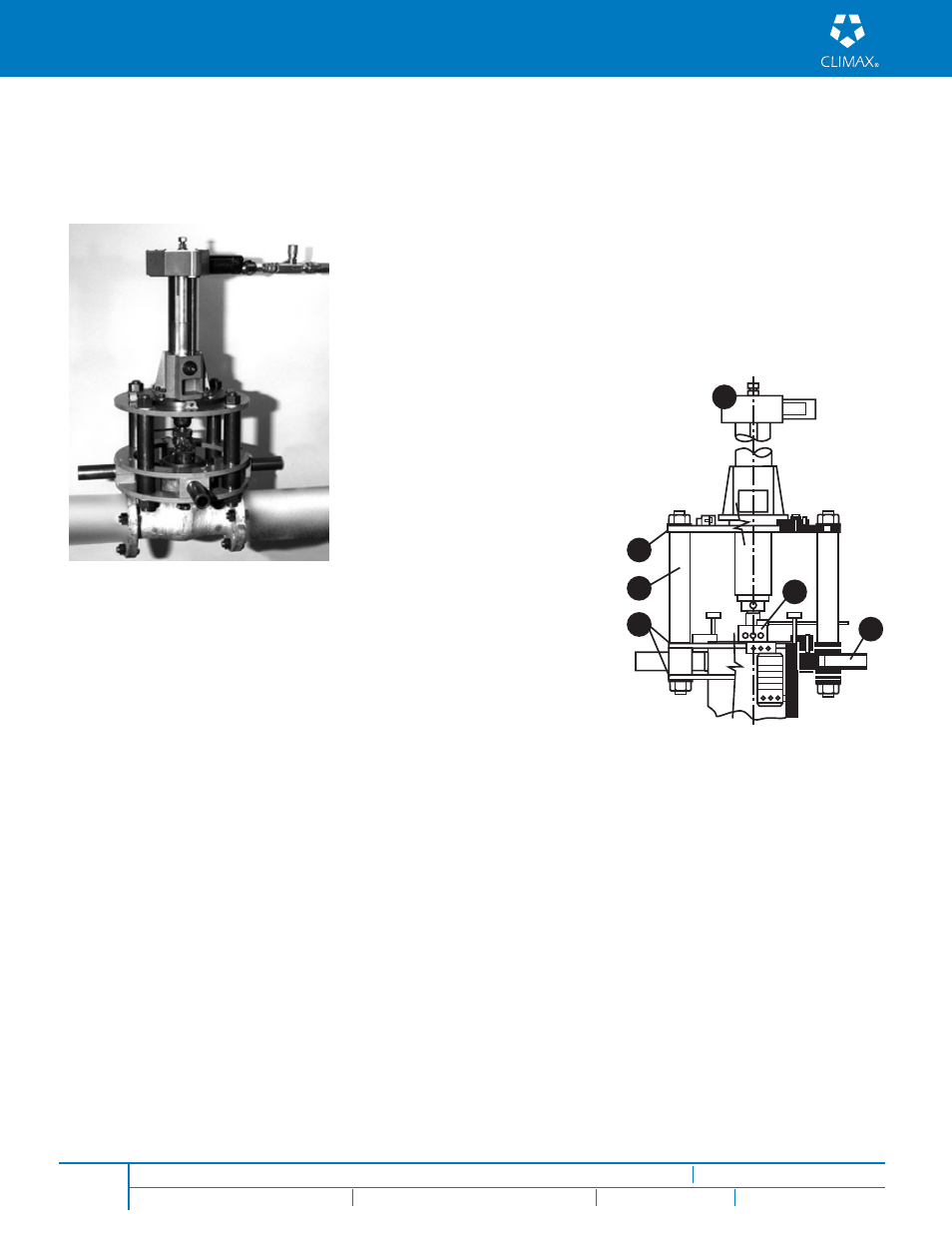

6

2

3

1

4

5

Repair n-Line Valves With 2.5 - 13 inch

(63.5 - 330.2 mm) Diameter Pressure Seal Bores

1. Valve clamping ring

2. Power head alignment

plate

3. Support leg

4. Automatic boring head

5. Clamping jaw

6. Power head