Line leak testing, Overview – Franklin Fueling Systems T5 Series Fuel Management System Operators Guide User Manual

Page 23

19

Line Leak Testing

Overview

Line Leak Detection is available only if the option for Line Testing is enabled. This option can be ordered when purchasing

the console or after the initial purchase by using the part number TS-ELLD. Relay, AC Input and 4-20mA Modules will also

need to be ordered and installed, if not initially purchased with the console. The TS-5 and TS-608 FMS consoles do not

have line leak detection capabilities.

Line Leak Testing for all T5 series FMS consoles use software rules to automatically run tests. Tests may be started

manually from the console or remotely using TSA. AutoLearn software monitors line conditions by conducting a multitude

of electronic line pressure sensing tests.

Line Leak Detection is required in many areas to monitor for potentially hazardous environmental contamination. In

the event of a leak, the system may provide positive pump shutdown (to prevent further contamination) and display an

indicator light and on-screen description of the condition as console alarm notifications. A high intensity remote alarm may

also be used if applicable. After installation, the user of the system must monitor the system to ensure that any leak alarm

and pump shutdown (indicating a line leak) is dealt with promptly.

The LS500 LLD system can detect a leak from the check valve in the pump to the solenoid valve at the dispenser —

assuming no other normally closed valve is in the pipeline system. This system does not detect leaks from the fuel storage

tank. The LS500 should be used in applications where site conditions are in accordance with Third Party testing (as listed

in the NWGLDE section of this chapter).

Terms

Piping Modulus – This is the maximum pipe capacity that may be tested in accordance with the 3

rd

Party Approval,

regardless of pipe diameter.

Transducer – An electronic pressure sensing device placed in the line that communicates with the console..

Certifications – 3

rd

Party Approvals

TS-LS500 AutoLearn Pressurized Electronic Line Leak Detection as of May 19

th

, 2006 has been approved by a third party

for leak detection of rigid and flexible piping.

National Work Group Leak Detection Evaluations (NWGLDE)

This data can be referenced on the abbreviated version of the 3

rd

Party Certification performed by Ken Wilcox Associates,

located on the NWGLDE site:

http://nwglde.org/

.

Line Leak Testing Requirements

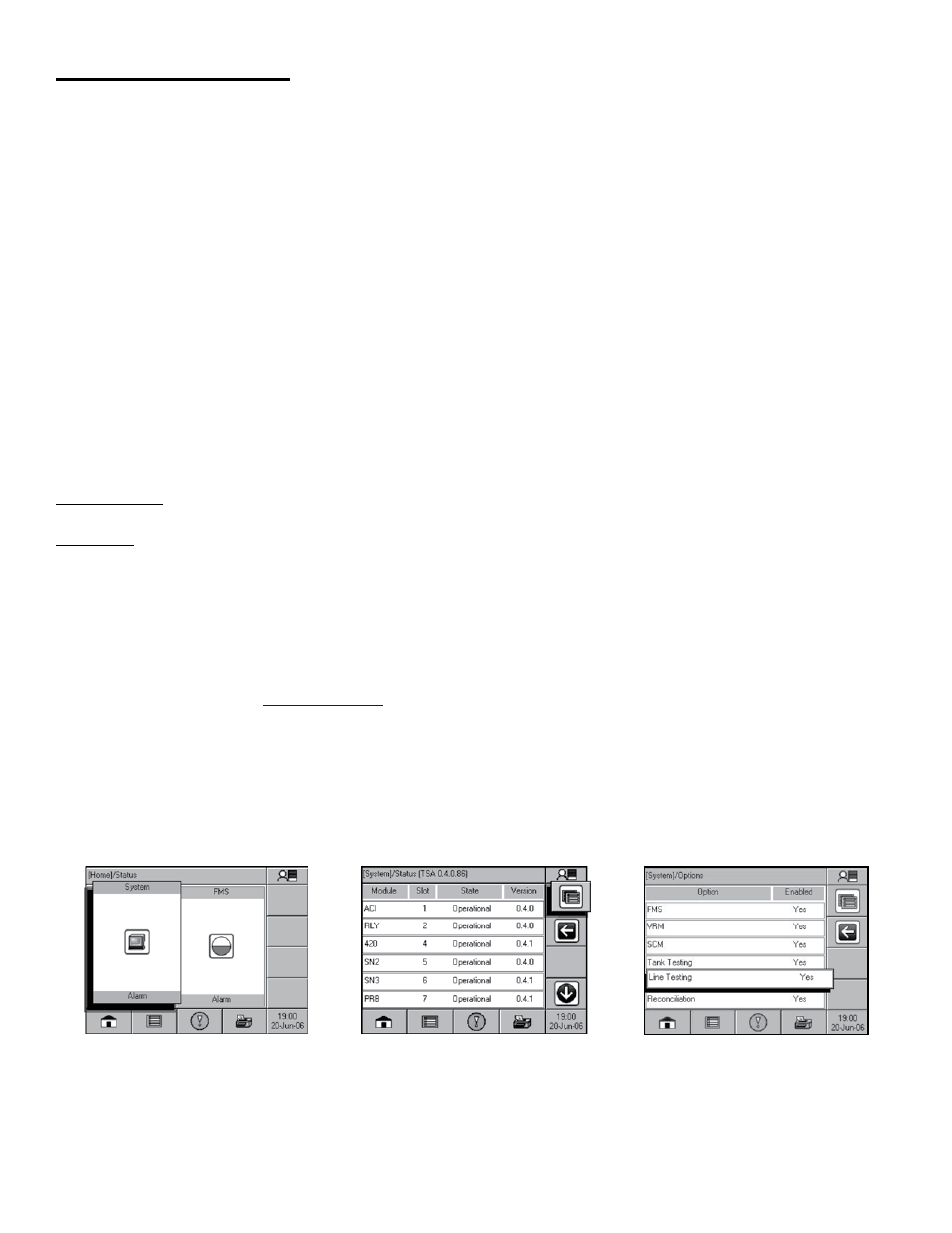

To perform Line Leak testing, the Line Leak software must be enabled. To verify that the Line Leak software is enabled:

Starting at the Home/Status screen, press the System Application button.

1.

Press the Application Menu button.

2.

Under Option, a Line Testing row will appear. A “Yes” in the Enabled column indicates that the software has been

3.

purchased and is enabled.

Step 1

Step 2

Step 3