2 operator troubleshooting, 1 operational defects – Armasight NSCCOMINI139DA1 CO-Mini GEN 3+ Alpha MG Night Vision Mini Clip-On System User Manual

Page 31

31

4.2 OPERATOR TROUBLESHOOTING

The purpose of troubleshooting is to identify the most commonly occurring equipment malfunctions,

their probable causes, and the corrective actions required to fix them.

Table 4-2 lists the common malfunctions that may occur during the operation or maintenance of the

CO-MINI. Perform the tests, inspections, and corrective actions in the order listed in the table.

This table cannot list all of the malfunctions that may occur with your CO-MINI, or all of the

tests and corrective actions that may be necessary. If you experience an equipment malfunction

that is not listed, or is not fixed by the corrective actions listed in the table, please contact Armasight’s

Customer Service center.

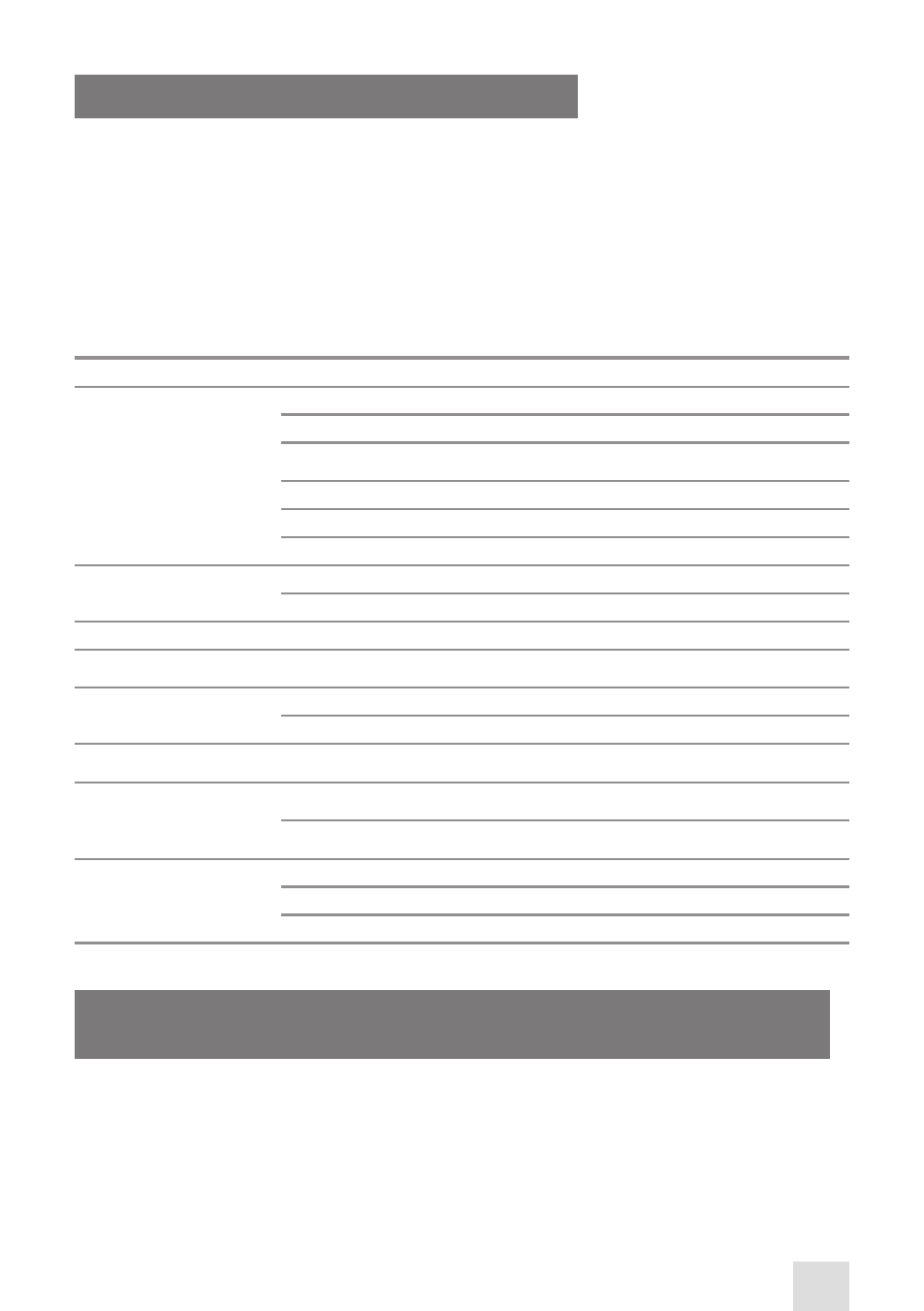

TABLE 4-2. OPERATOR TROUBLESHOOTING

MALFUNCTION

PROBABLE CAUSE/ TEST/INSPECTION

CORRECTIVE ACTION

CO-MINI fails to activate.

Battery is missing or improperly installed.

Insert battery or install correctly.

Battery is dead.

Replace the battery.

Battery surfaces or contacts are dirty or

corroded.

Clean the contact surfaces with a pencil eraser and/

or alcohol and cotton swabs.

Remote control unit is damaged.

Please contact Customer Support.

Remote control batteries are dead.

Replace the batteries as per Part 4.4.3.

Defective image intensifier.

Please contact Customer Support.

Poor image quality.

Objective and output lenses are dirty.

Thoroughly clean the surfaces of each lens.

Damaged optical components.

Please contact Customer Support.

LED indicator fails to activate.

Visual inspection.

Please contact Customer Support.

CO-MINI affects boresight after

installation or during the firing.

Factory alignment is broken.

Please contact Customer Support.

Hindered rotation of the battery

cap.

Dirty cap thread.

Clean the thread.

Damaged cap thread.

Please contact Customer Support.

Battery adapter difficult to remove. Check for damaged battery adapter and

battery cap.

If damaged please contact Customer Support.

Light visible around light sup-

pressor.

Incorrect position of the CO-MINI relative to

the day scope.

Align the CO-MINI position relative to the day scope.

Check the light suppressor resilience.

If light suppressor is defective please contact

Customer Support.

IR850 fails to activate.

Battery is missing or improperly installed.

Insert battery or install it correctly.

Battery is dead.

Replace the battery.

IR850 damaged.

Please contact Customer Support.

4.3 INSPECTION CRITERIA FOR PROPER IMAGE INTENSIFIER

TUBE OPERATION

4.3.1 OPERATIONAL DEFECTS

Operational defects relate to the reliability of the intensifier, and are an indication of instability. If iden-

tified, the user will need to return the CO-MINI immediately. Operational defects include shading, edge

glow, flashing, flickering, and intermittent operation.

- NSCCOMINI1P9DA1 CO-Mini GEN 3P MG Night Vision Mini Clip-On System NSCCOMINI1G9DA1 CO-Mini GEN 3 Ghost MG Day/night vision Clip-On system Standart Definition NSCCOMINI1F9DA1 CO-Mini Flag MG Day/night vision Clip-On system Standart Definition NSCCOMINI139DB1 CO-Mini GEN 3 Bravo MG Night Vision Mini Clip-On System NSCCOMINI129DI1 CO-Mini GEN 2+ ID MG Day/night vision Clip-On system Improved Definition NSCCOMINI129DH1 CO-Mini GEN 2+ HD MG Day/night vision Clip-On system NSCCOMINI1Q9DI1 CO-Mini GEN 2+ QS MG Day/night vision Clip-On system