Af-600 fp high power operating instructions – GE Industrial Solutions AF-600 FP Fan and Pump Drive (460V_575V 150HP and above) User Manual

Page 13

Screening of cables:

Avoid installation with twisted screen ends (pigtails). They spoil the screening effect at higher frequencies. If it is necessary to break the screen to install a motor

isolator or motor contactor, the screen must be continued at the lowest possible HF impedance.

Connect the motor cable screen to both the de-coupling plate of the frequency converter and to the metal housing of the motor.

Make the screen connections with the largest possible surface area (cable clamp). This is done by using the supplied installation devices within the frequency

converter.

Cable-length and cross-section:

The frequency converter has been EMC tested with a given length of cable. Keep the motor cable as short as possible to reduce the noise level and leakage

currents.

Switching frequency:

When frequency converters are used together with Sine-wave filters to reduce the acoustic noise from a motor, the switching frequency must be set according

to the instruction in par. F-26 Motor Noise (Carrier Freq).

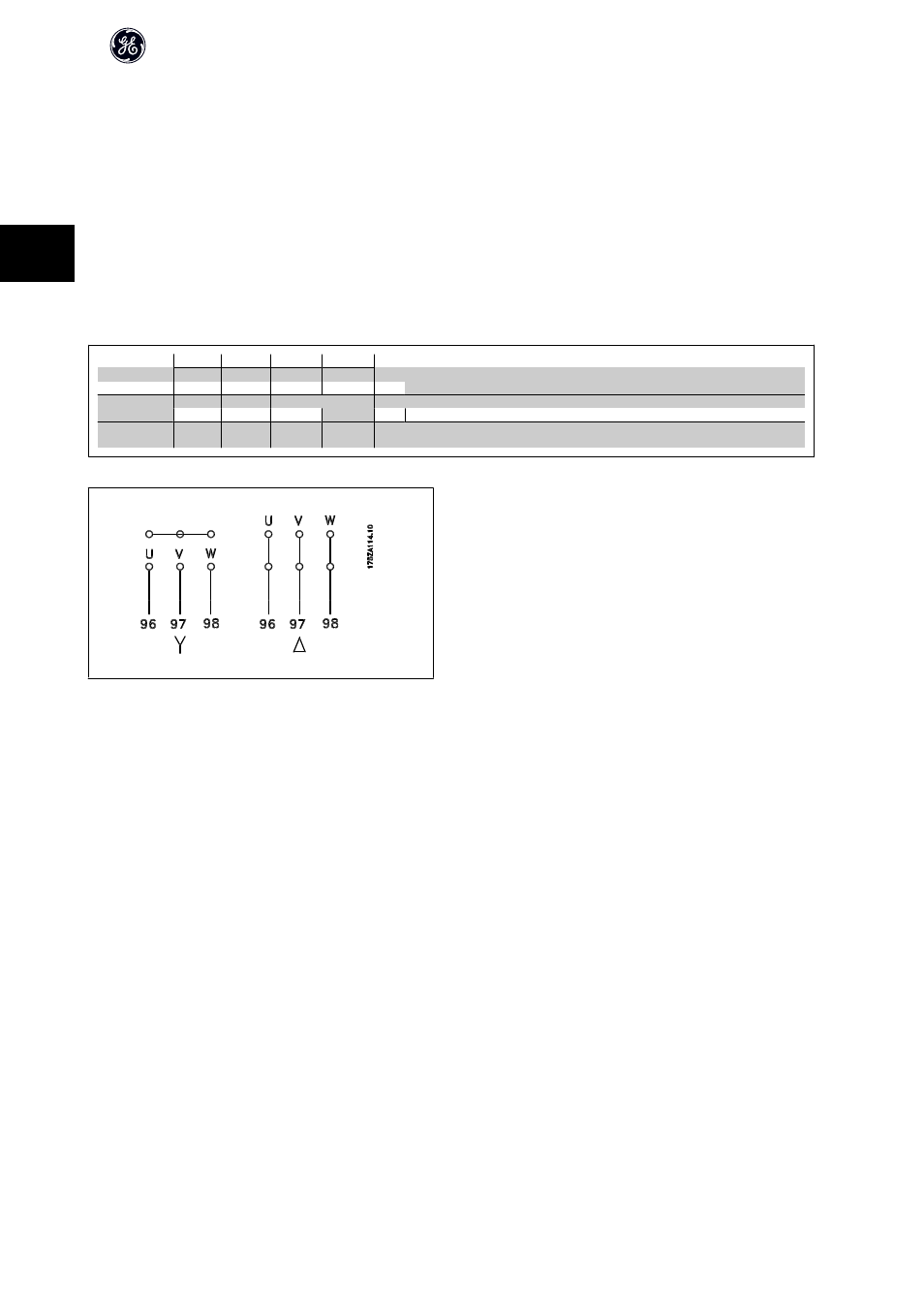

Term. no.

96

97

98

99

U

V

W

PE

1)

Motor voltage 0-100% of mains voltage.

3 wires out of motor

U1

V1

W1

PE

1)

Delta-connected

W2

U2

V2

6 wires out of motor

U1

V1

W1

PE

1)

Star-connected U2, V2, W2

U2, V2 and W2 to be interconnected separately.

1)

Protected Earth Connection

AF-600 FP High Power Operating Instructions

12

3