Installation, 6. thyristor check – GE Industrial Solutions ASTAT-CD Plus User Manual

Page 28

Symptom or Error & (Error Code)

Possible Cause

Measures to be taken

Synchronism loss

(Ex13)

Phase A, B, C thyristor

(Ex14)

(Ex15)

(Ex16)

Heatsink thermostat

(Ex17)

Motor thermistor

(Ex18)

Phase A, B, C loss

(Ex19)

(Ex20)

(Ex21)

Stalled rotor

(Ex22)

Check 1L1 phase

Check thyristor module

Check ground connections and voltage to ground

Poor ribbon cable connection

Check 2T1, 4T2 and 6T3 phases

No output phases

Short circuited thyristor

Phase 1L1 lost

Check for adequate ventilation

Check thermostat and wiring

Heatsink thermostat tripped by overheating or

defective

Check thermistor and wiring, if no thermistor

terminal 5 and 6 must be jumpered

Motor thermistor tripped by overheating or defective

Check power wire harness for 1L1, 3L2, 5L3,

2T1, 4T2 and 6T3

No input / output phases

Verify gate and cathode wire

harness. Verify thyristors

Defective thyristor or ribbon wire harness

loose or defective

Restart equipment and check for an appreciable loss in

motor speed at any time

Equipment detected stalled motor rotor

Internal error

(Ex23)

Long start time

(Ex25)

Long slow speed time

(Ex26)

Reduce time slow speed is engaged

Equipment has been in slow speed mode more

than 120 sec.

Check IC1 and IC8 are correctly inserted in their sockets.

Check for noise on control voltage power or line

Micro-controller malfunction

Increase current limit and / or acceleration

ramp time

Current limit condition present more than

2 x ta sec. or 240 sec.

(ta = acceleration ramp time)

5. Installation

L

S

10 ohms

3 to 6V

3 to 6V

Testing

lamp

1L1 (3L2 or 5L3)

2T1 (4T2 or 6T3)

5-4

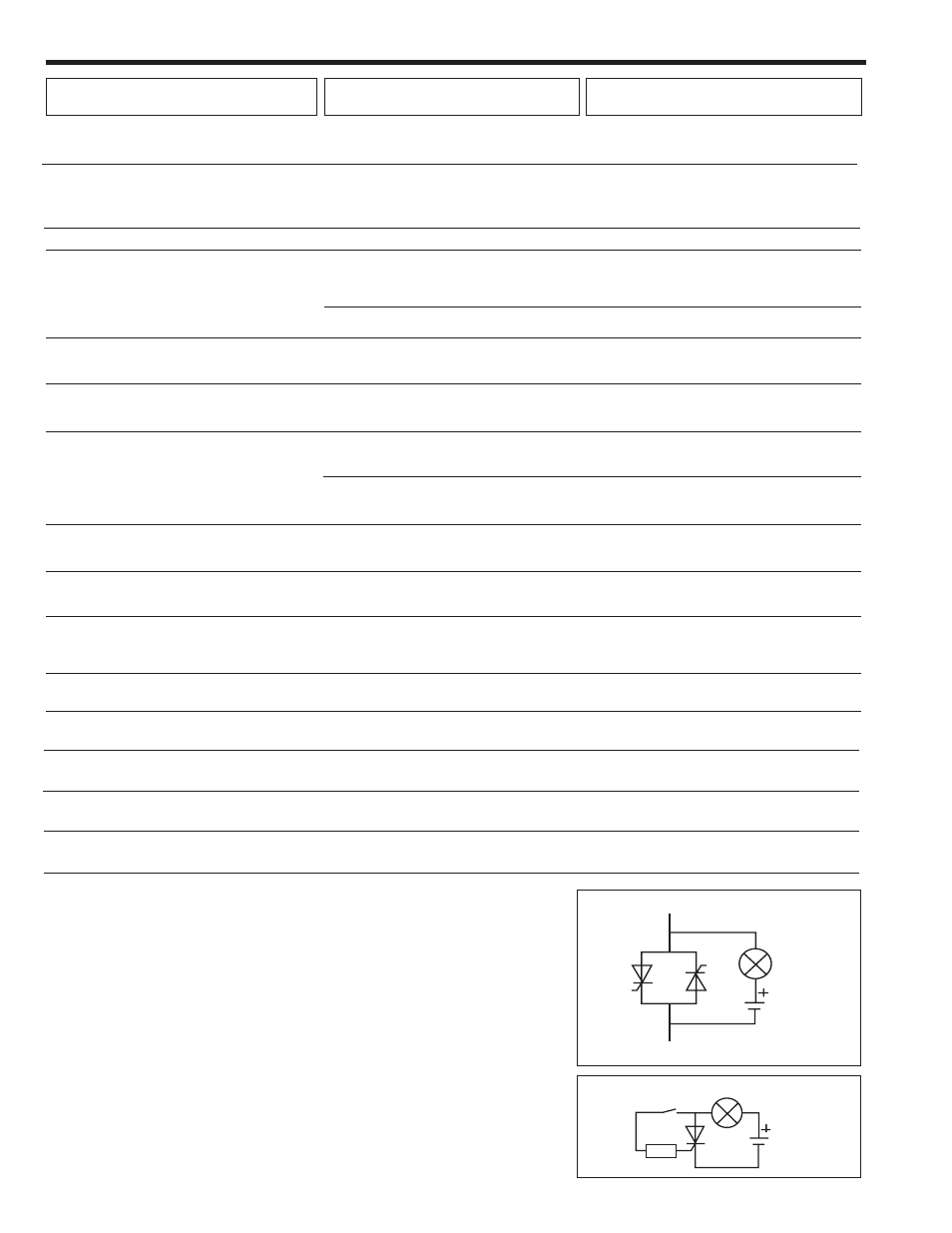

5-6. Thyristor check

S

hortcircuit

Use a testing lamp to check the defective power module between input and output phases.

If the lamp goes on, at least one of the thyristors has a short circuit.

With a tester, check the value or the R resistance between input and output of the same phase

(connector B on main PCB must be previously removed).

If R < 50K

Ω

, at least one of the thyristors is defective.

Open thyristor

With the simple assembly shown, the lamp should light when the S switch is closed and remain lit when open.

If not, the thyristor is defective.

Lock-out

(Ex27)

Check if settings are correct

This protection may be disabled

The time between startings is less that the

adjusted in parameter "LKxx"

Undervoltage

(Ex28)

Overvoltage

(Ex29)

Check if settings are correct.

This protection may be disabled

The line voltage exceeds of limit set in

parameters "UVxx" or "OVxx"

Undercurrent

(Ex30)

Overcurrent

(Ex31)

Check if settings are correct.

This protection may be disabled

The motor current exceeds of limit set in

parameters "UCxx" or "OCxx"

Retry

(Ex32)

Check last message "e1xx" and correct.

Be sure that retry settings are correct as well.

The retry feature could not re-start the motor

after a fault

Excessive load or excessive current during

starting

Verify overload conditions during starting time and

steady state.

Check settings in parameters "Nxxx", "Lxxx", and "oxxx"

Overload trip

(Ex11)

Check 1L1 phase and/or mains frequence

No 1L1 phase or frequence is out of range

Frequency error

(Ex10)

(admits 45Hz

≤

f main

≤

65Hz)