Baron Air & Fuel_NEEDLE_JET KIT V-Star1100 Classic_Custom User Manual

Page 2

Page: 2

BA-2440VS

NEEDLE/JET KIT - Yamaha V-Star 1100 Custom & Classic

(99-10)

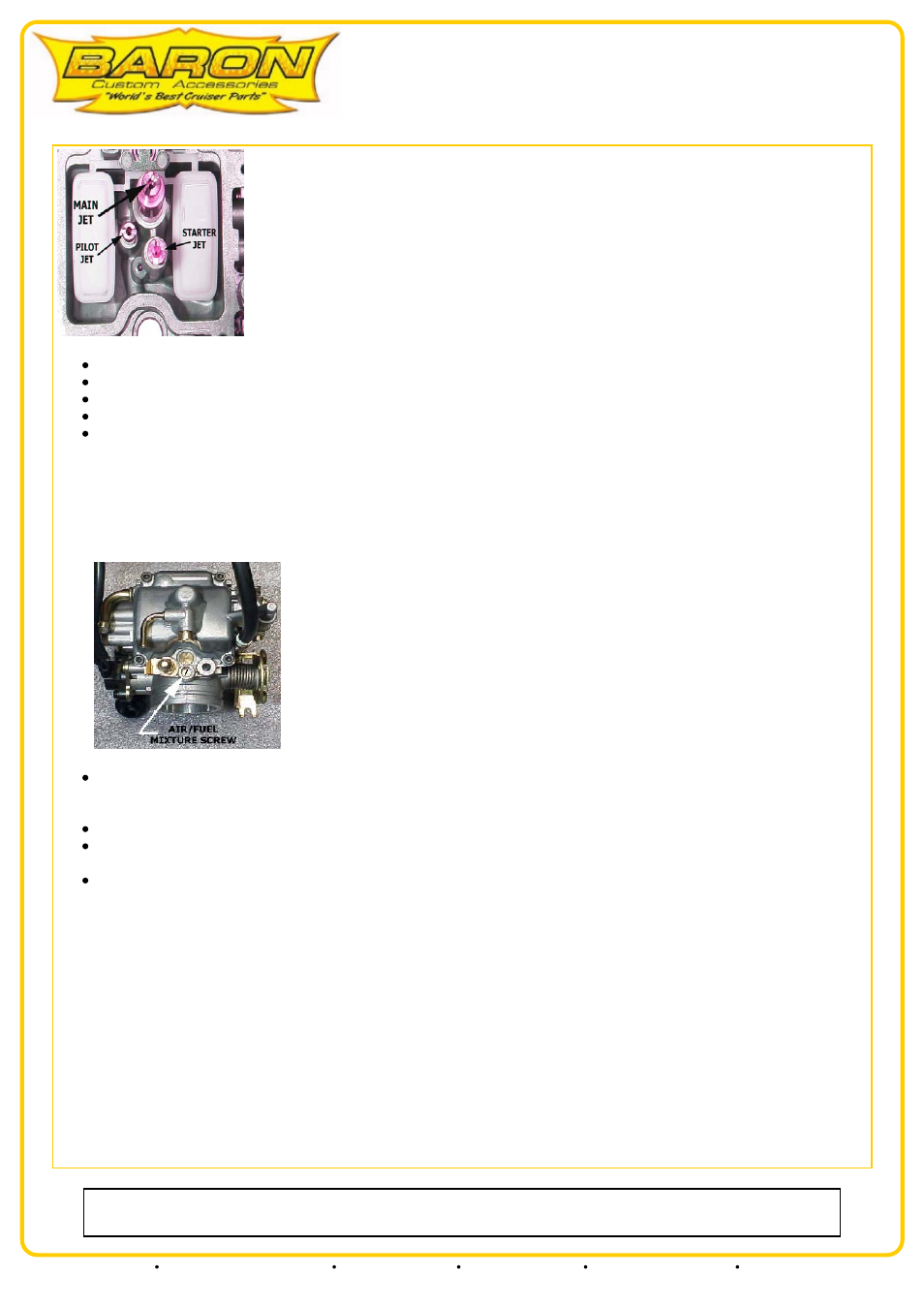

USE THE FOLLOWING MAIN JETS AS INDICATED BELOW:

Stock Air Filter/Pipes: 112.5 F 110 R

Aftermarket Filter/Pipes: 115 F 112.5 R

F=Front cylinder, R=Rear cylinder

High altitude above 5000 applications may require the use of one size smaller/leaner jets.

All 1100's use the richer Pilot Jets supplied in the kit.

9. Thoroughly clean the inside of the float bowls prior to reinstalling them.

10. Reassemble the carburetors by reversing the order of step #1 through step #9. Use the new supplied cap head allen screws in

place of the OEM Phillips head screws for the float bowls.

11. Locate the air/fuel mixture screw in each carb. You will see either a screw head or a brass plug.

If it is a screw head, skip to step #11c. If you see a brass plug with a small hole in the center, proceed as follows:

With a 5/32" drill bit, carefully and slowly drill through the fuel mixture plugs.

CAUTION! The fuel mixture screw is directly under this plug. Be prepared to stop the drill the INSTANT you break through the

plug or you may destroy the screw.

Insert a self-tapping sheet metal screw into the drilled hole and remove the plugs.

With air/fuel screw now accessible, use a flat blade screwdriver to turn the screw clockwise until it lightly seats, then carefully turn it

counter-clockwise 4 turns.

Refer to step #16 for assistance in fine-tuning the setting of the air/fuel adjustment screw. Do this to both carburetors. 12. Reinstall

the carburetors.

13. Reconnect the fuel lines, ensuring the clamps are firmly in place.

14. Reinstall all vent hoses and electrical connectors that were previously removed, checking for any obstructions or blockage.

15. Reinstall the OEM air filter assembly or, if you are installing our Big Air Kit (BAK), follow the instructions that accompany that

kit and then continue with step #16.

16. Verify proper throttle operation before starting the vehicle. Make sure the cables are not binding.

17. The adjusting procedure requires the use of carburetor sticks or a set of vacuum gauges. The carburetors must be synchronized

in order to achieve optimum performance. This procedure should be performed by a qualified Yamaha repair technician. Verify that

the air/fuel adjustment screw has been set to a starting position as described in step #11c, and that the clip has been installed as

detailed in step #4. Check the engine at idle speed for any popping or back firing. For best results, we recommend the air/fuel

mixtures be adjusted with an Exhaust Gas Analyzer (EGA) to a CO reading between 2% and 3%.

Our install guides provide a basic outline on the proper installation of our products. Further tuning and/or

fitment may be required. Barons bears no responsibility on installation costs associated with this product.

© 2013 Barons Custom Accessories

5221 Oceanus Drive

Huntington Beach, CA 92649

(925)583-2499 - Ph.

(714)901-0520 - Fax

www.baronscustom.com