Ab b, Installation guide, Data output – Veris Industries E30 Install User Manual

Page 3: Blink codes for status led, Solid-core current sensor accuracy, Product diagram

Z204998-0N

PAGE 3

©2013 Veris Industries USA 800.354.8556 or +1.503.598.4564 / [email protected]

01131

TM

E30

INSTALLATION GUIDE

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

DATA OUTPUT

Monitoring at Mains

E30A

E30B

E30C

Current per phase

Max. current per phase

Current demand per phase

Max. current demand per phase

Energy (kWh) per phase

Real Power (kW) per phase

Apparent Power (kVA)

Power factor total *

Power factor per phase

Voltage - L-L and average

Voltage - L-N and average

Frequency (phase A)

Monitoring at Branch Circuit

Current

Max. current

Current demand

Max. current demand

Real power (kW)

Real power (kW) demand

Real power (kW) demand max.

Energy (kWh) per circuit

Power factor

Apparent Power (kVA)

Modbus Alarms

Voltage over/under

Current over/under

* Based on a 3-phase breaker rotation.

BLINK CODES FOR STATUS LED

Color and Pattern

Status Description

Green, once per second

Normal operation

Amber, once per second

Volts or Amps clipping

Amber, twice per second

Invalid firmware image

Amber, three per second

Incorrect strips or strip order

Red, solid or blink

Diagnostic event detected

SOLID-CORE CURRENT SENSOR ACCURACY

100A Solid-Core CT

Voltage Rating

300 VAC

Accuracy

±0.5%

Temperature

0° to 60°C

Agency

UL508 recognized, EN61010

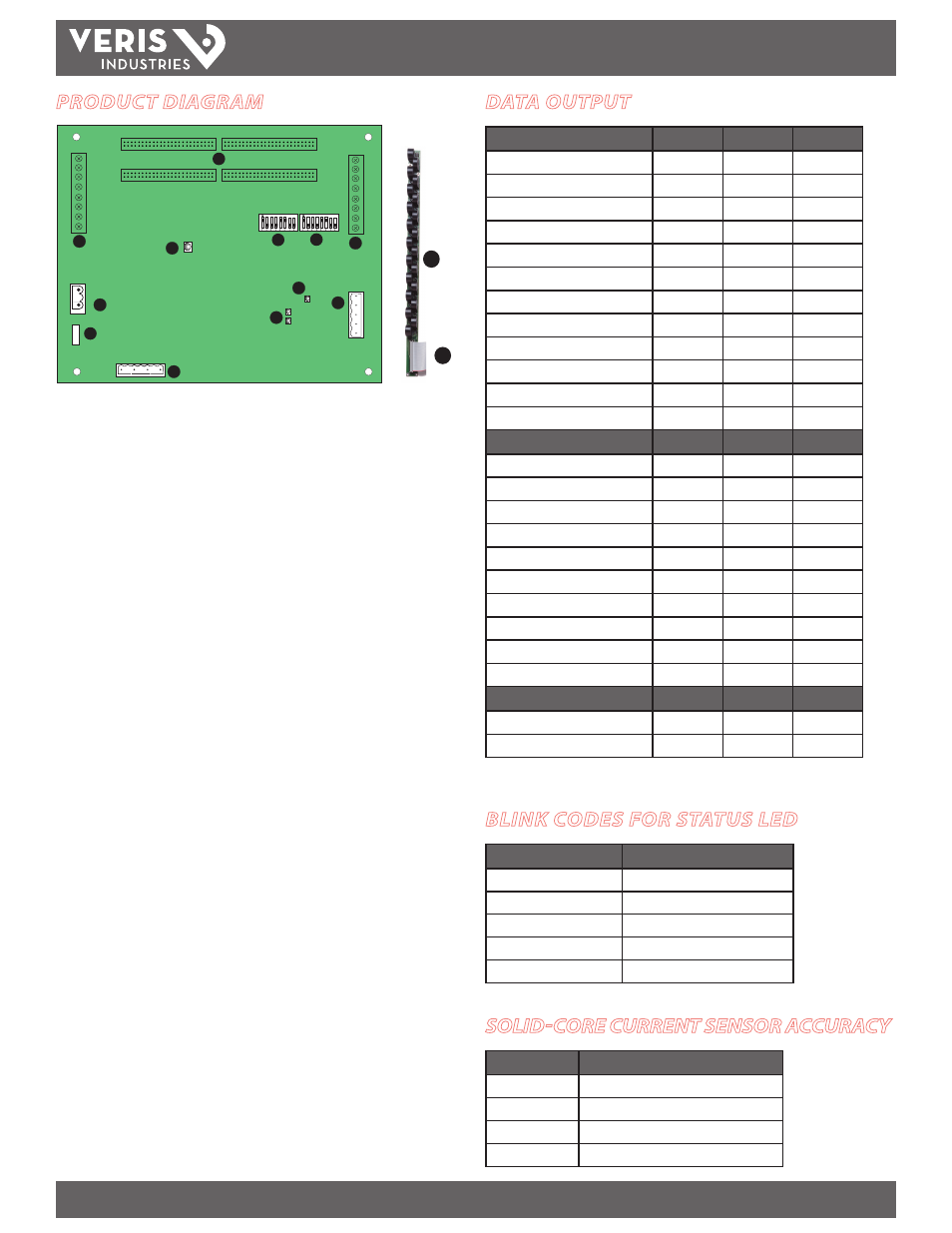

PRODUCT DIAGRAM

7

1

2

3

4

5

6

2

8

9

10

A

A

B

B

11

1.

50-Pin Ribbon Cable Connectors (Data Acquisition Board):

48-inch (1220

mm) ribbon cables are provided for easy connection of current sensor strips to

this point of the data acquisition board. The two connectors on the left are for

panelboard 1; the two on the right are for panelboard 2.

Connect current sensor strips to the correct ribbon cable connectors for each

panel. The top connector is for Strip A, and the bottom conector is for Strip B.

Verify that the serial numbers on the current sensor strips match the

serial number on the data acquisition board.

2.

Auxiliary Inputs:

These 0.333 VAC inputs are used for monitoring the main

breaker or other high amperage source. Inputs on the left are for panelboard 1;

inputs on the right are for panelboard 2.

3.

Control (Mains) Power Connection:

Easy 2-wire 90-277 VAC 50/60 Hz

connection.

4.

Control Power Fuse:

600 VAC, 500 mA time lag, factory-replaceable.

5.

Alive LED:

Red/green/amber LEDs. Blink codes are on page 3.

6.

Voltage Taps:

1, 2, or 3 phase plus neutral connections. For voltage sensing and

power calculations (no voltage taps on the E30C).

7.

Communications Address DIP Switches:

Each Modbus device must have a

unique address. Switches are binary weighted. Left-most switch has a value of 1;

right-most switch has a value of 128. Note: the 4-strip model uses 2 addresses.

8.

Communications Settings DIP Switch:

Configures baud rate, parity, 2/4 wire

communications.

9.

RS-485 2 Connection:

Used for Modbus serial communications. The Universal

plug accomodates 2 or 4 wire connections.

10.

RS-485 LEDs:

The RX LED (closest to DIP switches) indicates the RS-485

is receiving information; the TX LED (farthest from DIP switches) indicates

transmission of information.

11.

Power LED:

Indicates power to main board

12.

Current Sensors:

Each current sensor is capable of monitoring conductors rated

up to a maximum of 100 amps.

13.

50 Pin Ribbon Cable Connectors (Current Sensor Strips):

Connects current

signal from the sensor strip to the main board via the ribbon connectors.

12

13