Veris Technologies MSP EC and pH (1997-2008 CF card drive 1.10M) - Operating Instructions User Manual

Page 40

Veris Technologies

Pub. #OM MSP03-1

40

Maintenance and Lubrication

• Pinch point hazard: to prevent injury, stand clear when raising or lowering any part of the Veris

MSP. Disengage automatic cycling function before working around unit. Install all transport locks

before transporting or working underneath.

Lubrication

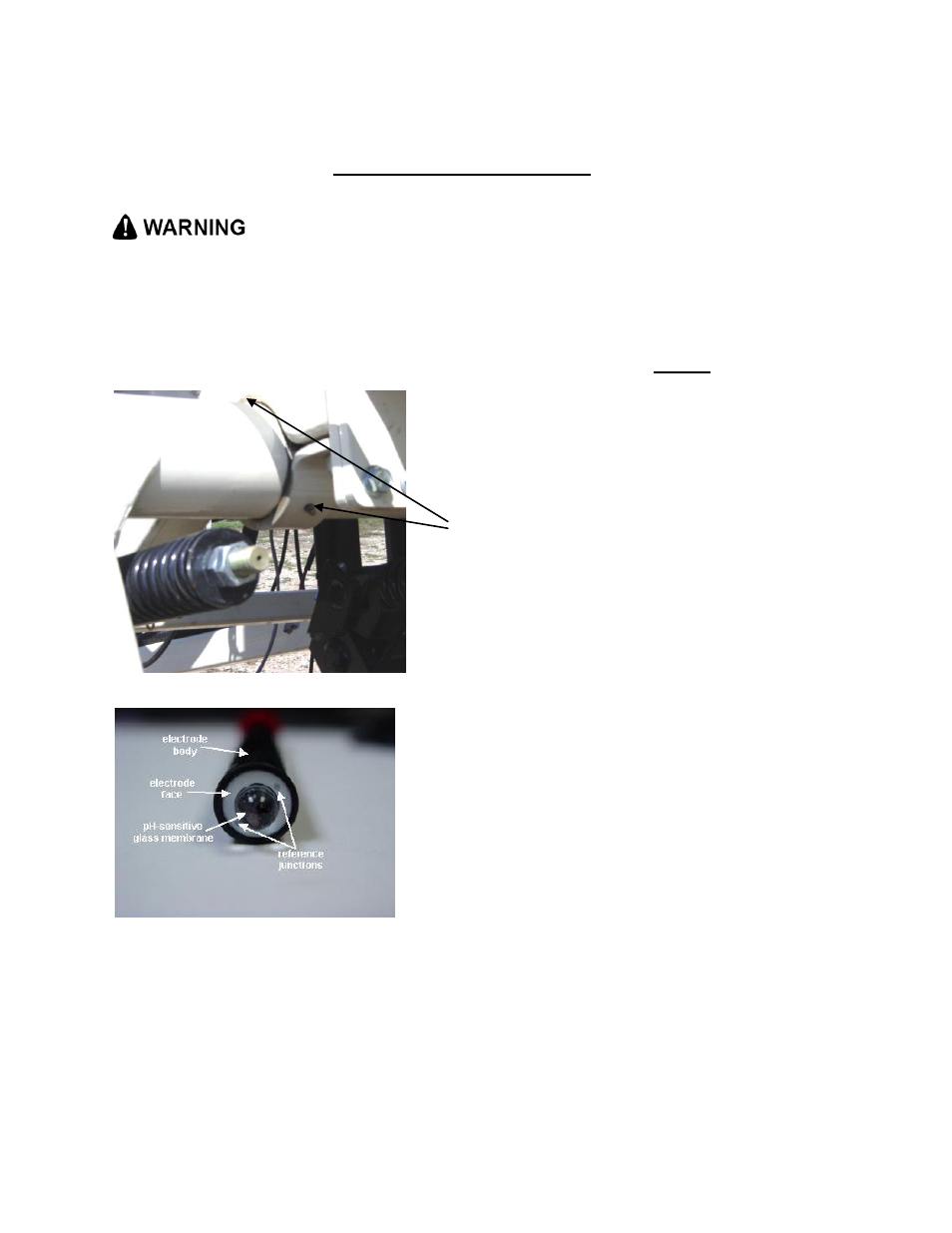

Rockshaft pivot points

– Each pivot (located at the left and right) contains an upper and lower grease

zerk. Due to the limited motion of the rockshaft, these should be lubricated on 20-hour intervals.

This may vary based on the number of times the unit is raised and lowered.

pH Electrodes

-always use proper soaker solution: Veris part #23395

-Completely wash clean after each field: face, glass, lower body that is in soaker solution

-do not touch bulb with skin

-Keep moist; put in soaker solution if mapping (washing) is interrupted for 15 minutes

-Replace soaker solution every week or more frequently if it gets diluted with tap water or dirty

-If soaker solutions is unavailable use pH buffer 4; never soak in distilled or de-ionized water

-remove from holder and place in individual soaker bottles in freezing temperatures and when unit will

be idle for long periods

-calibrate daily and maintain calibration logs

-keep cover over BNC ports on external controller whether electrodes are attached or unattached

Pivot grease zerks (2 per hangar;

4 total)