Veris Technologies MSP EC and pH (1997-2008 CF card drive 1.10M) - Operating Instructions User Manual

Page 17

Veris Technologies

Pub. #OM MSP03-1

17

the commutators should be checked. This may be performed in the following

manner:

1)

Remove the 3/8” allen head set screw.

2) Remove the commutator by turning counter-clockwise.

3) Depress the spring loaded tip on a hard surface to determine if

plunger has adequate tension and can move freely.

4) If the plunger will not move freely, replace, and coat with di-electric

silicone grease.

5) If the commutator appears to be in good working order, reinstall in the

hub, and adjust until it bottoms against the spindle end. Rotate 1/2 turn

backward to allow adequate clearance. Improper adjustment will result in

premature failure (too little tolerance) or poor continuity (too much

tolerance).

6) Reinstall locking set screw and tighten firmly on top of commutator. The

top of the set screw should be even with the face of the hub. If not,

remove and adjust the commutator inward or outward as necessary.

7) Re-test coulter electrode continuity.

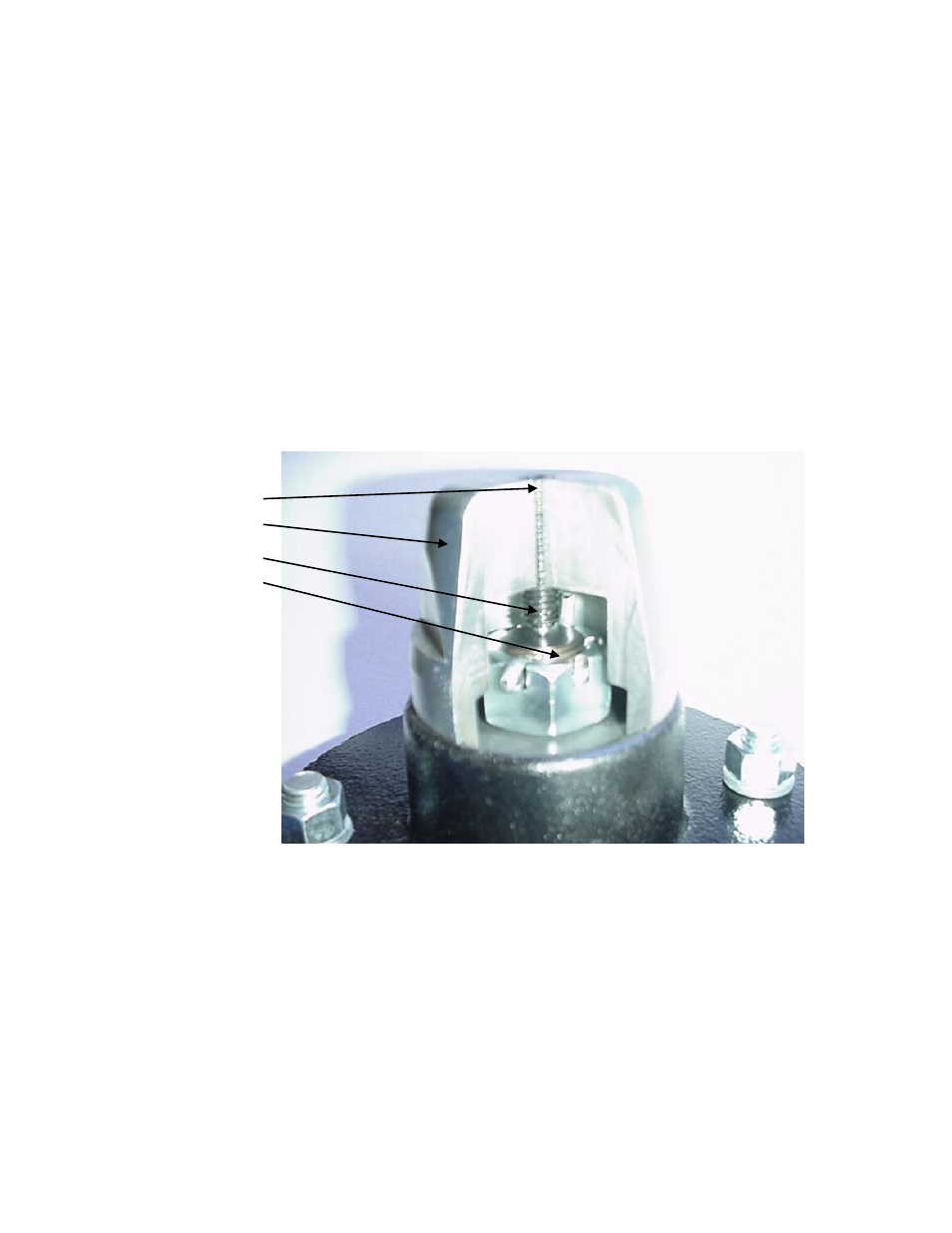

Here is a cut away view of the hubcap assembly:

Note: If you are still unable to obtain favorable resistance readings, check for

excessive corrosion at the coulter blade mounting bolts, or the terminal located

near the coulter pivot. It may be necessary to grind the spindle end smooth, if a

dimple has developed.

MAINTENACE: LUBRICATION

Rockshaft pivot points

–

Each pivot (located at the left and right) contains

cap

commutator

set screw

spindle