Veris Technologies MSP EC and pH (1997-2008 CF card drive 1.10M) - Operating Instructions User Manual

Page 12

Veris Technologies

Pub. #OM MSP03-1

12

• Escaping fluid under pressure can penetrate the skin causing serious injury. Avoid the hazard by

relieving pressure before disconnecting hydraulic lines. Use a piece of paper or card-board, NOT

BODY PARTS, to check for suspected leaks.

• Wear protective gloves and safety glasses or goggles when working with hydraulic and high-

pressure wash systems.

• If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

Field Operations

—Soil EC Surveyor

Checking Electrical Signal Continuity and Electrode Isolation

It is recommended that you routinely check the EC signal to verify that all functions are working

properly. See Maintenance and Lubrication Section for a step-by-step procedure. It is advisable to

perform this test on a routine basis (weekly or every 20-25 hours of data collection) to ensure you are

obtaining reliable data.

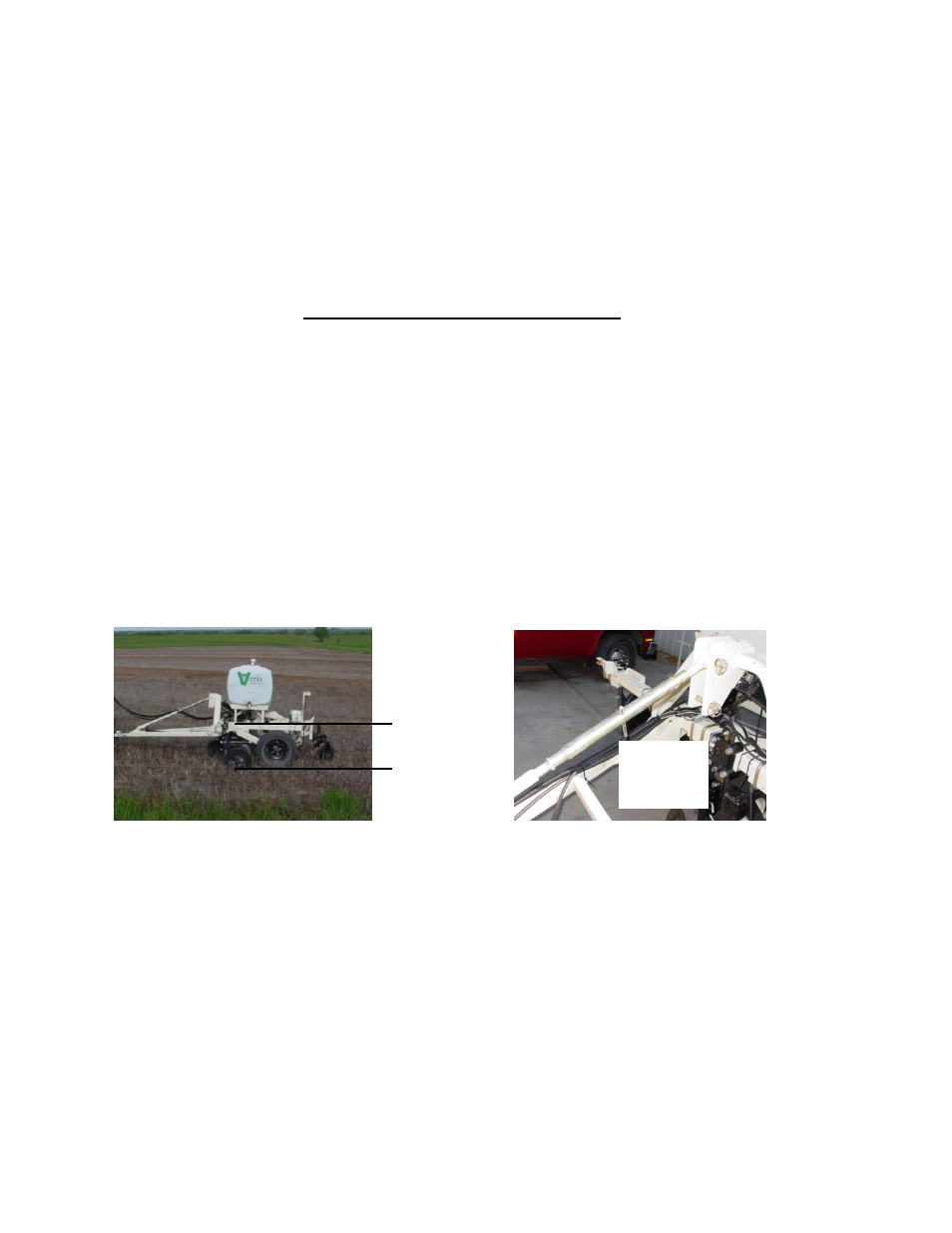

Setting Operating Depth

Begin field operation by lowering unit into soil. For good electrical conductivity, all coulter electrodes

must be in direct contact with the soil, at all times and in every region of the field. A depth of 1-

2”

(2.5-5 cm) is recommended. To insure this depth is consistently achieved, 400-600 lbs. (180-275 kg)

of additional weight are normally required. Veris offers optional weights, or they can be supplied by

the customer. If the unit is equipped with the pH module, keeping 40-60 gallons (225-350 L) of water

in the tanks provides ballast. Do not adjust the tension on the coulter electrode springs to increase

soil contact or penetration. They are pre-set at the factory with the proper tension. If unit is equipped

with pH module, it is especially important to keep the implement level during field operation. Adjust

top link to level.

Field Condition

Field should be in a uniform state. Mapping after intensive primary tillage is not recommended. The

soil must have a minimum of 10% available water, and cannot be frozen. If rocky conditions exist, you

may wish to consider the optional coulter rock guard kit , PN 15169.

Speed

Proper field operating speed depends on field conditions. Because of the importance of consistent

contact, the unit must not be allowed to bounce over rough fields at high speeds. On smooth fields,

the implement can be operated at speeds from 8-12 m.p.h. (12-18 km/hr)

Pulling Vehicle

The implement may be pulled with a variety of vehicles: 20-50 hp tractor, 4WD pickup or Jeep.

Swath width and Navigation

Setting the swath width and navigation system is at the discretion of the customer. A 40-

60’ (12-18

m) swath works well in most areas. In areas of high soil variability, a narrower swath may be

preferred. Several methods of navigation are possible: following previous crop rows, swath guidance,

o

r using a field navigation computer. While it is important to map in a consistent pattern, it isn’t

absolutely critical that each pass be exactly the same distance from the previous pass.

operate

implement

parallel to

soil

adjust

toplink to

level