Technical data – M&C TechGroup EC-Ex Data sheet User Manual

Page 3

M&C TechGroup Germany GmbH • Rehhecke 79 • 40885 Ratingen • Germany

[email protected] • www.mc-techgroup.com • Fon +49 2102 935-0 • Fax +49 2102 935-111

6.5

Technical specifications and illustrations are without

obligation, subject to modifications. 10.96/09.09

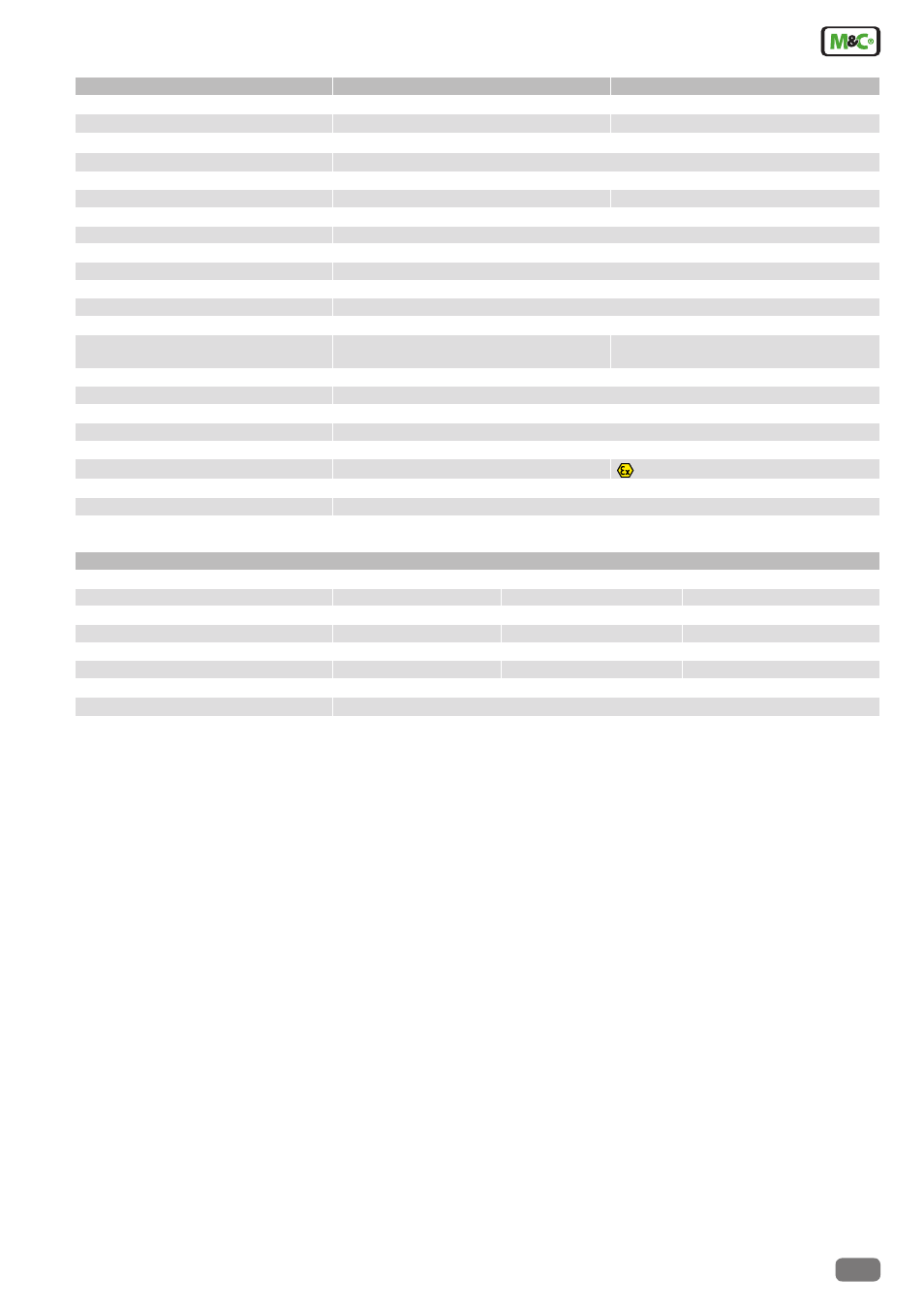

Gas Cooler Series EC®

ECS

EC-Ex

Part number with glass heat exchanger

02 K 1500 (a)

02 K 5000 (a)

Part number with stainl. steel heat exchanger

02 K 2500 (a)

02 K 5010 (a)

Part number with PVDF heat exchanger

02 K 3500 (a)

02 K 5020 (a)

Number of heat exchanger

1 optional to 4

Gas flow rate per heat exchange

250 Nl/h**

Ambient temperature

+5 to +45 °C, with option EC-F = +5 to +50 °C

+5 to 45 °C

Storage temperature

-20 to +60 °C

Sample outlet dew point

range of adjustment: +2 °C ..... +7 °C, factory setting: +5 °C

Dew point stability

at constant conditions ±0,25 °C

Sample inlet temperature

max. 180 °C**

Sample inlet dew point

max. 80 °C**

Total cooling power

max. 520 KJ/h at 25° C ambient temperature

Power consumption

280VA, Start up current at 230V= 7,9A

Main connection

230V ±10%, 50Hz,

optional 115V ±10%, 60Hz

230V ±10%, 50Hz,

optional 115V ±10%, 50-60Hz

Ready for working

< 30 min.

Electrical connection

2,5 mm

2

terminals

Status alarm: ECS 2 changeover contacts

Contact rating: 250V, 2A, 500VA, 50W, Alarm point: ∆T ±3 °C zu Tsoll

Status alarm: EC-Ex 1 changeover contact

Contact rating: 220V, 2A, 100VA, 50W, Alarm point: ∆T ±3 °C zu Tsoll

Case protection

IP 20; EN 60529

Electrical standard

EN 61010

II2G EEx p, e, d, q, (ib) IIC T4

Case color

RAL 9003

Method of mounting

19’’ rack- or wallmounting

Dimension / Weight

84HP x 7U x 360 mm / 31 kg

84HP x 7U x 450 mm / 40 kg

Technical Data

* Optional

** Maximum values in technical datas must be rated in consideration of total cooling capacity at 25 °C ambient temperature and an outlet dew point of 5 °C.

1) Others on request.

2) With GL-Anschlussadapter.

3) With SR25.1 max. 2 bar abs.

(a) Addition to part number for 115V execution

GL adapter and tube fittings for the connection of differerent tube diameters at the heat exchanger see chapter 11, data sheet 11.5 and 11.6.

Options

Heatexchangerexecution

Material of heat exchanger

Borosilicate glass

PVDF

stainless steel 316Ti

Part number

02 K 9100

02 K 9300

02 K 9200

Admissible gas pressure bar g

3

2)

/ 2

3)

3 / 2

3)

10 bar

Sample gas connection

GL18-6 ø6 mm 8 o. 10 mm*

G 1/4’’ i

G 1/4’’ i NPT*

Condensate connection

GL25-12 ø12 mm 10 o. 8 mm*

G 3/8’’ i

G 3/8“ i NPT*

∆P per heat exchanger at 300 l/h

1 mbar

Dead volume per heat exchanger

70 ml