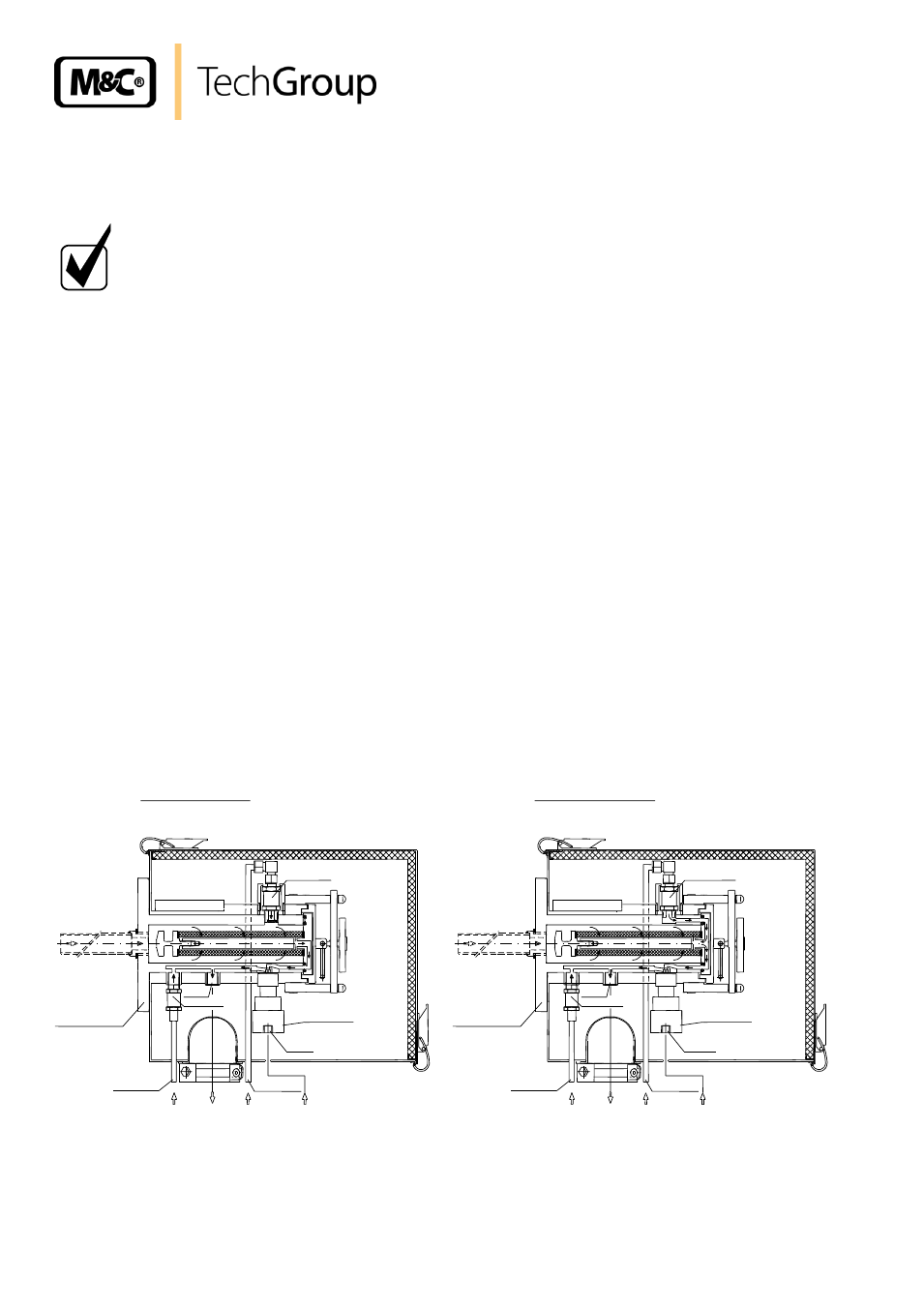

Pneumatic connexions, Figure 2, Connexions sp2200-h/c/i/bb and sp2200-h/c/i/bb/f – M&C TechGroup SP2200-H_C_I_BB_F Operator's manual User Manual

Page 14: 1 pneumatic connexions

14

Gas sampling and gas conditioning technology

2-1.1.6-ME

Now insert the process-internal probe section of the complete probe unit into the probe con-

nection, but first attach the flange seal to the probe connection and screw using the screws

and nuts supplied.

N O T E !

A preferred mounting position is to have the probe with its sample gas out-

let pointing downwards, although this is not absolutely necessary for per-

fect functioning. An advantage as well is mounting the probe with an angle

(10°) downwards.

12.1

PNEUMATIC CONNEXIONS

Remove the upper part of the sample line's mounting bracket and insert the sample line

through the silicon lid into the threaded pipe joint and connect it.

The temperature-resistant, stainless steel connectors supplied by M&C have a double ferrule

system to ensure reliable sealing. After tightening the nuts of these connectors by hand, they

should then be tightened exactly 1¼ of a turn using a flat spanner and are then properly

mounted.

If a PTFE tube is used as sample line, an insert must under all circumstances be inserted in

the end of the tube in order to prevent the tube being pressed together.

Screw on the upper part of the mounting bracket.

In the case of larger sample line diameters, it may be necessary for the central mounting of

the sample line to loosen the two screws and move the small mounting bracket of the mount-

ing bracket and then re-tighten them. Now place the heat conducting jaws around the sample

gas connection in the retaining slot and fix with the knurled nuts.

If the probe has a check valve /R for calibration gas feeding or backflush, the corresponding

pipe should be connected to the 6mm piping connection.

If the probe is fitted with an inlet ball valve with pneumatic drive, the control line for operating

the pneumatic controller element is to connected at the 1/8"-NPT connecting thread.

For safety reasons, the ball valve is to be closed before mounting the probe.

Now replace the protection shield and fasten using the pressure clamps.

(

P

3-10bar)

1/4"NP

T

(

P

>0,7bar)

1/8"NP

T

1/8"NP

T

(

P

3-10bar)

(

P

>0,7bar)

1/4"NP

T

SP2200-H/C/I/BB/F

Check valve

Isolation valve

Check valve

T

ube DN6/8

Blow back in

Sample out

Flange DN65 PN6

T

ube DN4/6

Cal.-gas in

Control in

Check valve

SP2200-H/C/I/BB

Control in

Sample out

T

ube DN6/8

Blow back in

Isolation valve

Flange DN65 PN6

Cal.-gas in

T

ube DN4/6

Check valve

Figure 2 Connexions SP2200-H/C/I/BB and SP2200-H/C/I/BB/F