Supply connections, Connecting the heated sample line, Figure 1 – M&C TechGroup PSP4000-H_C_T Operator's manual User Manual

Page 12: Connection of the heated sample line

12

Gas sampling and gas conditioning technology

2-2.1-ME

The existing operational parameters are to be checked accordingly prior to commencing mounting

work.

Under / over pressure situation

mbar

bar

Process temperature

°C,

Min.

°C,

Max.

Dust loading

g/m³

Dust composition - grain size

µm

Gas composition

corrosive

toxic

explosive

Which parameters should be

measured, e.g. O

2

, CO, SO

2

, NOX,....,

Vol.%

mg/Nm³

ppm

Required amount of gas

l/h,

Min.

l/h,

Max.

Necessary T

90

time

sec.

14

SUPPLY CONNECTIONS

14.1 CONNECTING THE HEATED SAMPLE LINE

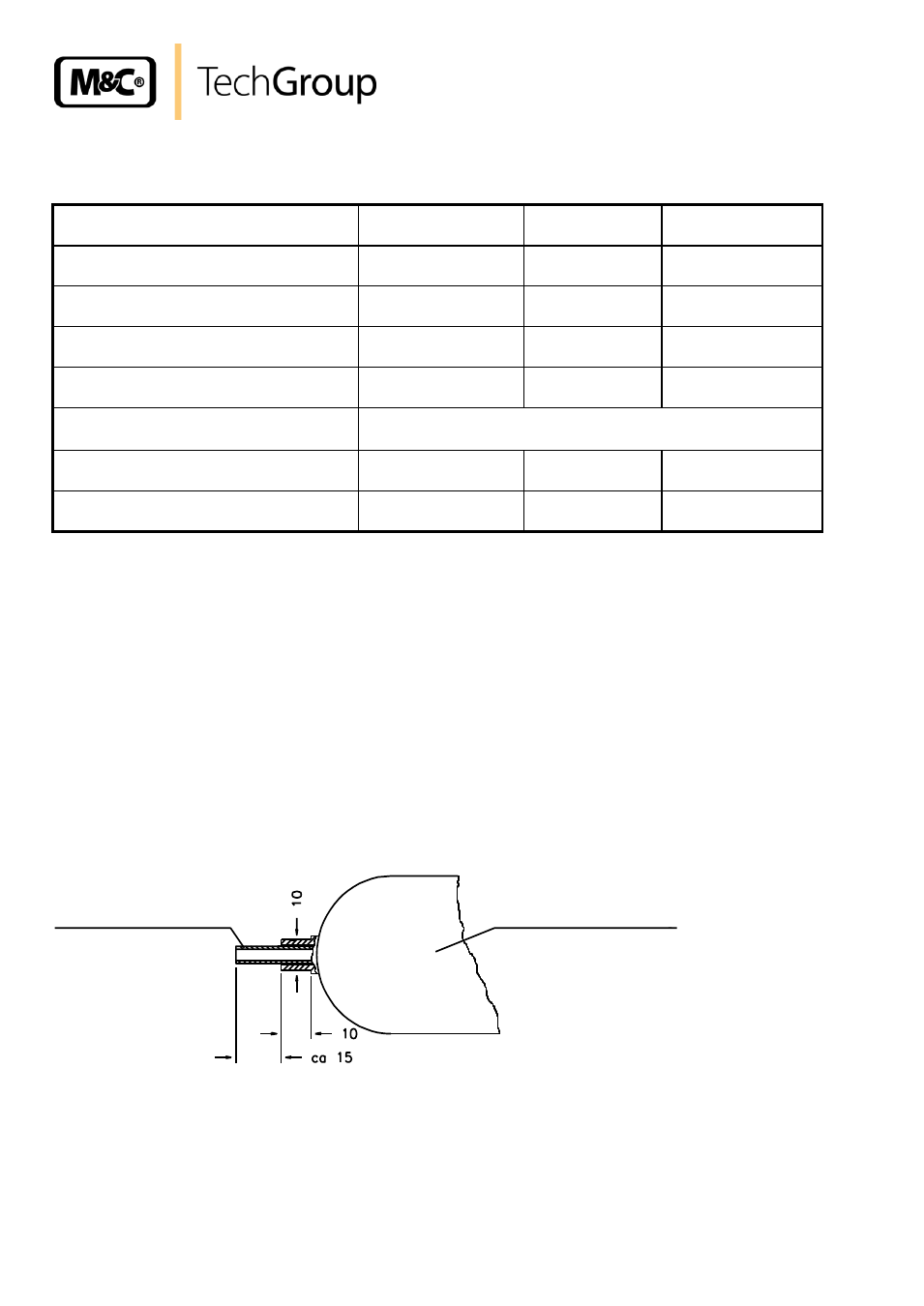

Remove the aluminium heat-conducting jaws at the probe's filter head by loosening the 4

screws from the gas outlet's threaded connection. The outlet's threaded connection is provided

for the connection of a tube with an external diameter of 6 mm (optionally 8 mm).

Before connecting a sample line not specified by M&C, the tube connection should be

prepared according to the following sketch.

M&C's heated sample lines type PSP 4M4/6 and PSP-W4M4/6 are manufactured to fit the

mechanical and electrical connections to the PSP4000-H... gas sample probe and already contain an

internal line for the probe's power supply.

Figure 1

Connection of the heated sample line

Push the insert into the PTFE tube in order to avoid the tube being compressed and slide the

red silicon protective ring up to the end of the heated sampling tube.

Introduce the PTFE tube into the threaded connection joint with the double-cutting ring system

to ensure sealing.

Heated sample line

PTFE-tube DN 4/6