Drawings + en, Ework positioning and restraint, Frope access – Petzl NAVAHO BOD CROLL FAST User Manual

Page 5: Stop

C71CFO NAVAHO BOD CROLL FAST C71503-A (011206)

E

WORK POSITIONING and RESTRAINT

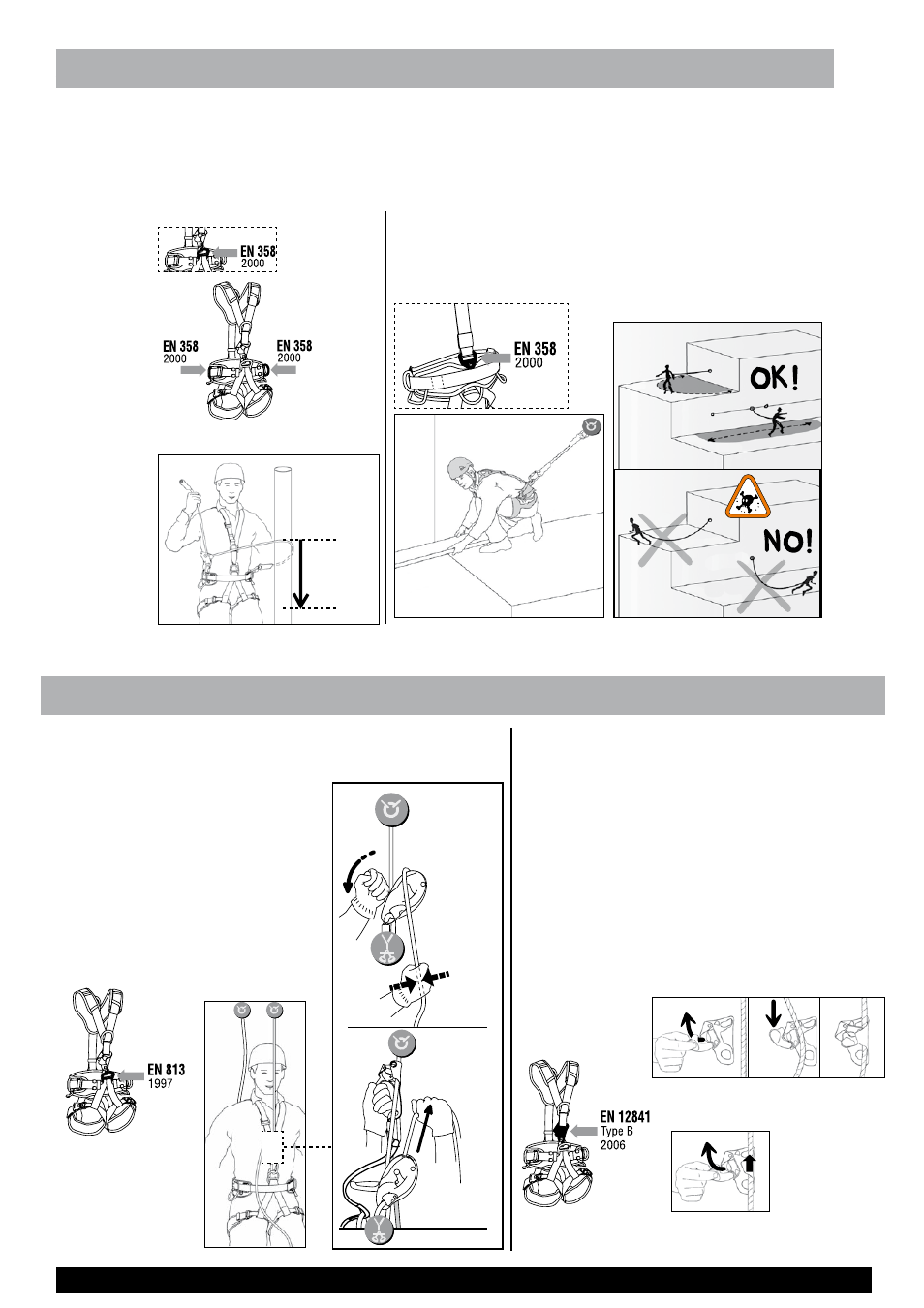

Diagram 4. EN 358: 2000 harness for work positioning and restraint

These attachment points are designed to either hold the user in position at the work-post (work in suspension), or to prevent the worker from entering a zone where a fall is

possible (leash principle). These attachment points must only be used to attach to a restraint or work positioning system, maximum fall height: 0,5 m.

These attachment points are not designed for fall arrest use and it may be necessary to supplement work positioning or restraint systems with collective fall arrest systems

(e.g. safety nets) or personal fall arrest systems (e.g. an EN 363 fall arrest system).

4C. Rear

restraint

attachment

point

This rear

attachment

point on

the belt is

intended only

to attach

a restraint

system that

keeps you

from entering

a zone

where the

risk of a fall

exists (leash

principle).

Regularly

verify the

length of

your restraint

and/or work

positioning

lanyard during

use.

4A. Ventral

attachment point

4B. Lateral belt

attachment points

Always use the

two lateral rings

together by clipping

a positioning lanyard

between them.

There should be a

supporting surface

for the feet for

comfortable work

positioning.

Adjust the work

positioning lanyard

so that the anchor

point is above or at

the same level as

the user’s waist. The

lanyard is kept under

tension and the free

fall distance is limited

to 0.5 m.

GRILLON

EN 358

Maximum

height of

fall : 0,5 m

4A.

4B.

4C.

Restraint only - No suspension

Example:

F

ROPE ACCESS

Ventral attachment point

The EN 813: 1997 standard

concerns seat harnesses that

are used in work positioning,

restraint, and rope access

systems when a low attachment

point is necessary.

Use this ventral ring to attach a

descender, positioning lanyards

or progression lanyards.

This attachment point should

not be used to attach fall arrest

systems.

I’D

or Type

C rope

adjustment

devices

ASCENSION

+ EN 354

LANYARD

I’D

Rope diameter

Use a 10-13 mm EN 1891 type A semi-

static kernmantel rope.

Diagram 6. Installation on the

rope

Pull the trigger/safety catch down and

out with the thumb and index finger. This

until it locks in place against the body of

the device. The cam is thus held open.

Put the rope into position. Push on the

safety catch until the cam swings into

place against the rope.

The safety catch helps prevent

involuntary opening of the cam.

STOP!

1

Field of application

The EN 12841: 2006 CROLL

rope clamp is a type B rope

adjuster used to ascend the

work rope.

ATTENTION, it must be

used with a type A backup

device on a second (safety)

rope (e.g. ASAP mobile fall

arrester for rope).

The CROLL ventral rope

clamp is not suitable for

use in an EN 363 fall arrest

system.

2

3

Removing

the rope

Move the

device up

the rope

while

pulling the

trigger/

safety

catch down

and out.

STOP!

1

2

Diagram 5. EN 813: 1997 seat harness

CROLL ventral rope clamp

EN 12841: 2006

Examples: