Wayne-Dalton TORQUEMASTER 9800 User Manual

Page 7

Tools Needed:

7

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer.

To find your Wayne-Dalton dealer; refer to your local yellow pages / business listings or go to Find a dealer area online at

www.wayne-dalton.com

PRE-INST

ALLA

TION

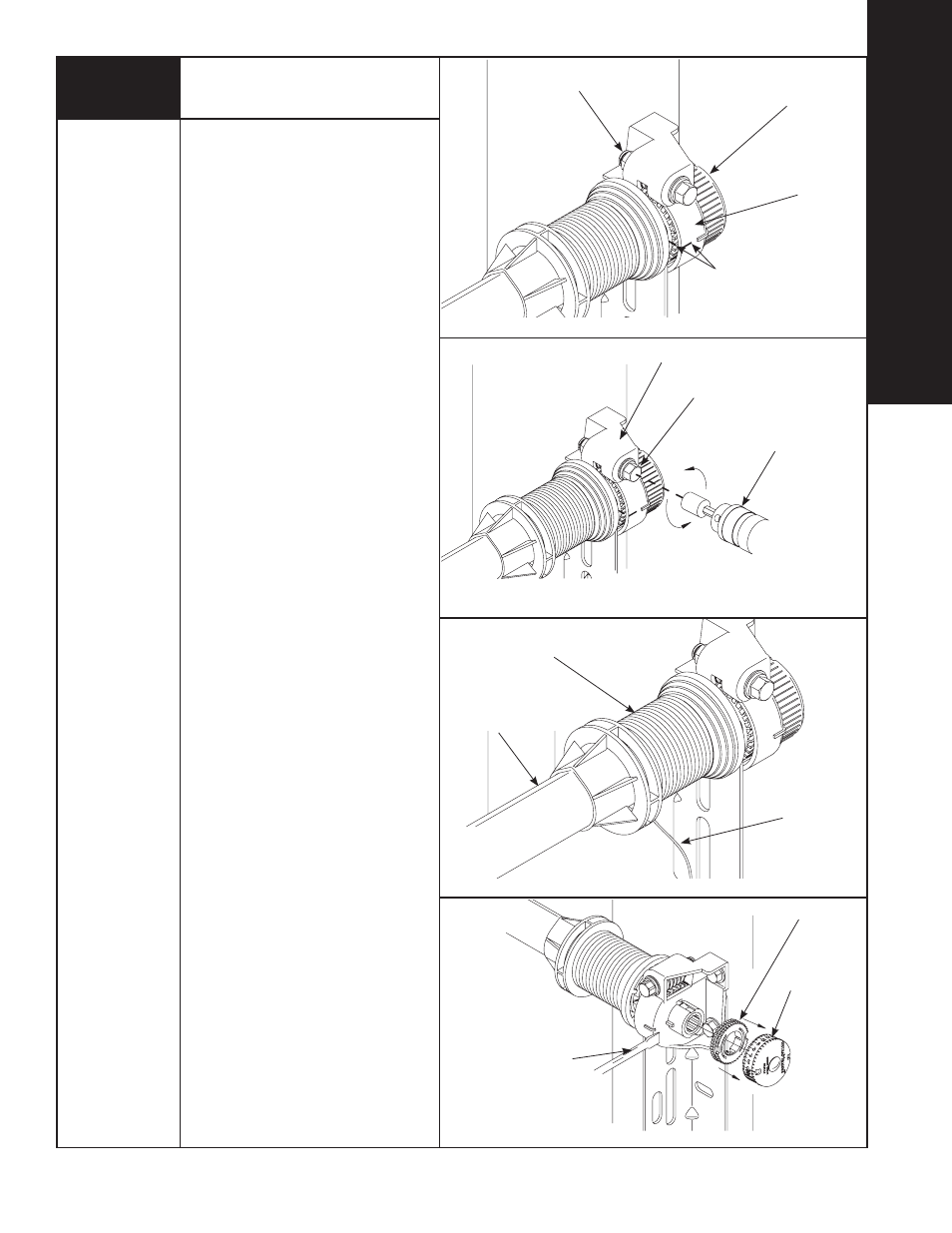

fig. 2

fig. 1

fig. 3

RIGhT haND

CablE DRuM

TORquEMasTER

®

sPRING TubE

ChECk CablE

TENsION

lOOsEN lOCk

NuT 1/4 TuRN

COuNTER

GEaR / COVER

RIGhT haND

END bRaCkET

PlaCE MaRk ON END bRaCkET

aND DRIVE GEaR TOOTh

bEFORE uNWINDING sPRINGs

END bRaCkET

RIGhT haND

WINDING bOlT hEaD

ElECTRIC DRIll

WITh 7/16” hEx

DRIVER (DO NOT

usE IMPaCT

GuN)

PRy COuNTER GEaR

aND COuNTER COVER

FROM END bRaCkET

usING FlaT TIP

sCREWDRIVER

COuNTER

GEaR

COuNTER

COVER

P2

a TorqueMaster

®

spring system can be

identified by the end brackets. For single

spring applications, the right hand end

bracket will always have a drive gear,

counter gear, counter cover, and a winding

bolt head. The left hand end bracket will

have no gears, counter cover, or winding

bolt head. The hole for the winding bolt

head will be plugged.

For double springs, both the right hand

and left hand end brackets will always

have a drive gear, counter gear, counter

cover and a winding bolt head.

IMPORTANT: RIGhT aND lEFT haND Is

alWays DETERMINED FROM INsIDE ThE

buIlDING lOOkING OuT.

Step 1: If you have a black counter

cover: Place a mark on the drive gear

tooth and an adjacent mark on the right

hand end bracket (Fig. 1). loosen the lock

nut 1/4 turn using a 7/16” wrench and

continue with step 2.

If you have a gray counter cover:

loosen the lock nut 1/4 turn using a 7/16”

wrench and continue with step 2.

Step 2: using an electric drill (high

torque / gear reduced to 1300 rpm

preferred) with a 7/16” hex head driver,

unwind the right hand winding bolt head

counterclockwise (Fig. 2) and count the

number of turns the mark on the drive

gear passes the adjacent mark on the end

bracket. Referencing the chart below, by

door height, stop unwinding the spring

once the counted turns have reached the

listed number of turns.

6’-0” Door height = 14 turns

6’-3” Door height = 14 1/2 turns

6’-5” Door height = 15 turns

6’-6” Door height = 15 turns

6’-8” Door height = 15 1/2 turns

6’-9” Door height = 15 1/2 turns

7’-0” Door height = 16 turns

7’-3” Door height = 16 1/2 turns

7’-6” Door height = 17 turns

7’-9” Door height = 17 1/2 turns

8’-0” Door height = 18 turns

CAUTION: DO NOT usE IMPaCT GuN TO

uNWIND sPRINGs.

IMPORTANT: DO NOT REFERENCE ThE

COuNTER COVER WhEN COuNTING ThE

NuMbER OF TuRNs bEING uNWOuND

ON ThE sPRING, buT FOllOW ThE

INsTRuCTIONs abOVE.

Step 3: Verify that spring tension has been

released by pulling the counterbalance

cable on the right hand cable drum away

from the header (Fig. 3). If spring tension

has been released, the cable will be loose.

In addition, the TorqueMaster

®

spring

Tube

TorqueMaster

®

Spring Removal

Recommended

tools from

page 5

fig. 4