Typical counter applications – Panasonic LC2H User Manual

Page 20

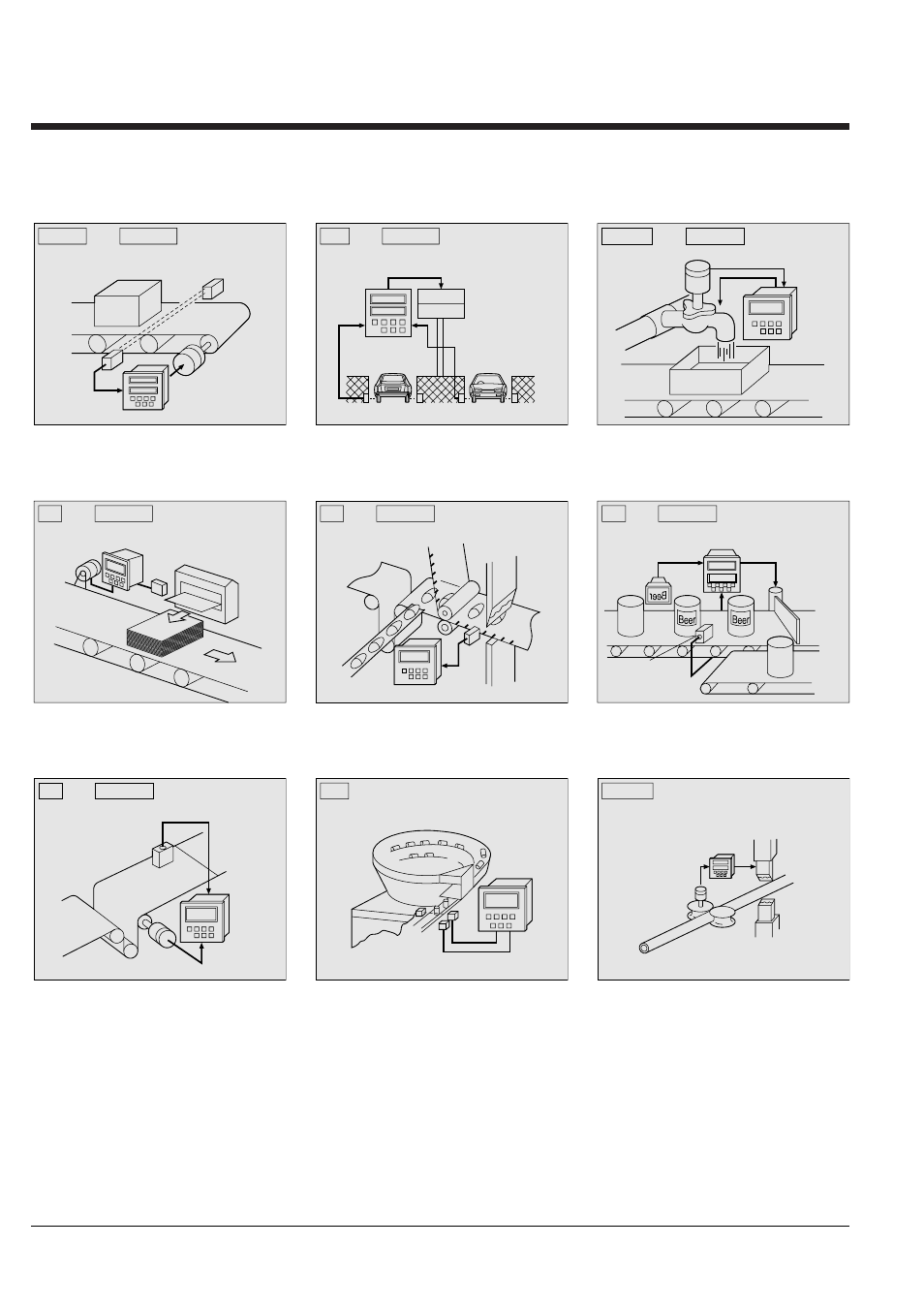

TYPICAL COUNTER APPLICATIONS

The highly accurate, reliable counters can be controlled from

the front panel and are suitable for a wide range of applications.

Photoelectric

switch

(stop/start)

Motor

DOWN and HOLD-A modes

for shipment quantity counting

Shipment quantities are counted to con-

trol the conveyor line flow.

Entrance

Exit

Photoelectric

(up count)

IN1

(down count)

IN2

FULL

VACANT

switch

IND and HOLD-D modes

for parking lots

Incoming and outgoing cars are counted

to switch the FULL and VACANT signs.

Rotary

To valve

encoder

PHASE and HOLD-A modes

for valve control

Rotary encoder signals are counted to

control a valve aperture.

Electric counter

Motor

Photoelectric

Printing

machine

switch

UP and SHOT-A modes

for packing a specified number of copies

Printed matter is counted to package a

specified number of copies.

Mark

sensor

Film

Marking

Cutter

UP and SHOT-B modes

for packing medicine tablets

Medicine tablets are packed in specified

quantities.

IN2

Mark sensor

Rejectables

Labeling

IN1

Acceptables

Sorting

(down count)

(up count)

machine

machine

UP and SHOT-C modes

for counting acceptables

Labeled cans alone are counted up.

Rejected cans are not counted.

IN2 (down count)

Rotary

IN1 (up count)

Leader sheet

Mark

sensor

encoder

(single-phase)

UP and SHOT-D modes

for winding leader sheet

Extra leader sheet that is now wound is

counted by a rotary encoder and a color

detecting sensor.

IN2

IN1

(counting)

(up/down count selection)

DIR input mode

for controlling part stocks

Incoming and outgoing parts are counted

to keep parts feeders well-stocked.

Pipe

Rotary

Electric counter

Cutter

encoder

PHASE input mode for sizing

Teamed up with a rotary encoder, the

counter is used to control the cutting

length of pipes.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: [email protected]