Lakeshore Learning Materials 622 User Manual

Page 22

Lake Shore Model 620/622/623/647 Magnet Power Supply User’s Manual

Setup & Connections

2-6

NOTE: The MPS includes a protection circuit which reduces the effect of open

sense leads during remote voltage sensing operation. If the +S lead opens, the

output voltage changes because it is sensed between +OUT and the negative

side of the load. If the –S lead opens, the output voltage changes because it is

sensed between the positive side of the load and –OUT. If both leads open, the

output voltage is sensed internally.

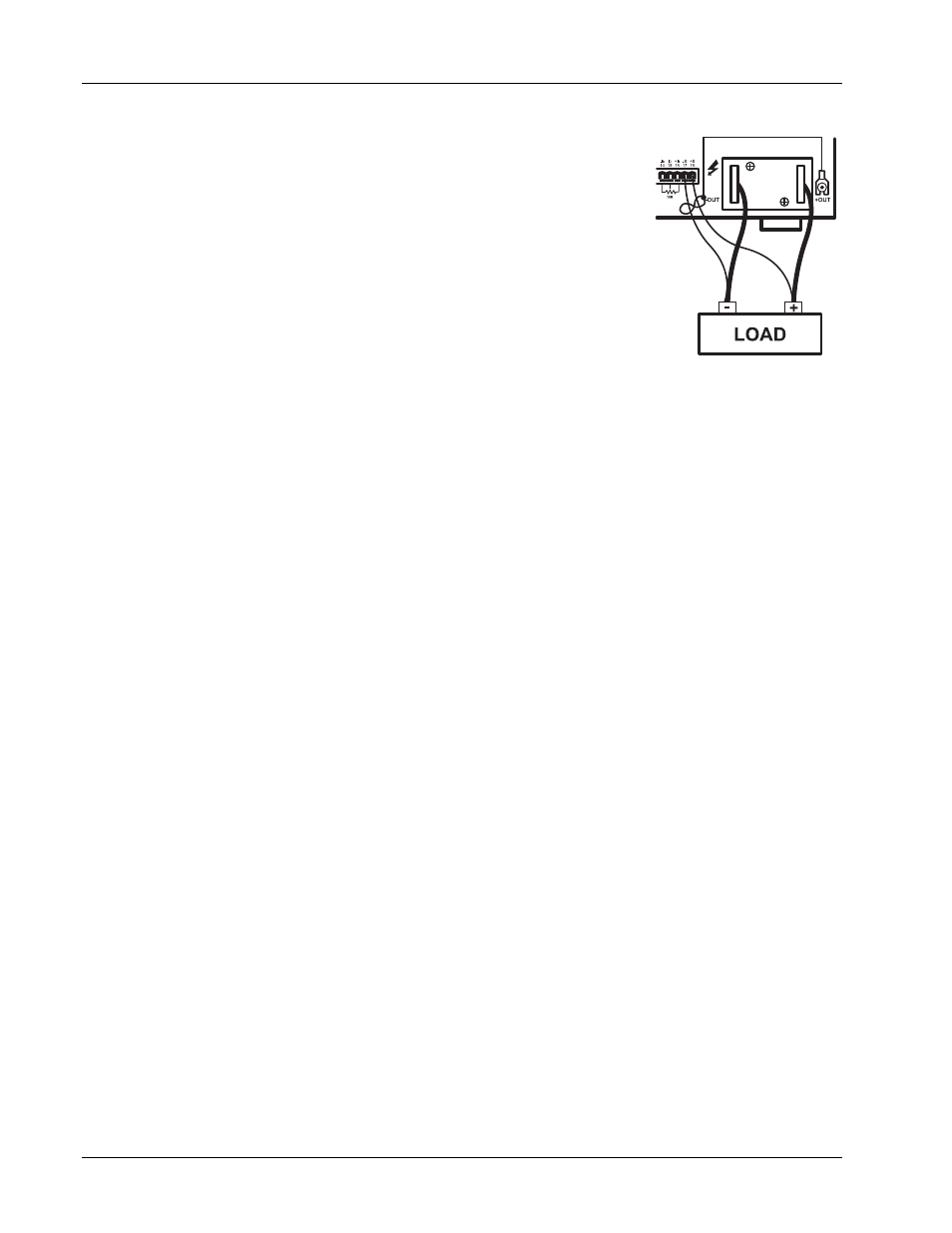

The procedure below configures the MPS for remote voltage sensing as shown

in Figure 2-3.

1. Turn off the unit.

2. If present, disconnect any wires between the +OUT and –OUT terminals

and the +S and –S connections on the MPS rear panel.

3. Connect the sense leads from the MPS +S and –S connections to the load.

Maintain polarity when making these connections.

CAUTION: Maintain polarity between +S and +OUT and –S and –OUT. The

+S and –S inputs control the output voltage. Improper polarity may apply

damaging voltages to the load.

4. Connect the ground shield to the mounting screw. Make sure that the shield does not come into electrical

contact with either magnet lead.

2.6 MULTIPLE AUTO-PARALLEL SETUP

Connect up to four MPS units in an auto-parallel configuration for increased output current capability. The

maximum total current allowed is the sum of the maximum currents of the individual units. For example four

623 MPS units provide 4

×

155 = 620 amps total current. The maximum total power is the sum of the

maximum power ratings of the individual units.

Assign each unit a unique address: 1 for MPS 1, 2 for MPS 2, etc. The MPS at address 1 polls the control bus

to determine if an auto-parallel configuration is present and how many MPS units are involved. When multiple

MPS units are present, MPS 1 sends the output current and voltage limits, ramp status, output current step

limit, and other operating parameters to the other MPS units so all units operate identically.

For two MPS configuration, each MPS is programmed for half of the total output current. This is true for the

ramp destination current and ramp rate. Each MPS contributes half the output current required. MPS 1

software polls MPS 2 to determine the total output current. The output voltage, current settings during a ramp,

and instrument status from MPS 1 are reported (since the values are the same for both units.)

NOTE: When multiple MPS units are present, install the Model 6228 persistent switch heater output option in

MPS 1 for proper operation.

An analog signal is also provided for remote activation of the output over voltage protection (OVP) circuit. The

signals connect in parallel so that the output OVP circuits of each MPS activate in unison.

CAUTION: Consult Lake Shore prior to operating multiple MPS units in auto-parallel mode.

Use the procedure below and see Figure 2-4 to connect multiple MPS units in auto-parallel configuration:

1. Turn off all units and completely disconnect power at the source before changing MPS configuration.

2. Determine which MPS to assign as MPS 1 and configure it as follows:

a. Locate the CAL AND ID DIP switches on the rear panel. Turn ON (up position) switches 1 and 4. Turn

OFF (down position) switches 2, 3, and 5 through 8. (Switch 4 ON designates multiple MPS operation.

Switches 3, 2, and 1 respectively OFF, OFF, and ON assign the MPS address as 1). Note that the

CAL AND ID switch numbers are upside down (as viewed from the rear panel). Switch 1 is on the right

and switch 8 is on the left. Take care to use the correct switch numbers.

b. Move the I MODE switch to the INTernal (up) position.

MPS Rear View

Maintain

polarity!

Connect -S

to -OUT and

+S to +OUT.

Figure 2-3. Remote

Sensing Connections