Lakeshore Learning Materials 622 User Manual

Page 15

Lake Shore Model 620/622/623/647 Magnet Power Supply User’s Manual

Introduction

1-5

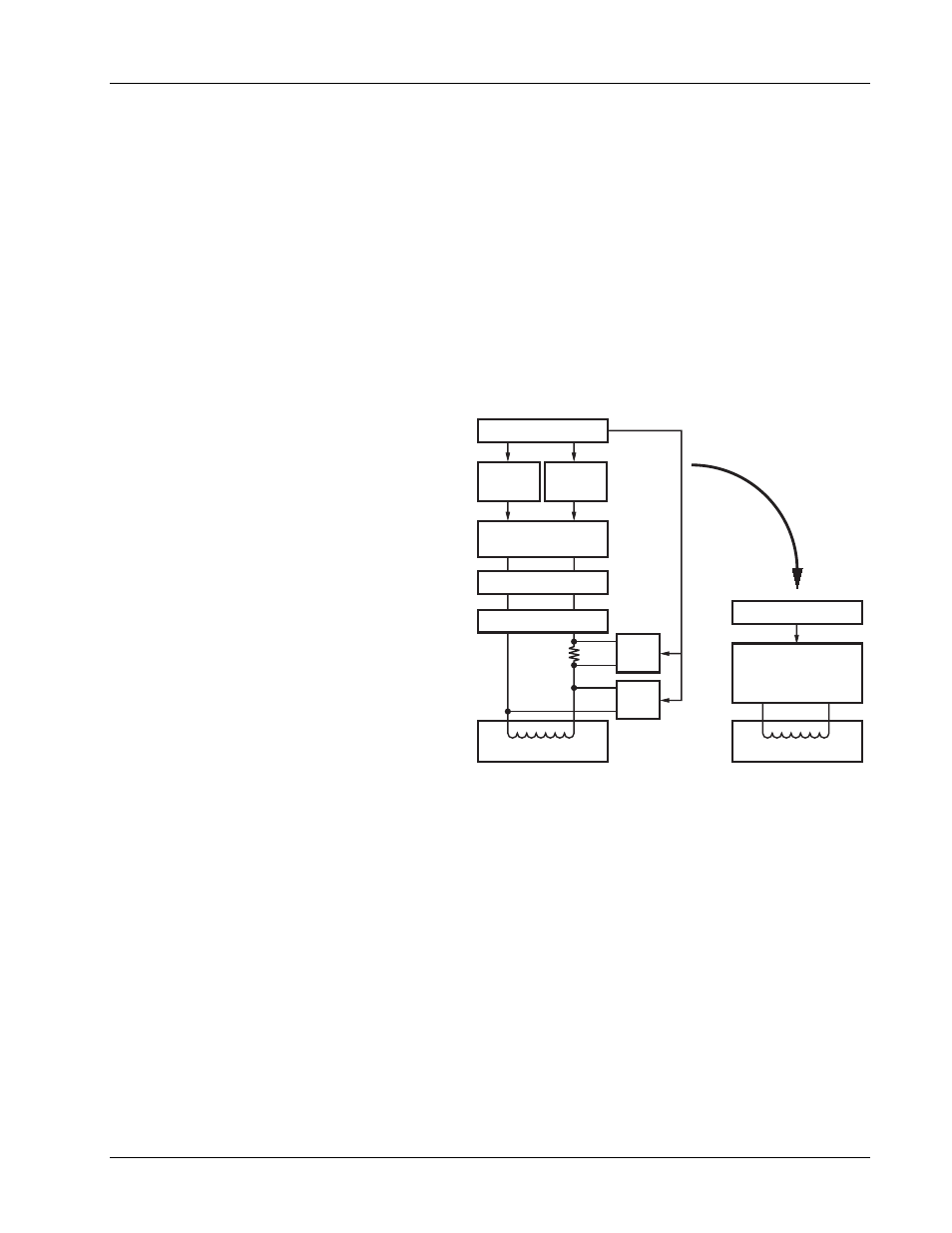

Conventional MPS: Consists of a unipolar power supply with an energy absorber to dissipate magnet energy

during discharge. The energy absorber prevents reverse voltage generated during the discharge from

damaging the unipolar supply output. Other conventional supplies dissipate magnet energy in the power

supply output transistor pass-bank. This two-quadrant performance requires the output stage to absorb

considerable power during the discharge. In addition, uniform charge and discharge rates are not always

ensured.

Current reversal requires external current reversal switches or manual lead reversal. These units provide

pseudo-four-quadrant operation which introduces discontinuities at the current reversal point produced by

switching the leads. Current reversal switches may incorporate direction detection diodes which reduce

available magnet charging voltage and dissipate additional power. Current reversal switches must also

interlock to prevent lead reversal when current is present. Current reversal switches complicate high power

cabling requirements, increase chances of introducing output current instabilities, and require time to reverse

leads. Manual lead reversal introduces discontinuity at the current reversal point. A discontinuous transition

through zero current may require a small external supply for near zero current analysis. Utility power failure in

a conventional supply generally results in a magnet quench.

1.3.2

Low Noise, High Stability Current Regulated Output

Lake Shore MPS: Maintains a high-stability,

low-noise, current-regulated output. Digital

setting and monitoring electronics, and

computer interfacing integrate into power

management and precision analog control

circuitry. This integration maintains high output

stability and repeatability. Extensive output

filtering and noise cancellation circuitry keep

MPS output noise very low. The MPS front

panel graphic display allows continuous display

of output current and voltage while setting

parameters from the menu-driven keypad. In

addition to the front panel and remote interface

programming, the MPS includes analog inputs

and outputs for setting and monitoring operating

parameters. The MPS requires only 7 inches of

rack space.

Conventional MPS: Some use a compliance

limited output with current monitoring to charge

the magnet. Others require output current to

drive against the output current limit to prevent

output current drift. Most use multi-turn

potentiometers and digital (or analog) panel

meters for front panel current and compliance

voltage setting. The elegance and repeatability of keypad entry is not available. There is no digital setting or

monitoring integration in the output control circuitry. Most achieve computer interfacing by adding computer

controlled voltage sources to analog program the output current and voltage. Additional inputs must be

added to digitize the output current and voltage. Setting and monitoring resolution is one to two orders of

magnitude poorer than the standard MPS provides. External setting and monitoring complicates cabling.

Degradation of the output current stability due to the addition of external cabling is undefined. Output noise

specifications are rarely given and sometimes vary with the type of magnet load driven. These multiple unit

configurations require up to 36 inches of rack space.

Magnet Load

Analog

Current

Programmer

Analog Programmed

Power Supply

Current Reversal

Energy Absorber

Analog

Voltage

Programmer

Computer

DVM

Current

Monitor

DVM

Voltage

Monitor

Magnet Load

Lake Shore MPS

True, Four-Quadrant

Bi-Directional

Power Flow

Computer

Now

Replaced

by:

Figure 1-2. Comparison of Old and New MPS Designs